0102030405

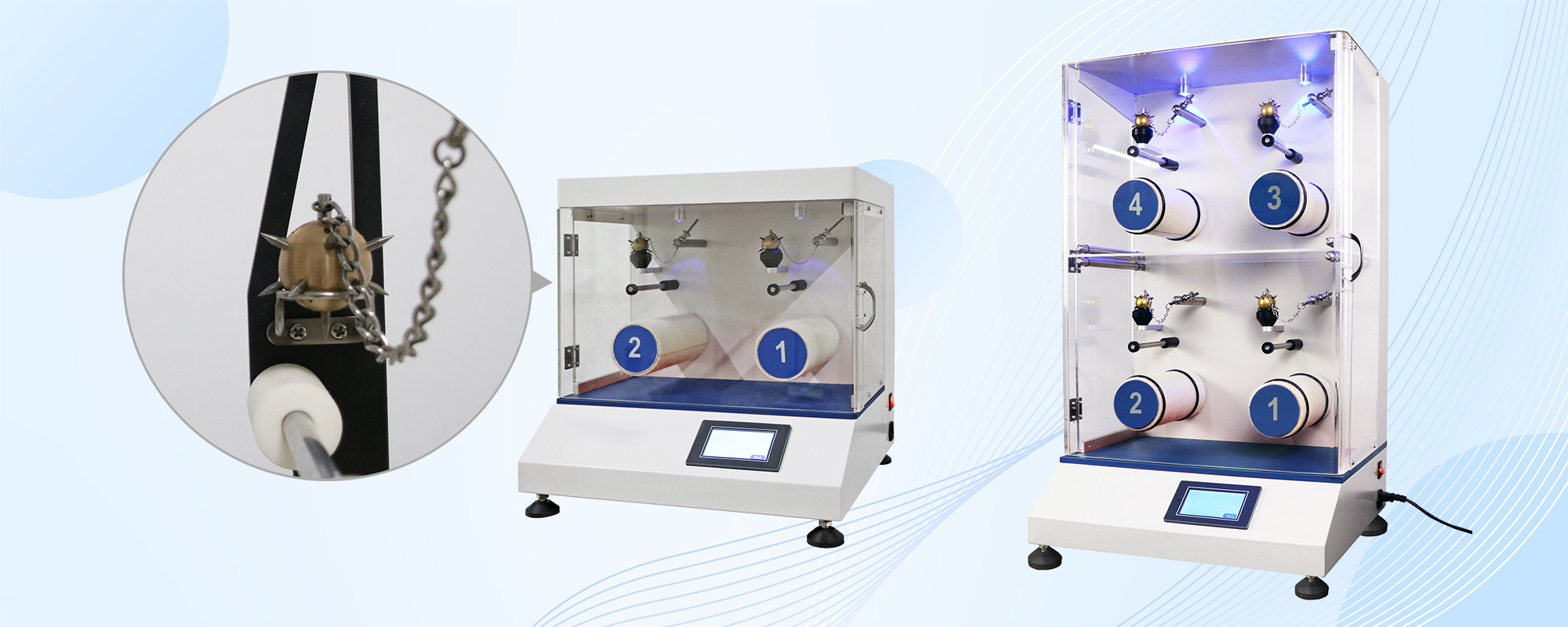

Fabric Ici Mace Snag Tester

2025-07-18

Fabric Ici Mace Snag Testing is an important method for assessing the snag resistance of knitted fabrics and some woven fabrics. It is widely used in quality control, product development, and standard compliance testing in the textile industry. The following is an introduction to its working principle, structural components, technical parameters, operating methods, maintenance, and other aspects:

1. Core standards:

GB/T 11047-2008 ‘Textiles — Evaluation of fabric snagging properties — Hammer test method’

ISO 13935-1:2019 ‘Textiles — Determination of fabric snagging properties — Part 1: Hammer test method’

ASTM D3939 (American Society for Testing and Materials standard), etc.

2. Applicable fabrics

Mainly applicable to knitted fabrics (such as underwear, sweaters, sportswear fabrics, etc.), it can also be used for some woven fabrics that are prone to snagging (such as lightweight synthetic fabrics). The focus is on evaluating the fabric's resistance to friction and snagging during daily use, which can cause fibres to be pulled out and form loops or pilling.

3.Working Principle: A package of beads with a known weight is placed into the knitted fabric sample, which is then inserted into a test drum equipped with needle rods. The test drum rotates at a specified speed, causing the knitted fabric and bead pillows to tumble and friction within the drum, simulating the snagging conditions the fabric may encounter during actual use. After a predetermined number of revolutions, the test is stopped, the sample is removed, and the fabric's snagging grade is evaluated according to relevant standards.

4. Structural Components

Drive system: motor and transmission device to control the rotation of the specimen cylinder.

Sample cylinder: Smooth-surfaced, removable cylindrical cylinder for wrapping and fixing the fabric sample to be tested. The standard diameter is usually 92±1mm.

Bead Pillow (Staple Hammer/Puncture Roller): The core component. Usually a cylinder with stainless steel pins or nails of a specific specification (e.g. diameter, length, number, arrangement) regularly set on the surface. Its weight is an important parameter for testing (e.g. 2.5kg is a common standard requirement). Some instruments may be equipped with bead pillows of different sizes.

Weights (optional): used to accurately regulate the total pressure applied to the bead cushion (weight of the cushion + additional weights).

Counter: Records the number of revolutions (RPM) of the specimen cylinder.

Protective cover: prevents the bead cushion from accidentally flying or spilling of sample fragments during the test for safety.

Base and Frame: Supports the entire structure of the instrument.

5. Technical Specifications

Test Speed: Typically 20±3 rpm.

Power Supply Voltage: AC 220V ±10%, power approximately 60W.

Dimensions: Vary by model, e.g., 470×420×390 mm or 47×38×38 cm, etc.

6. Operating Procedures

Preparation: Select appropriate knitted fabric samples, ensure the sample dimensions meet requirements, and prepare bead pillows of qualified weight. Connect the power supply and check if the instrument is operating normally.

Sample Installation: Place the bead pillow into the knitted fabric sample, then secure the sample with the bead pillow in the sample clamp, and insert the sample clamp into the test drum.

Parameter Settings: Set the test drum's rotation speed, RPM, and other parameters according to the test standards and requirements.

Start Test: Activate the instrument, and the test drum begins rotating. The knitted fabric and bead pillow roll and friction within the drum to conduct the pilling test.

Test Completion: When the counter displays the predetermined rotation count, the instrument automatically stops. Remove the sample and evaluate its pilling grade according to relevant standards.

7. Maintenance and Care

Regular Cleaning: Regularly clean the test drum, needle rod, and fabric debris, dust, and other contaminants from the needles to maintain the cleanliness of the instrument’s interior and prevent interference with test results.

Inspect Components: Regularly inspect components such as the needle rod, needles, and sample clamps for damage, deformation, or loosening. If any issues are found, promptly replace or repair them to ensure the instrument operates normally.

Instrument Calibration: Calibrate the instrument regularly in accordance with the manufacturer's recommendations and relevant standards to ensure the accuracy and reliability of test results.

Proper Storage: When not in use, store the instrument in a dry, well-ventilated environment to prevent moisture, rust, or other damage.

Home

Home