0102030405

How Are Shoes and Leather Products Tested for Wear Resistance

2025-08-30

The wear resistance of leather is the property of leather to resist wear. The wear of leather is an important cause of leather damage.The leather wear resistance test is extremely important for evaluating the wear fastness of leather.

Leather testing method:

1. Flat abrasion method

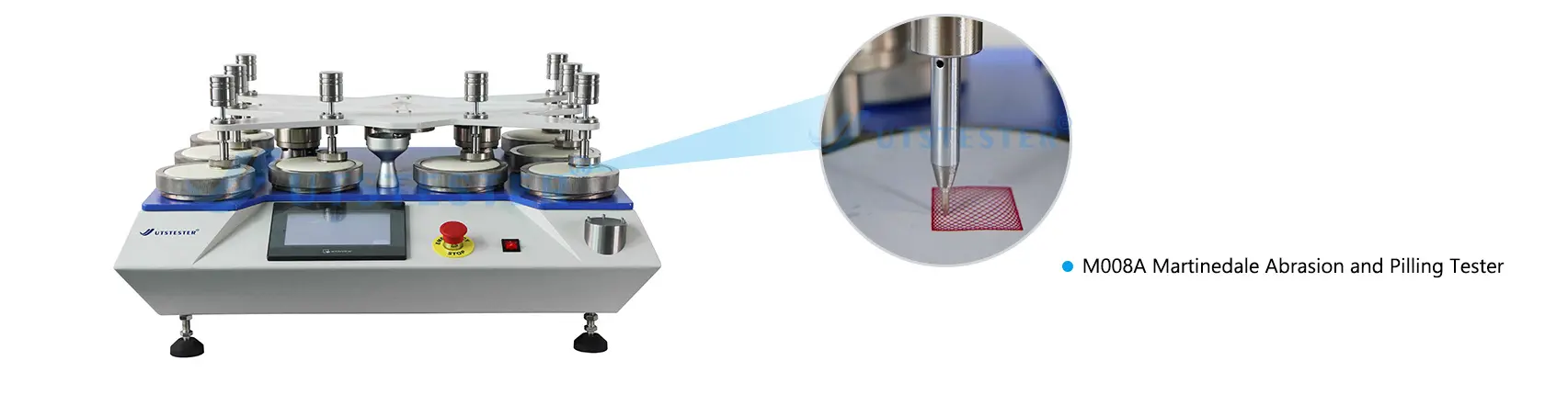

(1) Test instrument: There are many types of fabric flat abrasion testers. The most commonly used one in the testing industry is the Martindale Abrasion Tester. Therefore, the flat abrasion method is often called the MARTINDALE friction tester method.

(2) Test principle: The circular sample installed in the Martindale abrasion tester sample fixture is rubbed against the abrasive (i.e., standard fabric) in the plane motion of the Lissajous figure under a specified load. The sample fixture can rotate freely around its axis perpendicular to the horizontal plane. The wear resistance of the leather is determined based on the total number of friction times the sample is damaged.

(3) Test method: During the test, a test specimen of a certain size is brought into contact with a standard abrasive under a specified pressure, and the specimen is moved relative to the abrasive in a Lissajous trajectory, so that the test specimen is subjected to uniform wear in multiple directions.

2. Taber wear test

(1) Test instrument: TABER Wear Tester

(2) Test principle: Pre-grinding revolutions, the sample to be tested is placed on the horizontal platform of the TABER wear tester and rotated, two grinding wheels are given a specific pressure to press on the test piece, the axis of the grinding wheel is parallel to the horizontal plane, one grinding wheel faces outward and the other faces inward, and all changes of the test piece are recorded within a certain period of time.

(3)Test method: Use a cutter to cut a sample of standard size. Then stick a hard sticker of the same size on the back of the sample. Place the center hole of the sample on the rubber pad of the screw, put on the gasket, and fix the sample with a compression nut. Then put on the fixing ring and tighten the fixing ring screw with a wrench. Install two grinding wheels on the support arm. Each grinding wheel applies a force of 250±10g to the test sample, ensuring that the side with the label faces outward, so that the weight of the grinding wheel is 500g. Connect the vacuum cleaner, connect the vacuum cleaner's dust pipe to the connector on the left side of the machine, and start the vacuum cleaner. Set the test times according to the standard and set the rotation speed to 72 revolutions. Then press the start button, start the instrument with a rotation speed of 60±5 times/min, rotate horizontally, and test according to the required times. During the test, use a brush to remove the attached materials on the surface of the sample, observe the wear of the test, grind the leather to the specified end point, and record the final number of revolutions.

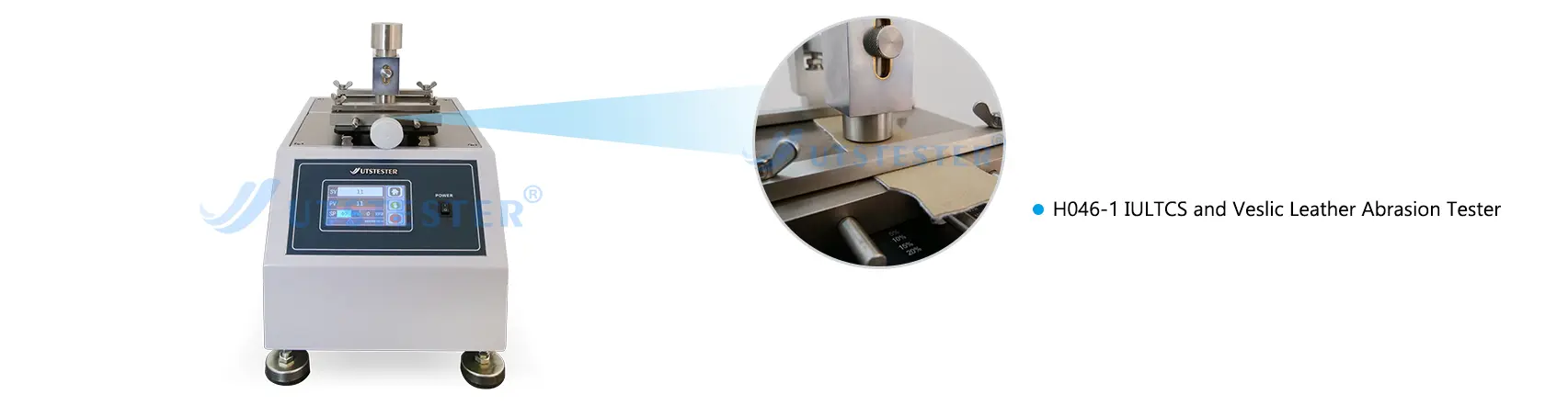

3. IULTCS Veslic Leather Friction Test Method

(1) Test instrument: IULTCS Veslic Leather Friction Tester

(2) Test principle: IULTCS Veslic Leather Friction Tester, also known as Leather Friction Decolorization Tester, is suitable for color fastness testing of leather, plastic, etc. It determines the friction decolorization level of the sample by repeatedly rubbing the sample. It can be used for dry and wet friction tests.

(3) Test method: The surface of the dye sample is repeatedly rubbed with white wool felt under a certain pressure. After a certain number of tests, the color fastness is evaluated by observing the color change and fading of the sample and the color change of the white wool felt.

Home

Home