Home

Home

The importance of a Friction Tester Machine in various industries cannot be overstated. According to Dr. Emily Johnson, a leading expert in materials testing, "Understanding friction characteristics is crucial for product safety and performance." This statement highlights the essential role friction testing plays in quality control.

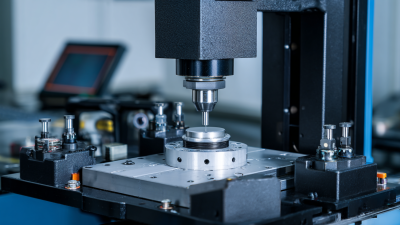

Friction Tester Machines can improve safety, efficiency, and overall product quality. In industries like automotive and manufacturing, these machines measure friction coefficients accurately. They help identify materials that work well together or may lead to wear and tear. Without this data, products may fail unexpectedly.

However, using a Friction Tester Machine has challenges. Test environments can introduce variability. Ensuring accuracy requires regular calibration and maintenance. Despite these hurdles, the benefits often outweigh the drawbacks. A consistent approach to friction testing can lead to innovations in design and materials. Embracing these machines can transform the way companies understand friction’s role in their products.

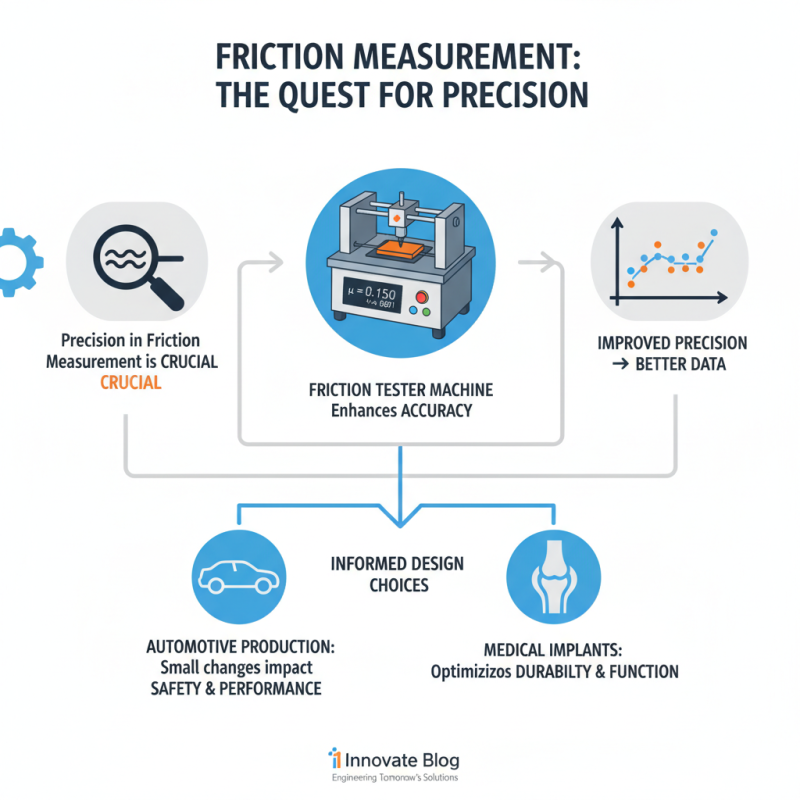

Precision in friction measurement is crucial for various industries. A friction tester machine enhances accuracy during tests. The improved precision leads to better data collection. This data can inform design choices in various applications. For example, in automotive production, small changes in friction can impact safety and performance.

The machinery’s enhanced calibration capabilities result in consistent readings. This reduces variability in measurements, making it easier to identify trends. Observing these trends helps engineers to make informed adjustments. Yet, not all operators use the machines correctly. Sometimes settings are overlooked, leading to erroneous results. Regular training is essential but often neglected.

Accurate friction measurements can optimize product quality. However, misunderstandings of the machine’s functions can hinder this process. Each test is a chance to learn and improve. When mistakes are made, they should lead to reflection and adaptation. Embracing this mindset drives progress and accuracy in friction testing.

Accurate friction testing provides vital insights into material performance. Friction testers measure the coefficient of friction between materials. This data helps in selecting the right materials for various applications. A suitable material can mean the difference between success and failure in a project.

When conducting friction tests, ensure your samples are representative. Any deviation could lead to misleading results. Pay attention to surface conditions. Small scratches or impurities can alter outcomes. Choosing the right testing environment is also essential. Ambient temperature and humidity can affect friction values.

Tips: Always calibrate your equipment before use. This helps maintain accuracy and reliability. Document your testing process carefully. Re-evaluating your methods can unveil unexpected issues. Engaging in regular training can enhance your team's understanding of friction testing. Remember, every detail counts in achieving the best results.

Friction testers play a crucial role in evaluating wear and tear in mechanical components. By analyzing friction data, manufacturers can make informed decisions on material selection. According to industry reports, friction testing can reduce component wear by up to 30%. This reduction is vital for prolonging the life of machinery and minimizing maintenance costs.

Understanding the friction coefficients of materials allows engineers to create better designs. For instance, a lower friction coefficient indicates less wear. However, relying solely on friction data can lead to oversights. Sometimes, materials that perform well in tests may not replicate the same results under dynamic conditions. Hence, cross-referencing multiple data sources is essential.

Tips for effective friction testing:

Friction testing is vital in many industries. It significantly impacts safety standards. By using friction tester machines, companies can conduct rigorous analyses. These analyses help identify potential hazards in materials and components. A precise friction analysis can reveal where materials may slip or fail. This knowledge is crucial for enhancing safety.

Incorporating friction testing in design processes can prevent accidents. For example, if a product does not meet friction requirements, it could lead to dangerous situations. Sometimes, companies overlook these tests, assuming their materials will perform adequately. However, this assumption can be misleading and costly.

Furthermore, understanding friction properties aids in the selection of materials. Engineers can choose components that work well together, minimizing risks. This proactive approach improves overall product reliability. Yet, testing must be thorough and continual. It is not a one-time task; it requires vigilance and adaptation. Safe designs emerge from this commitment to excellence.

The friction tester machine offers significant advantages in cost efficiency during production. A key aspect is minimizing material failures. According to industry reports, up to 30% of materials fail due to improper friction properties. Addressing these failures early saves companies thousands of dollars in waste and rework.

Moreover, manufacturers can enhance product quality. A study showed that testing with friction testers reduces defects by 25%. This proactive approach prevents costly recalls and protects brand reputation. However, companies often overlook the initial investment in testing equipment. This mindset can lead to higher long-term costs.

Additionally, many firms underestimate the impact of friction on performance. For instance, various materials exhibit different friction behaviors under stress. Neglecting this can result in unexpected breakages or malfunctions. Regular testing can provide insights that lead to better material choices and designs. Yet, some organizations may struggle to embrace these testing processes fully. A better understanding of friction dynamics is necessary for innovation and efficiency.

| Benefit | Description | Impact on Cost Efficiency |

|---|---|---|

| Minimizes Material Failures | Identifies potential material defects before production. | Reduces waste and rework costs. |

| Improves Product Quality | Ensures materials meet quality standards and performance criteria. | Enhances customer satisfaction and reduces returns. |

| Streamlines Testing Process | Automates and standardizes testing protocols. | Saves time and labor costs. |

| Enhances Process Control | Provides real-time data for monitoring production processes. | Optimizes resource allocation. |

| Increases Efficiency | Reduces time spent on manual testing. | Boosts overall productivity. |

| Facilitates Compliance | Helps in meeting industry standards and regulations. | Avoids fines and enhances brand reputation. |

| Encourages Innovation | Supports research and development of new materials. | Drives future growth and market competitiveness. |

| Reduces Variation | Minimizes discrepancies in material performance. | Enhances consistency in production outputs. |

| Provides Detailed Insights | Delivers comprehensive data analysis for decision making. | Informs strategic planning and reduces risk. |

| Improves Safety Standards | Identifies unsafe materials quickly. | Protects workers and reduces liability. |