Home

Home

In the rapidly evolving landscape of the textile industry, selecting the right **Textile Testing Equipment** is crucial for ensuring quality and performance. As an essential component for manufacturers, researchers, and quality control professionals, these tools enable precise measurement and analysis of fabric properties. Renowned textile expert Dr. Emily Green once stated, "The right testing equipment provides the foundation for innovation and excellence in textile production." Her words underscore the importance of making informed choices in the acquisition of testing devices.

As we approach 2025, the need for advanced and reliable **Textile Testing Equipment** has become more pronounced. Factors such as emerging technologies, stringent quality standards, and consumer expectations drive the necessity for equipment that not only meets industrial benchmarks but also adapts to new challenges. Understanding how to evaluate and select the correct tools is key for stakeholders aiming to enhance their operational efficiency and product quality.

In this guide, we will explore critical considerations when choosing **Textile Testing Equipment**, from understanding specific testing methodologies to evaluating features that align with your testing needs. By focusing on the latest trends and expert insights, this guide aims to equip you with the knowledge needed to make informed investments in textile testing technology.

In 2025, the significance of textile testing equipment has become even more pronounced as the industry faces increasing challenges related to quality assurance and regulatory compliance. As consumer awareness grows, so does the demand for textiles that not only meet aesthetic and functional requirements but also adhere to safety and sustainability standards. Textile testing equipment plays a crucial role in this landscape, enabling manufacturers and suppliers to evaluate the physical and chemical properties of fabrics accurately.

Moreover, advancements in technology have led to the development of sophisticated testing instruments that provide more reliable and precise results. This is essential for companies aiming to optimize their production processes and minimize defects. The data gathered from these tests not only informs product development but also enhances supply chain transparency, allowing stakeholders to make informed decisions. In a competitive market, investing in the right textile testing equipment can significantly impact a company's reputation, customer satisfaction, and overall success.

When selecting textile testing equipment, it is crucial to assess several key factors to ensure the best fit for your specific needs. First and foremost, the type of testing required must align with the end goals of your textile quality control process. For instance, the market analysis conducted by the Textile World Forum indicates that over 60% of textile manufacturers prioritize fabric strength and durability testing, which highlights the need for equipment that can accurately perform tensile and tearing strength assessments.

Moreover, precision and accuracy are fundamental when considering textile testing equipment. According to a report by the International Textile and Apparel Association (ITAA), a mere 0.5% margin of error in testing can lead to significant discrepancies in product quality. Therefore, investing in equipment with ISO and ASTM certification ensures that the tests conducted will produce reliable results, ultimately saving time and resources in rework and returns.

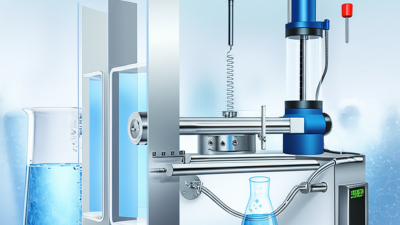

Additionally, the adaptability of the equipment to various fabric types should be considered. With the rise of specialized textiles such as smart fabrics and eco-friendly materials, having versatile testing equipment can enhance laboratory efficiency. The Global Textile Testing Market Analysis underscores the importance of multifunctional equipment, noting that companies utilizing adaptable machines report a 25% increase in productivity, allowing for a broad spectrum of testing capabilities without the need for multiple devices.

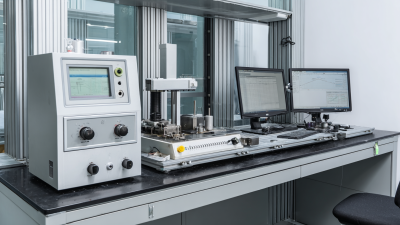

When selecting textile testing equipment, it is essential to understand the various types available and their specific applications to ensure accurate results. One of the primary categories of equipment is strength testing machines, which are crucial for determining the tensile, tear, and burst strength of textiles. According to a report by Technavio, the increasing demand for durable fabrics has propelled the market for strength testing machines, with an expected growth of 5% annually between 2021 and 2025. These machines provide essential data for manufacturers to meet industry standards and consumer expectations.

Another critical type of textile testing equipment is color fastness testing machines, which assess how well fabrics retain their color when exposed to washing, light, or rubbing. The global market for color fastness testing is anticipated to grow significantly, reflecting the growing emphasis on quality control in the textile sector. A recent study indicated that over 60% of consumers consider color durability a key factor in their purchasing decisions. By investing in reliable color fastness testing equipment, manufacturers can enhance product quality and customer satisfaction while reducing returns and complaints.

In addition, moisture management testing devices are increasingly important, particularly for performance fabrics used in activewear and sports applications. These devices evaluate how well textiles wick moisture and provide comfort to end-users. With the rise of smart textiles, the moisture management equipment market is projected to expand rapidly, with a compound annual growth rate (CAGR) of 7.2% through 2025, according to industry forecasts. Understanding the specific uses of these diverse types of textile testing equipment is vital for businesses aiming to uphold standards and innovate within the industry.

When planning to invest in textile testing equipment in 2025, it’s crucial to establish a clear and comprehensive budget. Start by assessing your specific testing requirements and the types of fabrics you will be working with. This will help you determine the necessary features and capabilities of the equipment you need. Next, consider the total cost of ownership, which includes initial purchase price, maintenance, and potential upgrades. Allocating funds for training staff to effectively use the equipment is also essential.

Tips: Always set aside a portion of your budget for unexpected expenses. This could include repairs or additional features that may become necessary as your testing needs evolve. Research funding options or grants available for textile testing innovations, which can ease the financial burden.

Additionally, prioritize your budget items based on their importance to your operational goals. If a certain type of testing is crucial for quality assurance, it may warrant more investment than others. Don't overlook the potential benefits of multi-functional equipment, as it can save both space and costs in the long run, leading to more efficient resource management within your facility.

When evaluating textile testing equipment, understanding product quality and brand reputation is crucial for making informed decisions. According to a report by the American Association of Textile Chemists and Colorists (AATCC), approximately 30% of textile manufacturers experience significant financial losses due to inadequate testing. Hence, ensuring that your equipment meets industry standards becomes imperative. Look for testing solutions that comply with ISO and ASTM standards, as these certifications not only validate the quality of the equipment but also enhance reliability in results.

Brand reputation plays a significant role in the textile testing equipment market. A recent survey by Market Research Future indicated that 62% of textile manufacturers prefer suppliers with well-established reputations for quality and service. Brands with a proven track record often provide better customer support and maintain higher levels of product innovation. When choosing equipment, consider companies that consistently receive positive feedback regarding their reliability and after-sales service, as this reflects not only on the equipment itself but also on the company’s commitment to quality and customer satisfaction. Engaging with industry forums and reading reviews can provide additional insights into brand reputation, ensuring that you make a choice that supports your quality assurance goals.