0102030405

How Are Shoes and Leather Products Tested for Flexibility Resistance

2025-09-04

In the production and quality control of leather products, flex resistance (folding resistance) testers play a crucial role. Whether it be leather shoes, bags, or clothing, the durability and flexibility of leather directly affect the product's lifespan and the consumer experience.

1. What is a leather flexing (folding) tester?

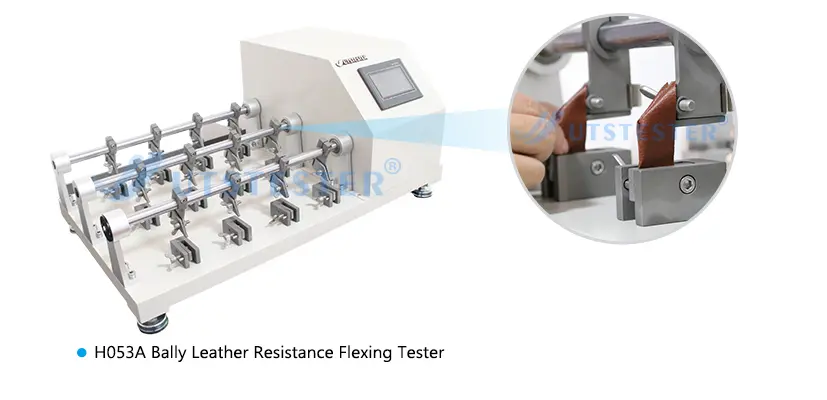

A leather flexing tester is a device specifically designed to test the load capacity of leather materials during repeated bending or folding. It simulates the pressure and friction that leather is subjected to during daily use, assessing its durability and performance. The test results provide detailed data through indicators such as the number of breaks and the degree of wear, thereby assisting in improving product design and material selection.

2. Principle of Flexibility Testing

Flexibility testing typically employs specialized mechanical devices to conduct simulated experiments under strictly defined force, frequency, and cycle conditions. The testing equipment secures the leather sample in a testing fixture and then repeatedly bends the sample using the mechanical device. The primary purpose of these tests is to assess changes in appearance, physical properties, and structural integrity of the leather after prolonged repeated use. By comparing the appearance and mechanical properties before and after testing, it is possible to clearly determine whether the product can withstand daily wear and tear.

3. Why is leather flex resistance testing so important?

(1) Ensuring product quality and reliability

Flex resistance testing ensures that leather products meet quality standards in actual use. For example, in the footwear industry, the flex resistance of a pair of shoes directly affects wearing comfort and safety. If the leather material wears out or becomes damaged prematurely, it may cause discomfort or even injury to users during daily walking.

(2) Enhancing Market Competitiveness

In the highly competitive leather market, product quality is key to gaining consumer trust. By conducting comprehensive flex resistance testing, manufacturers can produce higher-quality products, thereby enhancing brand image and market share.

(3) Compliance with Industry Standards and Regulations

Many countries and regions have strict standards and requirements for leather product quality. Conducting flex resistance testing helps manufacturers meet these regulatory requirements and comply with market access rules.

4. Leather Flexibility Test Method and Steps:

(1) Select appropriate testing equipment

Depending on different testing requirements, various testing equipment can be selected. There are multiple automated and semi-automated testing instruments available for selection.

(2) Prepare samples

Generally, testing should use multiple samples to ensure the reliability and validity of the data.

(3) Set Test Parameters

Before conducting the test, appropriate test parameters must be set based on the characteristics of the product, including the number of bends, frequency, and testing force.

(4) Conduct the Test

Secure the prepared samples in the flex resistance tester, then start the equipment to conduct the test. During the test, observe any changes in the samples and record whether they meet or fail to meet the standards.

(5) Data analysis and evaluation

After the test, the obtained data should be analyzed in detail to assess whether the samples meet the pre-set quality standards. If the samples fail the test, adjustments should be made to the raw materials or production process.

Home

Home