0102030405

Tensile strength machine function description

2025-06-27

Tensile machine is also known as Universal Material Testing Machine. Tensile machine is used for a variety of materials for instrumentation static load, tensile, compression, bending, shear, tearing, peeling and other mechanical properties of the mechanical properties of the test with the mechanical force of the test machine. Applicable to plastic plates, tubes, profiles, plastic film and rubber, wire and cable, steel, glass fibre and other materials, a variety of physical and mechanical properties of the test, then what are the main functions of the tensile strength machine?

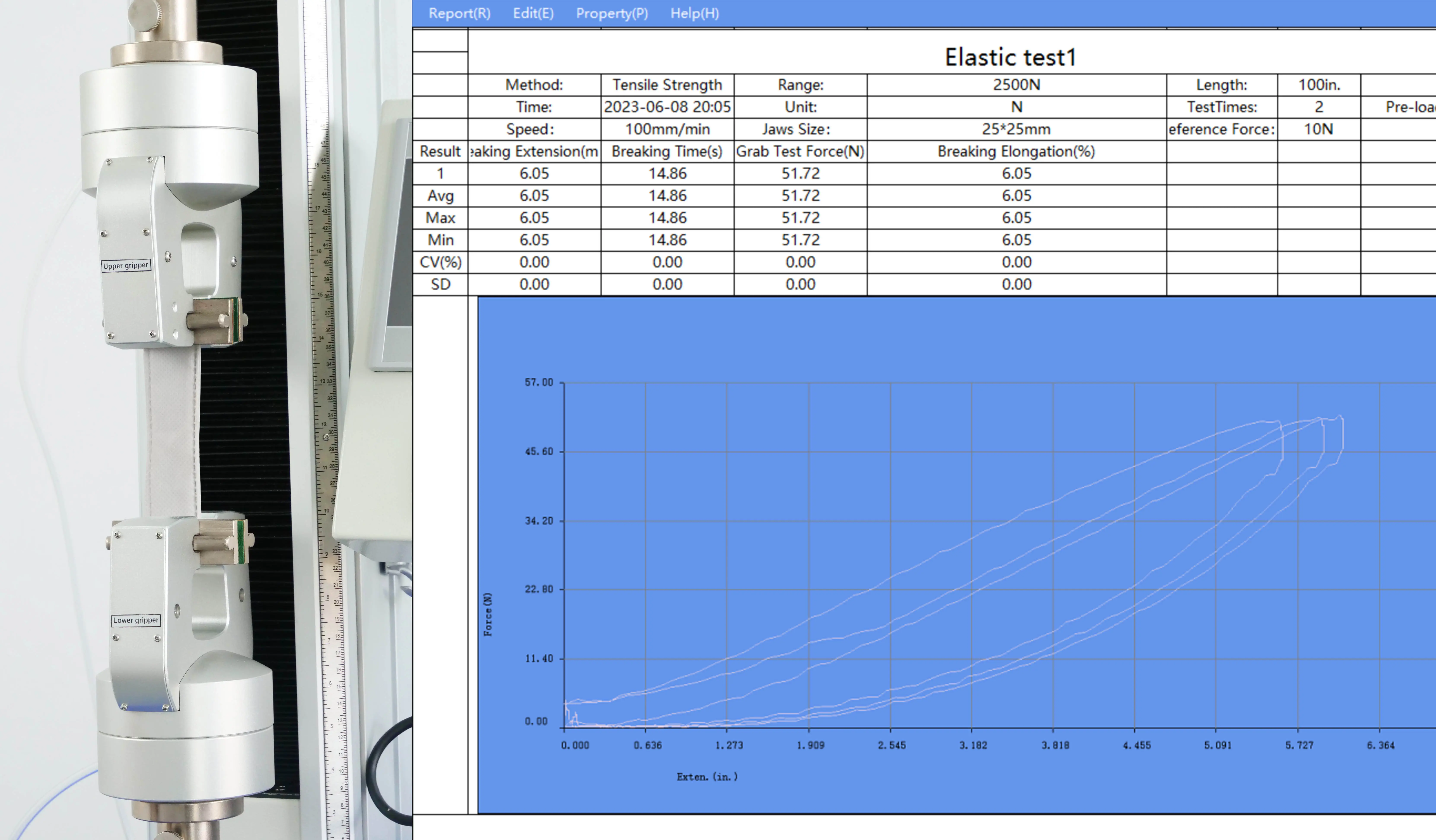

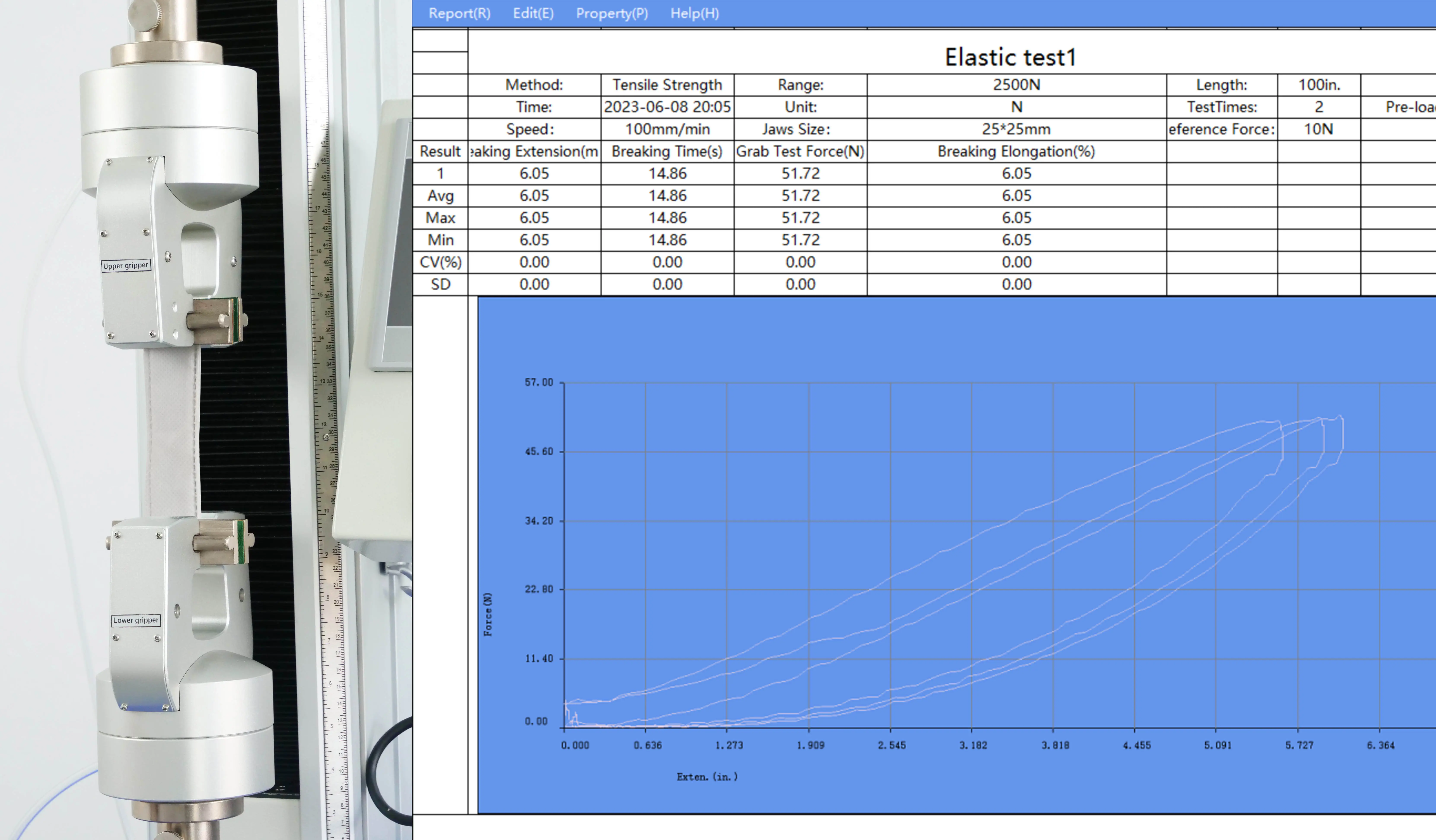

1、Control software: It can realise automatic acquisition of tensile strength, yield strength, breaking strength, modulus of elasticity, elongation and other test data, and open formula editing can automatically calculate the force, stress, displacement, deformation and other data results of any specified point in the test process. The control of the test process and data processing meets the requirements of the corresponding national standards for metallic and non-metallic materials.

2, control mode: fixed speed, positioning shift, fixed load, fixed load increment, fixed stress, fixed stress increment, fixed strain, fixed strain increment and other control modes can be selected;

3, automatic zero: after the start of the test, the measurement system is automatically adjusted to zero

4, automatic shift: according to the size of the load is automatically switched to the appropriate range, in order to ensure the accuracy of the corona data;

5, automatic disc: the test data and the test conditions are automatically stored in the disc to eliminate the risk of forgetting to save the disc. Eliminate data loss caused by forgetting to save

6, batch test: for the same parameters of the specimen, a setup can be completed after a batch of tests;

7, display mode: data and curve with the test process dynamic display;

8, curve traversal: after the completion of the test, the curve can be reanalysed, the mouse to find out the test curve at each point corresponding to the validity of the evidence;

9, the curve to choose: you can choose the stress-strain, force displacement, force time, displacement time and other curves to display. Displacement time and other curves to display and print

10, unit switching: force unit: (g, kg, N, 1b), stress unit: (kg/mm2, N/mm2, Mpa, 1bf/in2) displacement unit: (m, mm, in);

11, the test report: can be programmed in accordance with the user's requirements of the format of the test report and print, and can be exported to EXCEL files;

12, safety protection: exceeding a very large number of test reports can be programmed to print, and can export the EXCEL file; 12 Safety protection: over a large load of 2 ~ 10%, the automatic realization of safety protection;

13, can automatically detect and calculate the mechanical properties of the specimen index can also be manually intervene in the analysis process, according to the requirements of the relevant standards on the automatic analysis of the results of the corrections to improve the accuracy of the data.

Home

Home