EN 388:2016+A1:2018 Gloves are resistant to abrasion, cutting and tearing

2025-04-30

European standard EN 388:2016+A1:2018 - "Protective gloves against mechanical risks" has now been published to replace EN 388:2003. General purpose protective gloves account for the largest market share of all personal protective equipment (PPE) sold and protect the wearer from a wide range of hazards. To help the wearer choose the right gloves, several European safety standards (including EN 388:2016+A1:2018) have been developed, allowing the definition of protection levels for different risks. These defined protection levels allow the selection of the right gloves based on the hazards and risks identified for a specific work activity.

The EN 388:2016+A1:2018 standard is intended to be used in conjunction with EN 420:2003+A1:2009 - "Protective gloves". General requirements and test methods are intended to ensure that the gloves themselves do not cause harm to the wearer and are comfortable to wear. EN 420 is currently under revision and once the standard is updated it will become EN ISO 21420.

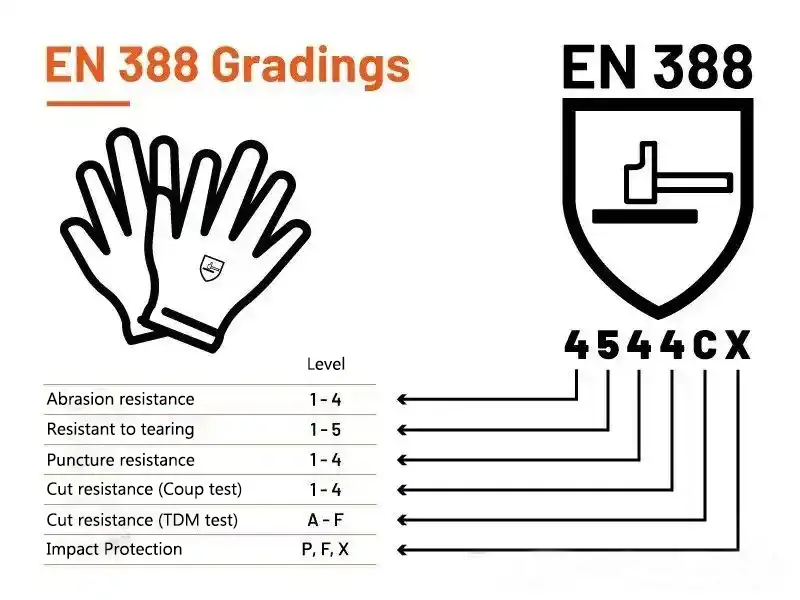

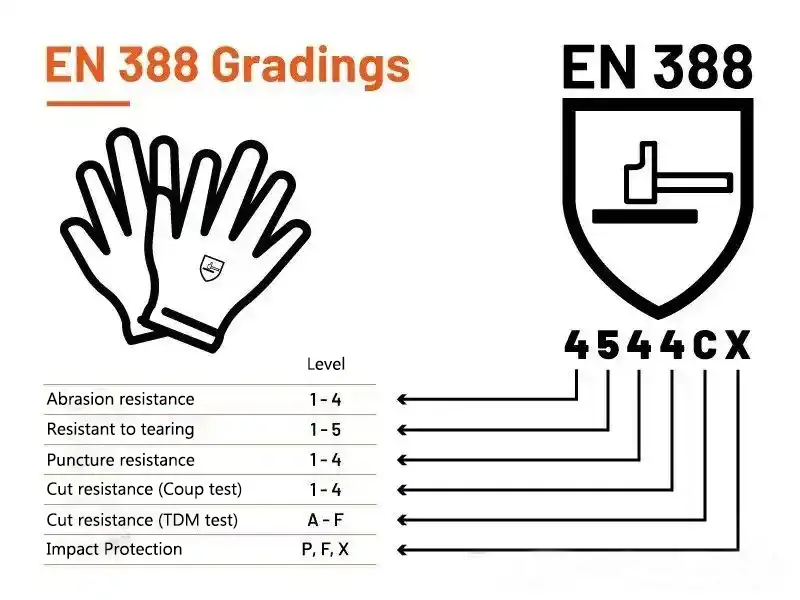

EN 388:2016+A1:2018 specifies requirements, test methods, marking and information for protective gloves against mechanical risks such as abrasion, blade cuts, tears, punctures and (if applicable) impact. The test procedure includes separate tests for each of these characteristics. The performance level is determined based on each test result - the higher the number or ascending letter, the higher the protection level. The results are displayed using pictograms (Figure 1) that provide a clear understanding of the performance of the glove.

EN 388:2016+A1:2018 standard test items:

1. Abrasion resistance:

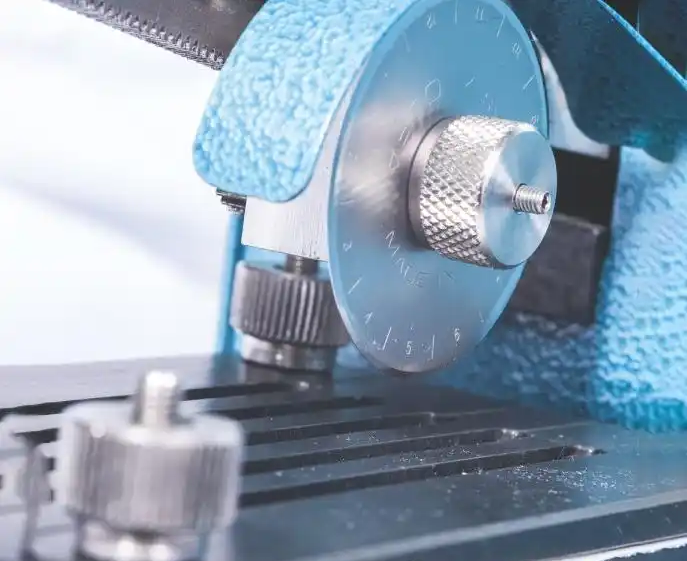

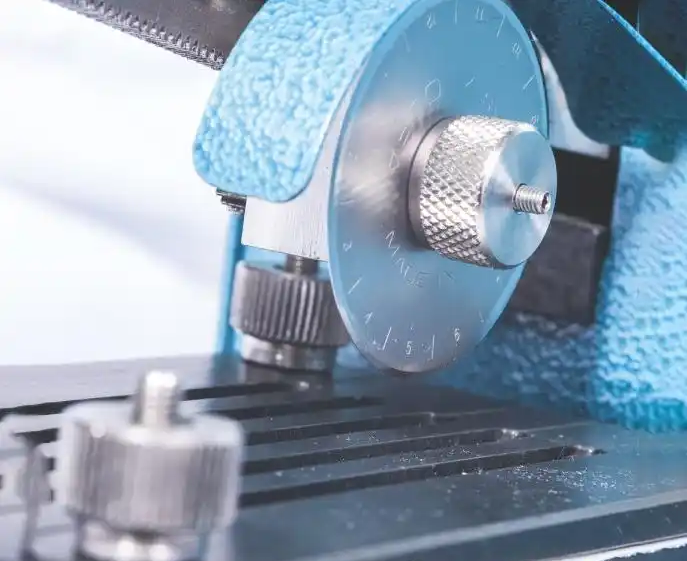

Compared with EN 388:2003, the abrasion resistance method has a significant technical change in the choice of sandpaper. The resistance test is carried out on a Martindale Abrasion Machine, where a material sample (cut from the palm of the glove) is mounted on a friction head of fixed size and weight. The abrasion head is then moved in an elliptical motion on a table covered with 180 grit abrasive material (unlike the 2003 version, where 100 grit was specified).

Four samples of the material are tested and the test result is the number of cycles required to wear through ("punch") the material. For knitted gloves, the test is completed when one thread breaks, or for woven fabrics, when two separate threads break. The performance level of a single material is determined by the lowest result of the four tests. For multi-layer materials (where the specimen is made of multiple unbonded layers), each layer is tested separately and the performance level is based on the sum of the number of cycles.

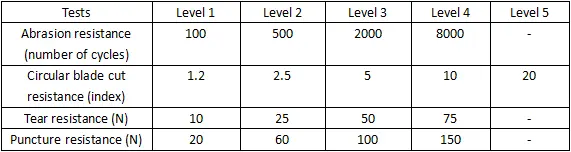

Four performance levels are defined in EN 388, ranging from "Level 1" (equivalent to perforation between 100 and 499 cycles) to "Level 4" where perforation does not occur before 8000 cycles, as shown in Table 1.

2. Round and straight blade cut resistance:

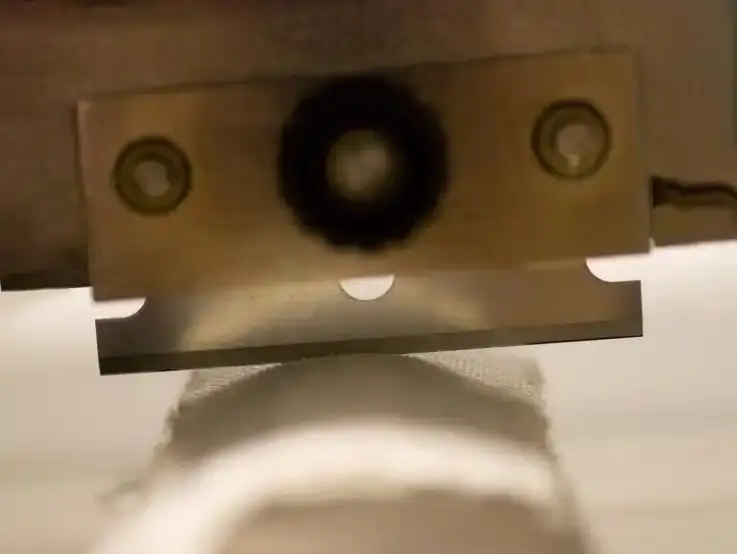

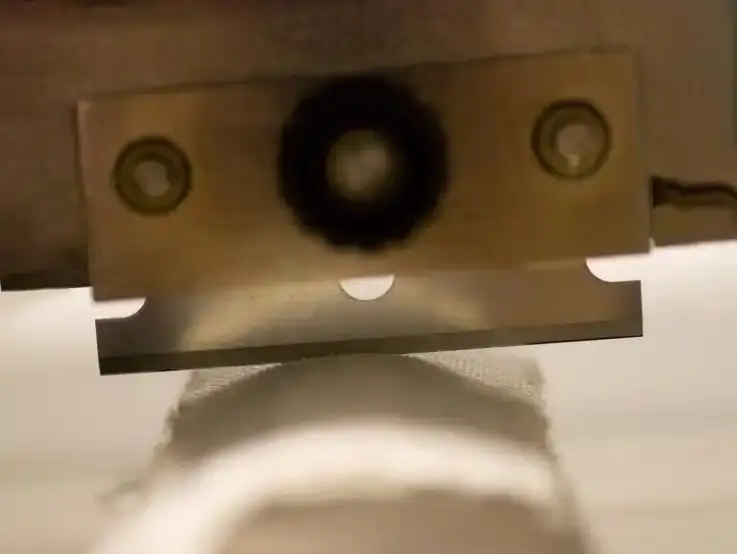

The 2003 version of the standard contains a test procedure for the round blade cut test, also known as the "coupe test", and also references the straight blade cut test for materials with higher cut resistance. The round blade cut test is conducted on a round blade cut resistance tester consisting of counter-rotating blades (under a standard 5N contact force) moving back and forth across a fixed plane of the test material for a stroke length (Figure 2),

In the case of multiple layers of material, the layers are assembled and tested as in a glove. The test stops when blade cut-through is detected (by electrical contact with the underlying surface) or when 60 cycles are reached, and the number of strokes completed by the blade is recorded. To account for the sharpness of the blade, a standard canvas control material is tested before and after the test specimen. The "blade cut index value" is calculated based on the number of cycles required to cut the specimen and the average number of cycles required to cut the control material.

A specimen is taken from two separate gloves and five test cuts are made on each glove, which allows for any differences between gloves. The average blade cut index is calculated for each test specimen. The performance rating is based on the lower average blade cut index of the two specimens and ranges from Class 1, with a cut resistance index greater than 1.2, to Class 5, with a cut resistance index greater than 20, as shown in Table 1. It is also worth noting that EN388:2016+A1:2018 has made several improvements to the control of blades.

The use of a circular blade cut test for composite fiber-based materials (including ** technical aramid) and other specialized materials has its limitations. For all of these products designed to achieve high levels of cut resistance, blunting of the blade during extended testing means that the results of the second control sample may be meaningless. Glass fibers and abrasive surfaces may also produce different results between individual cuts due to local variations in the specimen. Steel fibers may make electrical contact with the specimen holder, giving a false reading indicating the point of cut-through.

The alternative straight blade cut test method given in ISO 13997:1999 - "Protective clothing - Mechanical properties - Determination of resistance to cuts by sharp objects" is fully covered by EN 388:2016+A1:2018. If the number of cycles to cut the reference material increases more than three times during any single circular blade cut test, the ISO 13997:1999 cut resistance method becomes the reference test method for evaluating cut protection. This test uses a straight blade to stroke across the sample until cut-through occurs (Figure 3) and measures the contact load applied to the blade to cut-through over a stroke length of 20 mm. Since the blade moves across the sample only once and each blade is used only once, the problem of blade dulling from repeated cycles is eliminated. Multiple tests were performed with different contact loads applied to the blade. Force and cut length were plotted on a scatter plot and a trend line was generated.

Home

Home