Home

Home

In the ever-evolving field of technology, the importance of Cof Testing Equipment cannot be overstated. According to industry reports, the global market for testing equipment is projected to reach $35 billion by 2025. This reflects a growing demand for precision and reliability in various sectors, including electronics and manufacturing. Choosing the right equipment is crucial for ensuring quality and productivity.

However, the process can be challenging. Many organizations overlook critical factors when selecting Cof Testing Equipment. This oversight may lead to suboptimal performance and increased costs. A recent survey indicated that 45% of companies do not regularly evaluate their testing tools. As such, the need for a strategic approach in choosing these tools has never been more essential.

Understanding the specific needs of your business is vital. Customization should not be a luxury; it must be the norm. Resistance to adapt can result in wasted investments. Remember, the right equipment could significantly enhance testing accuracy. It could also streamline operations significantly, paving the way for innovation and growth.

When selecting COF testing equipment, accuracy is critical. The equipment should measure the coefficient of friction precisely. Look for devices that offer reliable results across various materials. This ensures that the readings you obtain reflect actual performance. Repeatability is another key factor. You want equipment that provides consistent results over multiple tests. Inconsistent data can lead to poor decision-making.

Consider the user interface of the testing equipment. A complex interface can lead to user errors. It should be intuitive and easy to navigate. Ease of use will minimize mistakes. Additionally, check the maintenance requirements. Some devices may need frequent calibration or care. High-maintenance equipment may not be practical for all labs.

Evaluate the support offered by the manufacturer. Technical support can help resolve issues quickly. Training resources can also be beneficial for new users. While cost is always a factor, cheaper options may compromise quality. Investing in reliable equipment can lead to better long-term outcomes. Focusing on these elements will guide you in making a more informed choice.

| Factor | Description | Considerations |

|---|---|---|

| Measurement Range | The range of COF values the equipment can measure. | Ensure it covers the expected range for your materials. |

| Testing Speed | The speed at which the equipment performs tests. | Consider your workflow and how quickly results are needed. |

| Precision and Accuracy | The degree to which the results reflect true values. | Verify calibration and validation processes of the equipment. |

| Ease of Use | How user-friendly the equipment is for operators. | Look for intuitive interfaces and minimal training requirements. |

| Maintenance Requirements | The frequency and type of maintenance needed to keep the equipment operational. | Consider cost and time involved in maintenance. |

| Compliance Standards | Regulatory standards that the equipment must meet. | Check for ISO certifications and industry-specific requirements. |

| Cost | Total price including purchase, setup, and operational costs. | Evaluate your budget and compare against features offered. |

When selecting COF (Coefficient of Friction) testing equipment, understanding the types available is crucial. There are mainly two categories: dynamic and static COF testers. Dynamic testers measure friction during motion, while static testers gauge resistance before movement. This distinction is vital for applications in packaging, automotive, and electronics. A recent report highlighted that over 60% of manufacturers prefer dynamic testing to evaluate material performance under real-world conditions.

Each type of COF testing equipment serves specific applications. For instance, dynamic testers are essential in assessing surfaces that require sliding movement, such as packaging films. Static testers often find their place in evaluating adhesive strength for tapes and labels. According to industry data, around 75% of product failures in the packaging sector result from inadequate COF measurements. This highlights the need for precise testing equipment that aligns with specific material requirements.

However, challenges exist in choosing the right equipment. Not all devices offer the same accuracy or reliability. Some may yield inconsistent results, leading to product quality issues. It's crucial to review equipment calibration standards and ensure they meet established guidelines. Skipping this step can be detrimental. Many companies invest in equipment without proper validation, impacting their production efficiency.

This chart illustrates the different types of COF testing equipment and the number of applications associated with each type. The Static Friction Tester leads with the highest number of applications, highlighting its importance in material testing and analysis.

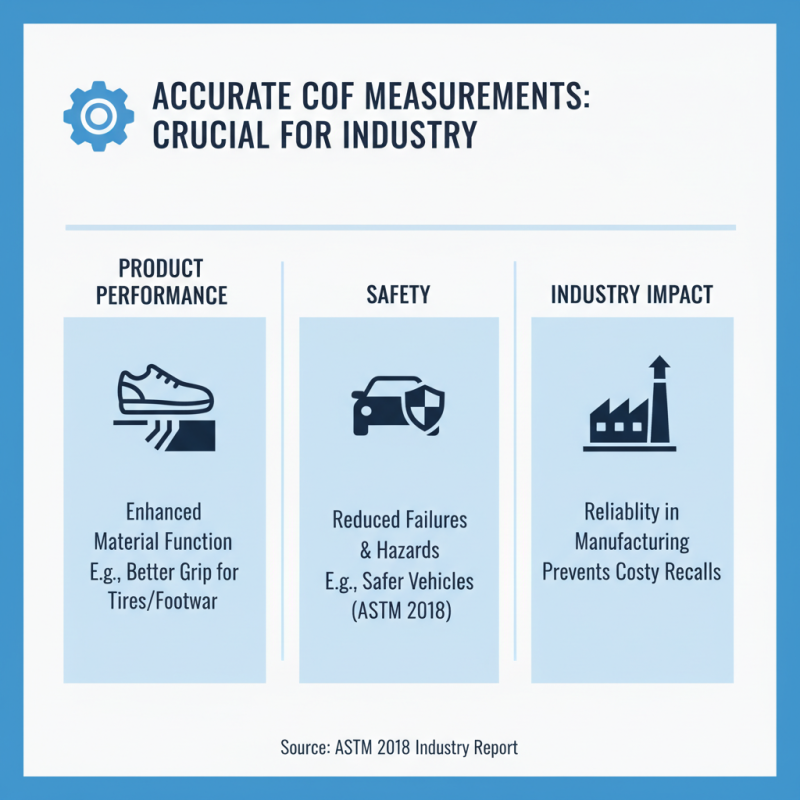

Accuracy in COF measurements is crucial for various industries. The coefficient of friction (COF) impacts product performance and safety. For instance, a 2018 industry report by the American Society for Testing and Materials (ASTM) emphasized that precise COF values are essential for designing safer vehicles and enhancing material performance. A slight error in measurement can result in product failures or safety hazards.

Selecting the right testing equipment is not straightforward. It requires understanding specific testing methods and equipment types. For example, dynamic and static friction tests each have unique requirements. A common pitfall is assuming that one equipment type fits all scenarios. Inadequate knowledge about the testing environment can lead to incorrect readings.

Additionally, the calibration of testing devices must be regularly checked. Ignoring this can undermine the reliability of COF results. A study by the International Organization for Standardization (ISO) highlighted that nearly 30% of testing failures were due to improper calibration. This reflects a need for continuous improvement in measurement accuracy and equipment choice.

When considering COF testing equipment, budget is a key factor. The costs can vary widely. A basic setup may start around $5,000. Advanced systems can exceed $50,000. Knowing your needs helps narrow down choices. Essential features may include accuracy and reliability. However, adding more functions increases the cost significantly.

Research shows that around 30% of laboratories overspend on equipment that exceeds their requirements. Investing wisely can prevent this. For instance, a study highlighted that 40% of users found their initial choice unsuitable after a year. They faced unexpected maintenance costs that strained their budgets. Regular maintenance can add another 10-15% to the total cost of ownership.

It's essential to weigh the budget against your testing demands. Don't forget hidden costs like calibration and training. Address these concerns early on. Adjusting your specifications might help fit within your financial framework. This strategic approach can lead to a more productive and cost-effective testing process.

When selecting COF testing equipment, proper maintenance and calibration are crucial. Regular checks ensure the equipment operates accurately. Calibration should align with manufacturer specifications. Incorrect calibration can lead to faulty data. This can ultimately affect product quality.

Routine maintenance is essential for longevity. Inspect parts regularly for wear and tear. Replace worn components promptly. Some users underestimate the importance of cleanliness. A dirty device can skew results. Use compressed air to clear dust and debris.

Documentation is key. Keep a record of all calibration and maintenance activities. This helps track equipment performance over time. You may notice inconsistencies that require attention. Recognizing these patterns is vital for continuous improvement. A proactive approach ensures that your testing equipment remains reliable.