Home

Home

Textile Lab Equipment plays a pivotal role in the textile industry by ensuring the quality and performance of fabrics and fibers through rigorous testing. As the demand for high-quality textiles rises, the significance of comprehensive testing procedures becomes paramount. Utilizing advanced testing equipment in textiles allows manufacturers to accurately assess various properties, such as strength, durability, and colorfastness. This vital equipment not only facilitates the evaluation of raw materials but also helps in maintaining consistent quality throughout the production process, ultimately leading to higher customer satisfaction and brand loyalty.

The importance of Textile Lab Equipment extends beyond mere compliance with industry standards; it enables textile professionals to innovate and enhance product performance. By using sophisticated instruments and testing methods, researchers and manufacturers can develop new textiles that meet specific market needs, such as moisture management, breathability, and eco-friendliness. In a competitive marketplace, the ability to conduct reliable testing and analysis using specialized lab equipment can set a company apart from its competitors. Consequently, investing in state-of-the-art Textile Lab Equipment is essential for any textile business aiming to thrive in today's evolving landscape.

Textile lab equipment refers to the tools and instruments used in the analysis, testing, and quality assurance of textile materials and products. This equipment plays a vital role in ensuring that textiles meet industry standards and consumer expectations. Functions of textile lab equipment range from evaluating the physical properties of fibers and fabrics to assessing performance characteristics like durability, colorfastness, and moisture management.

For instance, tensile testing machines evaluate the strength and elasticity of fabrics, providing critical data that manufacturers need to produce reliable products. According to a report by Smithers Pira, the global textile testing market is projected to grow at a CAGR of 5.2% from 2021 to 2026, highlighting the increasing reliance on rigorous testing standards to mitigate risks in textile production. Additionally, color measurement instruments, such as spectrophotometers, ensure that dyeing processes result in consistent color outcomes, which is essential for maintaining brand integrity and consumer trust.

Moreover, textile lab equipment includes apparatus for chemical testing, which assesses the effects of various substances on fabric properties. The American Society for Testing and Materials (ASTM) provides standardized procedures that equipment must adhere to, further emphasizing the importance of this equipment in developing high-quality textiles. Overall, the integration of advanced textile lab equipment is essential not just for compliance but also for innovation in textile product development.

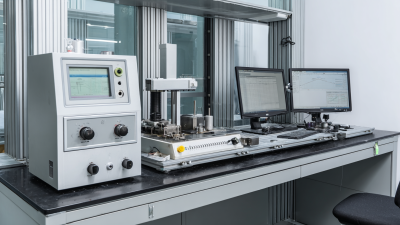

Textile lab equipment plays a crucial role in ensuring the quality and performance of textile materials. Various types of equipment are employed during the testing processes, each serving specific functions that help assess the properties of fabrics and fibers. Among the essential tools, fabric testing machines evaluate aspects such as tensile strength, elongation, and tearing resistance. These machines enable manufacturers and researchers to determine how materials will react under different conditions and stresses.

Another important category of textile lab equipment includes color and dye testing tools. These devices assess colorfastness, shade matching, and light stability, which are critical for maintaining product quality. Additionally, instruments for determining the physical properties of textiles—such as the thickness, weight, and layering of fabrics—contribute significantly to the understanding of their performance in various applications. Proper use of this equipment ensures that the textile products meet industry standards and consumer expectations, ultimately enhancing safety and satisfaction in the market.

Textile testing plays a crucial role in quality control and assurance within the textile industry. According to a report from the International Journal of Textile and Apparel, approximately 70% of consumer complaints stem from product performance failures. This underscores the necessity for rigorous testing protocols that ensure textiles meet the required standards for durability, safety, and functionality. By employing various textile lab equipment, such as tensile strength testers and colorfastness apparatus, manufacturers can assess the properties of fabrics, ensuring that they fulfill consumer expectations and regulatory requirements.

Moreover, the importance of textile testing extends beyond meeting immediate quality standards; it contributes to the overall sustainability of the industry. A study conducted by the Textile Research Journal indicates that effective testing can lead to a reduction in waste generation by as much as 40%, as defects are identified early in the production process. Implementing comprehensive testing procedures allows producers to not only minimize costs associated with returns and rework but also supports a commitment to sustainability by ensuring that only high-quality materials are used in the final products. Such practices help build consumer trust and foster loyalty, which is increasingly vital in a competitive market.

| Test Type | Test Equipment | Purpose | Importance in Quality Control |

|---|---|---|---|

| Tensile Strength Test | Universal Testing Machine | Measure the strength and elongation of the fabric. | Ensures that materials meet the necessary endurance standards. |

| Colorfastness Test | Colorfastness Tester | Assesses the ability of a fabric to retain color. | Verification of longevity of color under wash conditions. |

| Moisture Content Test | Moisture Analyzer | Determines the moisture level in fabrics. | Affects fabric weight and performance attributes. |

| Pilling Resistance Test | Pilling Tester | Evaluates fabric's tendency to form pills. | Ensures aesthetic and functional quality of textiles. |

| Abrasion Resistance Test | Abrasion Tester | Measures the durability of fabric under friction. | Helps in evaluating longevity and wearability of fabrics. |

Innovations in textile lab technology have transformed the way materials are tested and evaluated, enhancing the efficiency and accuracy of textile analysis. Advanced instruments are now capable of providing real-time data, allowing for quicker decision-making in the production process. For instance, developments in digital imaging and spectroscopy enable more precise examinations of fabric properties, including colorfastness, tensile strength, and durability. These breakthroughs not only streamline the testing process but also contribute to a more sustainable approach by reducing waste and the need for extensive manual testing.

Moreover, the integration of automation and artificial intelligence in textile laboratories has revolutionized traditional testing methods. Automated systems can conduct multiple tests simultaneously, minimizing human error and increasing throughput. Machine learning algorithms analyze vast amounts of data to predict material behavior under various conditions, catering to the demand for high-performance textiles. This synergy of technology fosters a deeper understanding of material characteristics, providing manufacturers with the tools necessary to innovate and enhance product quality. The continual advancements in textile lab technology underscore the industry's commitment to fostering innovation while meeting the evolving needs of consumers and the market.

Textile testing is essential for ensuring the quality and performance of fabrics. However, the process comes with a variety of challenges, particularly concerning equipment maintenance. Regular upkeep of textile lab equipment is crucial to maintaining accuracy in testing results. Equipment that is not properly maintained can lead to erroneous measurements, which can affect product quality and ultimately impact consumer safety. Therefore, laboratories must implement rigorous maintenance schedules to keep their equipment in optimal condition.

Additionally, the rapid advancements in textile technology present ongoing challenges for testing facilities. As new materials emerge, existing testing equipment may become obsolete or inadequate for assessing the properties of these innovative textiles. Laboratorians are often faced with the dilemma of whether to upgrade their equipment or adapt their testing methods to accommodate new textiles. Furthermore, the need for skilled technicians who can operate and maintain sophisticated equipment adds another layer of complexity to textile testing, making it imperative for organizations to invest in training and continuous education.