Yarn hairiness: the invisible killer of textile quality? Definition, Effects and Testing Methods

2025-03-07

1.What is yarn hairiness

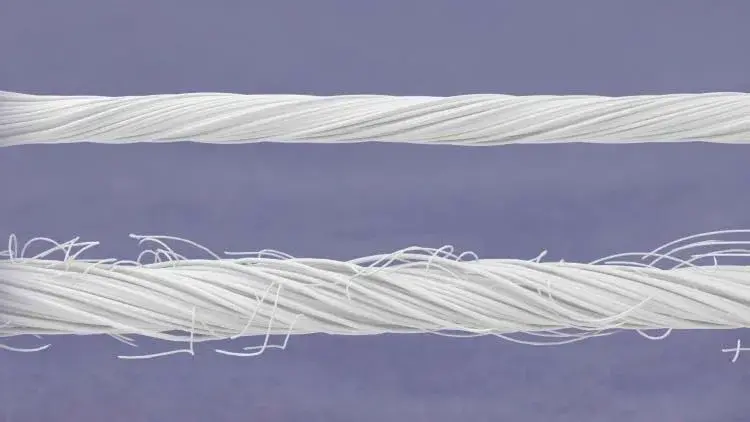

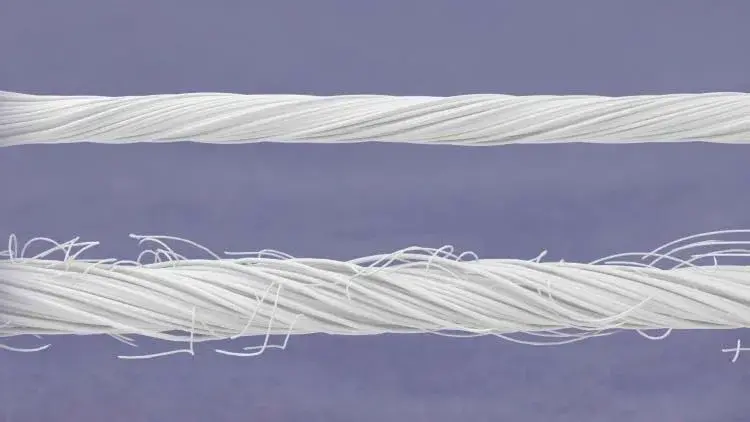

Yarn hairiness refers to the protruding or free portion of fibers present on the surface or ends of the yarn. These fibers are not fully integrated into the main body of the yarn, forming a structure similar to “hair”, which directly affects the quality of the yarn and the performance of the final fabric.

The hairiness index is usually used to characterize the amount of hairiness, hairiness index is defined as: in unit yarn length of one side of the yarn plane view of a side, more than a certain projection length (vertical distance) of the cumulative number of hair feathers, the unit of root/10m (the size of the index value is affected by the length of the test length and projection length and other factors).

2. How yarn hairiness affects fabrics

First of all, we have to understand that hairiness is the basic structure of yarn, which is unavoidable. Reasonable hairiness is acceptable, but what brings problems are those bad yarn hairiness, bad hairiness mainly has the following phenomena.

2.1 Excessive hairiness will lead to hairiness and pilling on the surface of the fabric, affecting the finish and color uniformity. In the dyeing process, hairiness is easy to appear at the color difference or uneven dyeing

2.2 Fabrics made from yarns with prominent hairiness may feel rough to the touch, reducing wearing comfort. For intimate apparel (e.g. underwear, T-shirts), hairiness may also cause itching sensation on the skin.

2.3 Hairiness is easily shed during friction, resulting in thinner yarns and reduced fabric strength. Dense areas of hairiness may become the starting point of abrasion, accelerating fabric damage.

2.4 In the weaving process, hairiness is easy to cause warp yarn breakage or loom downtime, affecting production efficiency. Hair feathers may also clog the nozzle of the air jet loom, increasing energy consumption.

3. Yarn hairiness detection methods

3.1 Optical projection method: Use hairiness detector to conduct high-speed camera on the yarn to count the number and length distribution of hairiness per unit length. Standard: ASTM D5647 (hairiness index test).

3.2 Capacitance method: Detect changes in yarn diameter through capacitance sensors, indirectly reflecting the hairiness density, suitable for online monitoring, but can not distinguish the length of hairiness.

3.3 Burning method: The yarn is burned and the hairiness content is calculated by the weight difference before and after burning (applicable to specific process verification).

3.4 Manual counting method: visually counting the hairiness of fixed length yarns under a microscope, low precision but low cost, suitable for laboratory analysis of small samples.

4.UTSTESTER equipment for detecting yarn hairiness

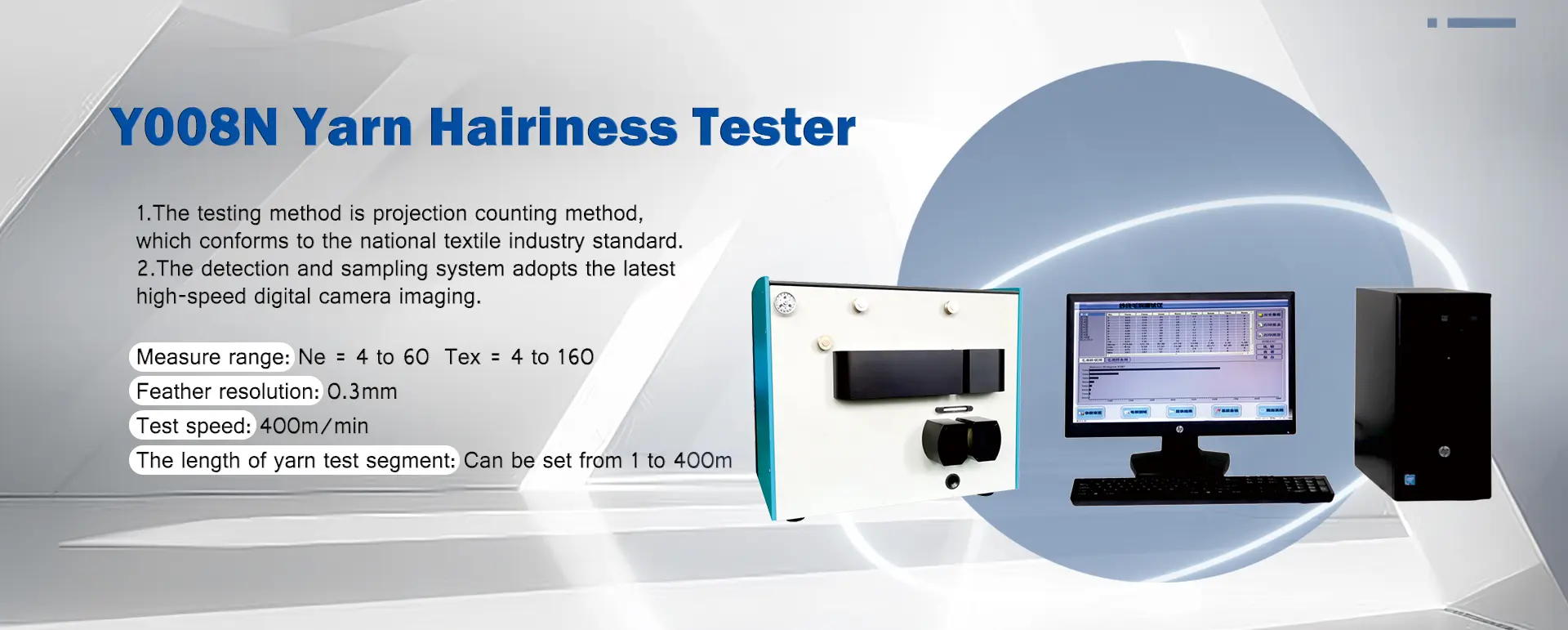

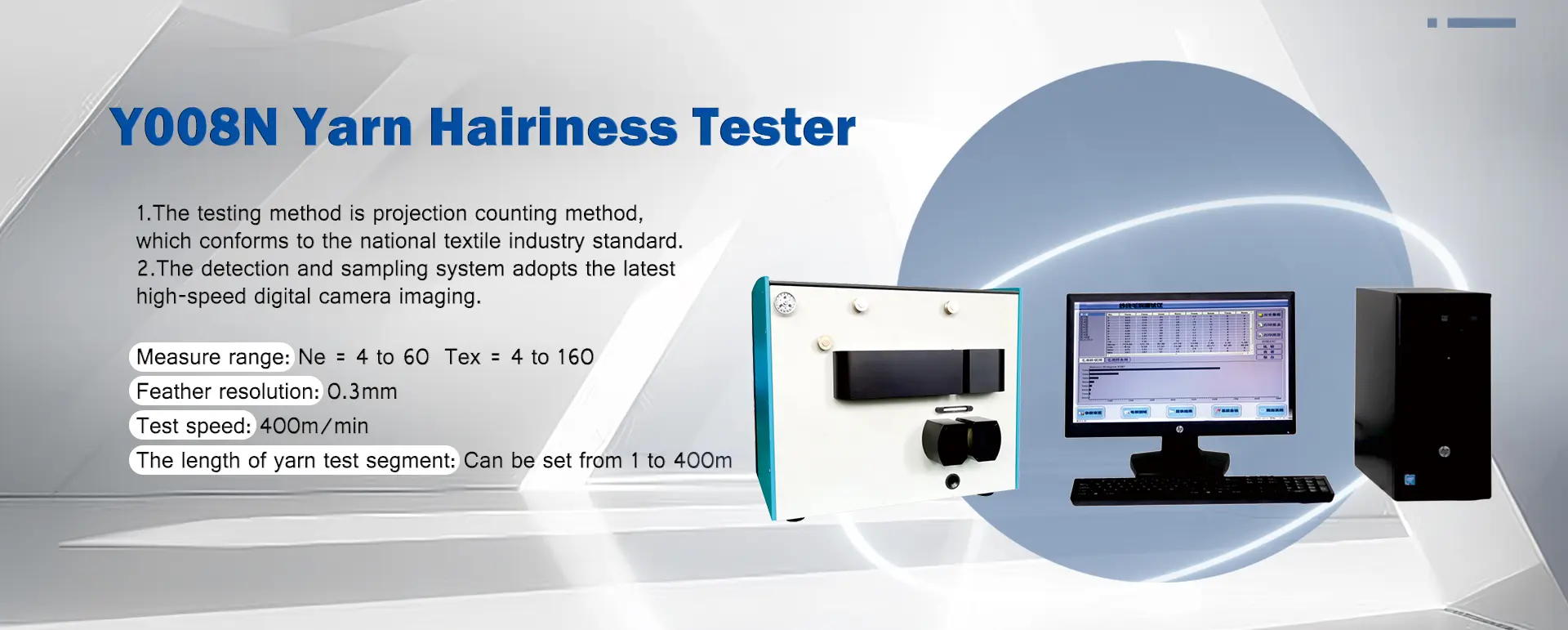

4.1 Y008N Yarn Hairiness Tester

Product Application:Yarn hairiness tester is used for measuring and analyzing yarn hairiness index, automatic testing and statistical analysis of length, quantity and distribution of hairiness.

Characteristics:A high-speed industrial camera (CCD) is used to photograph the hairiness at the frame level, and the results of the shooting data are processed to count the number of hairiness to generate the final number of hairiness. The imaging is clear, the test accuracy reaches micron level, and the repeatability is good. The product can actively detect the light intensity of the test and automatically adjust it to ensure the accuracy and consistency of each test data, and the long-term stability is greatly guaranteed.

4.2 Y010A-HD Full Automatic Yarn and Sliver Evenness Tester

Product Application:Y010A-HD evenness test and analyzer (hereinafter referred to as Y010A-HD evenness meter) is a high-speed and efficient evenness test and analysis instrument developed and produced by UTSTESTER. It is used to test and analyze the unevenness of yarn and assess the evenness of yarn. Yarn quality, guide yarn production.

Characteristics:It integrates capacitance, hairiness, and photoelectric sensors to simultaneously measure yarn backbone, hairiness index, diameter and other indicators, and provides graphics such as spectrum diagrams and variation-length curves.Fully automatic measurement, complete 20 tubes of spun yarn testing at one time. It can also be divided into two groups to complete two varieties of tests at one time.The expert analysis system can evaluate the yarn quality level and provide users with process and equipment failure analysis results. Advanced yarn hairiness index testing, in line with international standards.

4.3 Yarn Sliver and Roving Evenness Tester(With Hairiness Function)

Product Application:Y010E Yarn Sliver and Roving Evenness Tester is designed specially for test the evenness faults for spun yarn, roving, sliver.

Characteristics:Optional yarn hairiness index function. To test hairiness units only.

Home

Home