- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

Automatic Shrinkage Tester Fully Automatic Fabric Washing Test Equipment D013N

Overview

Application

Standards

Key Parameters

|

Model |

D013N |

|

|

Load Weight |

10kg |

|

|

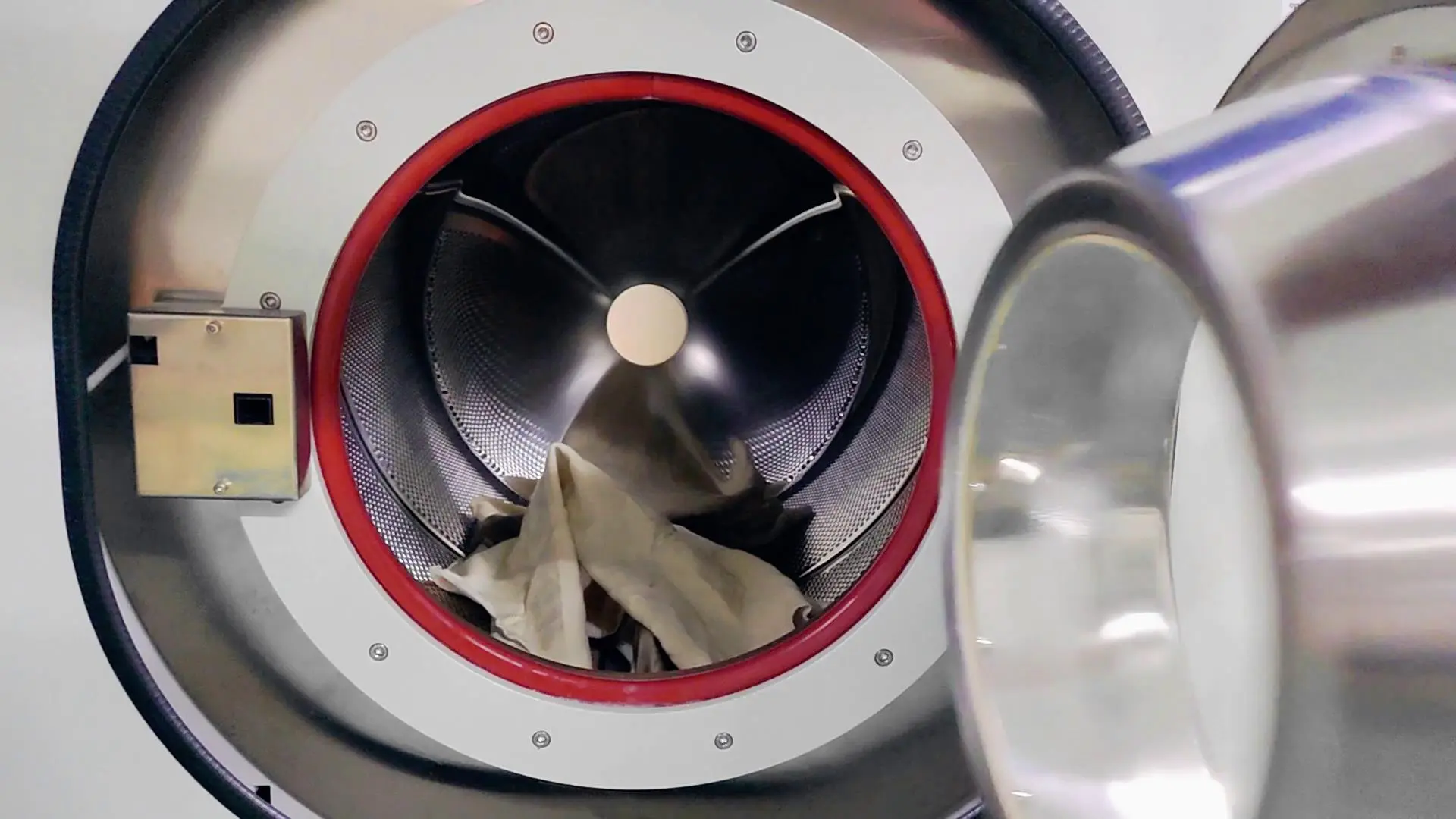

Inner cylinder |

Diameter |

(520±1)mm |

|

Depth |

(315±1)mm |

|

|

Net volume |

61L |

|

|

Lifter |

3 pieces. Height: 53±1mm. Interval: 120 degree Length: extends to the bottom of the inner barrel |

|

|

External cylinder |

Diameter (554±1)mm |

|

|

Test Speed |

Washing speed: 52±1rpm Low speed dehydration speed: 500±20 rpm High speed dehydration speed: 800±20 rpm |

|

|

Type |

Front door feeding, horizontal roller |

|

|

Height of inflow water level |

1-20cm, can be set |

|

|

Test temperature range |

RT - 99±1℃, can be set |

|

|

Temperature control fluctuation |

<±1℃ |

|

|

Heating Power |

5.4KW |

|

|

Rotary action |

Normal rotation time interval :(12±0.1) s Normal stop time interval :(3±0.1) s Moderate rotation time interval :(8±0.1) s Interval of remission stop :(7±0.1) s Soft rotation time interval :(3±0.1) s Soft stop time interval :(12±0.1) s |

|

|

Water supply system |

Water supply flow: (20±2) L/min(the water supply pressure at the inlet shall be higher than 150 kP) Water level detection: 100mm and 130mm at grade 2 (tolerance ≤3 mm) Drainage rate: > 30 L/min |

|

|

Washing procedure |

Built-in 13 sets of GB/T 8629 procedures; 13 sets of ISO 6330 procedures; 3 sets of custom procedures; 1 set of manual single program. |

|

|

Door swtich |

Auto open and close |

|

|

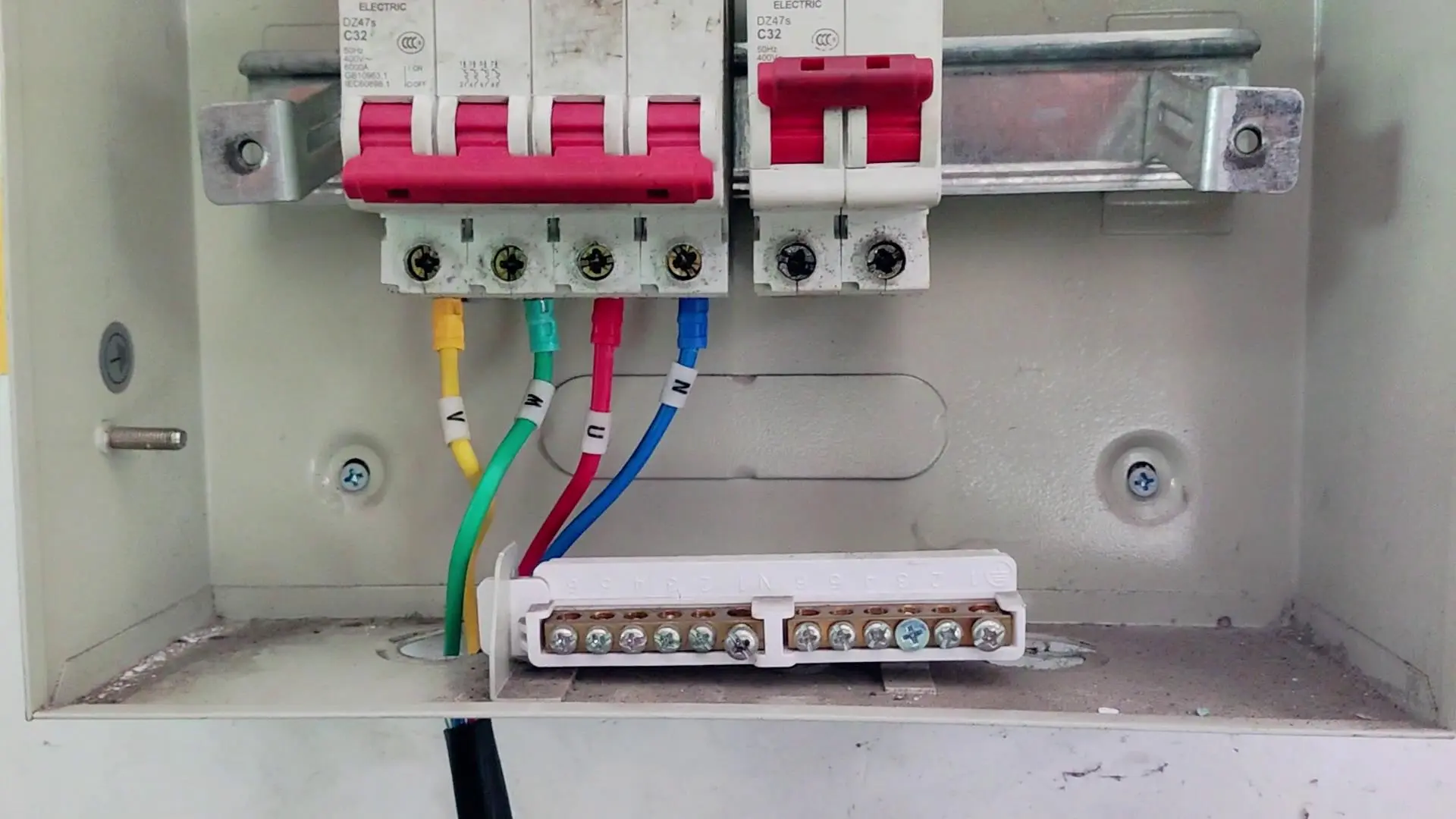

Power Supply |

AC 380V 50Hz 6.5KW (customized AC 220V 50Hz 6.5KW) |

|

|

Dimension |

820×740×1340mm(L×W×H) |

|

|

Weight |

240kg |

|

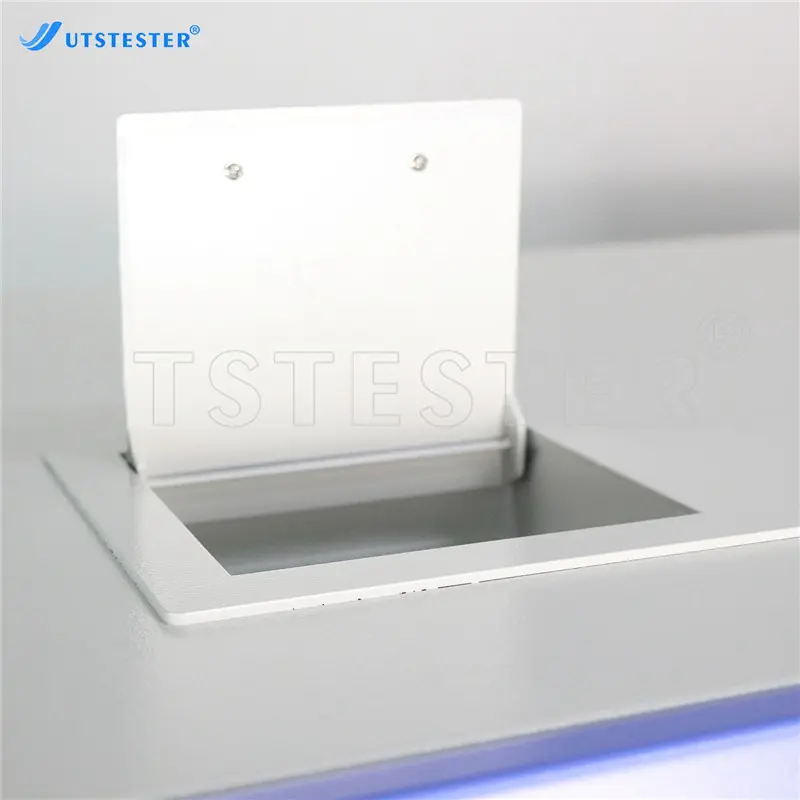

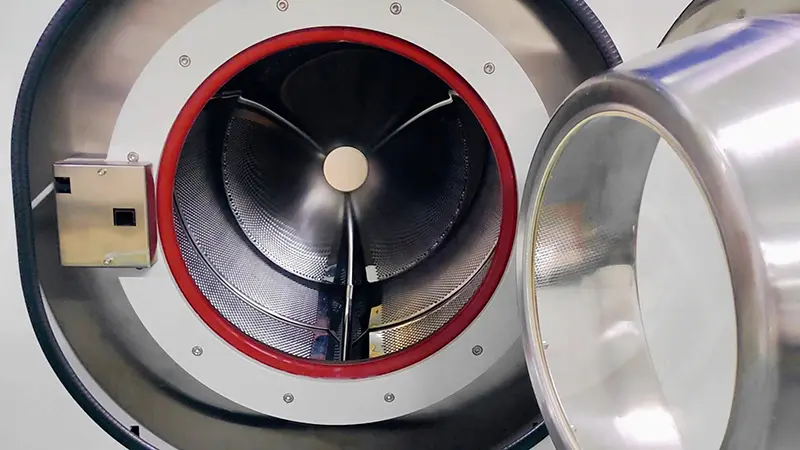

Product Details

Production Processes

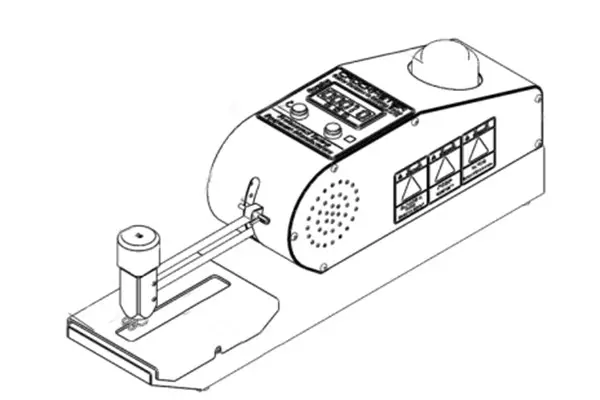

Scenarios of Use

Operation

Transportation

Home

Home