Home

Home

In the world of material testing, few tools are as crucial as the Tensile Strength Machine. This machine plays a vital role in understanding how materials withstand tension. As Dr. Emily Hart, a leading expert in material science, states, "The Tensile Strength Machine reveals the hidden strengths and weaknesses of materials." Her words highlight the importance of this technology in various industries.

Companies rely on Tensile Strength Machines to ensure product safety and quality. From aerospace components to medical devices, these machines test materials rigorously. They provide data that can guide improvements and innovations. However, it's important to understand that not all machines are created equal. Some may offer limited capabilities, which can lead to inaccurate results. This gap in performance can seriously impact industries that require precise measurements.

The market offers numerous options for Tensile Strength Machines. Each comes with unique features that cater to different needs. Yet, potential buyers must reflect on their specific requirements. Investing in the right machine can lead to significant advancements, but choosing poorly can result in costly mistakes. Thus, understanding these machines is paramount for anyone involved in materials testing.

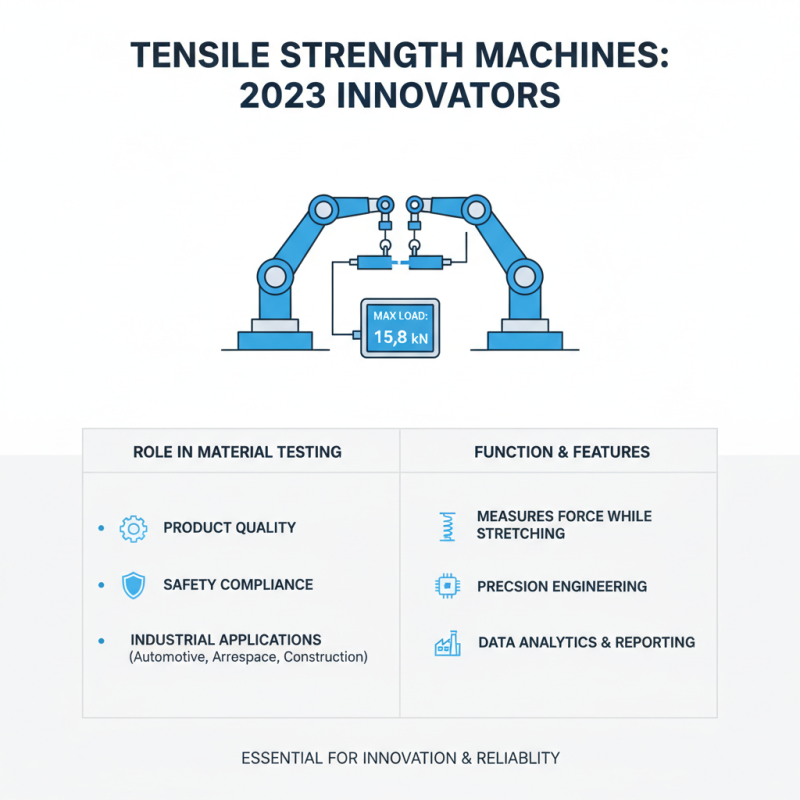

Tensile strength machines play a crucial role in material testing across various industries. In 2023, numerous machines stand out for their innovative features and precision. These machines measure how much force a material can withstand while being stretched. This capability is essential for ensuring product quality and safety.

One notable feature of modern tensile strength machines is their advanced data analysis capabilities. They can generate detailed reports, showing stress-strain curves and other important metrics. However, not all machines deliver the same level of accuracy. Some might struggle with calibration, leading to inconsistent results. Potential buyers should seek machines that offer easy calibration procedures.

Another aspect to consider is user interface. A machine may boast high functionality but may be difficult to operate. Complicated controls can lead to user errors. Training may be needed for effective usage, which adds extra cost. It’s essential to strike a balance between functionality and ease of use. Ultimately, selecting the right tensile strength machine involves thorough research and consideration of unique testing requirements.

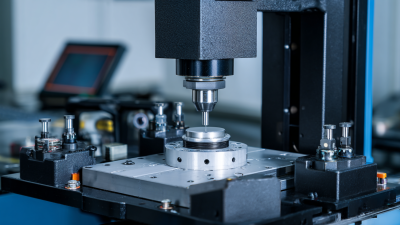

Tensile strength is a critical property of materials. It measures how much force a material can withstand while being stretched. Understanding this concept is vital in engineering, construction, and manufacturing. The measurement of tensile strength involves using specialized machines that apply a load to sample materials until they break. These machines provide essential data on the material's durability.

The testing process typically involves a standard sample shape, often a dog-bone shape. Measurement techniques vary, but they often include a gradual increase in tension. Observations are made until the material exhibits necking or breaks. Accurate readings can inform decisions on material selection for specific applications. Yet, not all testing methods are perfect; variations can lead to inconsistent results.

Tensile strength also reveals important insights into the elasticity and plasticity of materials. A balance exists between strength and ductility. While some materials are strong, they may be brittle. Others may deform under stress, losing their shape. Recognizing these traits can lead to better engineering practices. However, challenges remain, like variations in environmental conditions affecting tests.

Tensile strength machines play a crucial role in the manufacturing industry. They accurately measure the strength of materials, helping manufacturers ensure quality. By testing different materials, these machines identify weaknesses. This prevents costly failures in production.

In industries such as aerospace and automotive, the need for reliability is paramount. A slight miscalculation can lead to severe consequences. Tensile strength testing provides manufacturers with data to improve material selection and design. It allows for better performance and safety in end products.

However, not all manufacturers utilize these machines effectively. Some overlook the importance of regular maintenance. Without proper care, results may be unreliable. This can lead to using subpar materials. Continuous testing and improvement are essential. Ignoring this may hinder progress in manufacturing innovation.

When comparing tensile strength machines, performance and features are key. Many models offer advanced capabilities, but not all are suitable for every application. Some machines excel in precision, while others prioritize speed. It’s essential to choose based on specific needs.

Each model has its unique strengths and weaknesses. For instance, some machines are user-friendly but might lack advanced features. Conversely, others offer sophisticated technology but can be challenging to operate. Different materials may also impact machine performance, making it important to test them under real-world conditions.

Many users find it hard to decide. They often overlook maintenance needs. This oversight can lead to decreased accuracy over time. Furthermore, not every machine is designed for heavy loads. Considering these factors can greatly influence long-term satisfaction and effectiveness.

The world of tensile strength testing is witnessing rapid changes. High-tech machines now have advanced sensors that provide real-time data. This shift allows for more accurate measurements and faster results. Innovations in software also play a crucial role. Enhanced data analysis tools help engineers make informed decisions more efficiently.

Researchers are increasingly focused on automation. Intelligent systems can now perform tests with minimal human intervention. This trend raises questions about reliability and understanding of results. Could users become overly reliant on machines? A delicate balance between technology and human expertise is essential. Additionally, some machines may struggle to adapt to unconventional materials. This limitation can hinder progress.

Another area of exploration is the integration of artificial intelligence. AI can predict material failure points based on thousands of test samples. This approach offers exciting possibilities, yet it requires careful validation. Understanding the nuances of AI-generated data is vital. As innovations unfold, the industry must reflect on the implications. Testing remains a fundamental part of material science. Embracing technology while respecting traditional methods is key.