- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

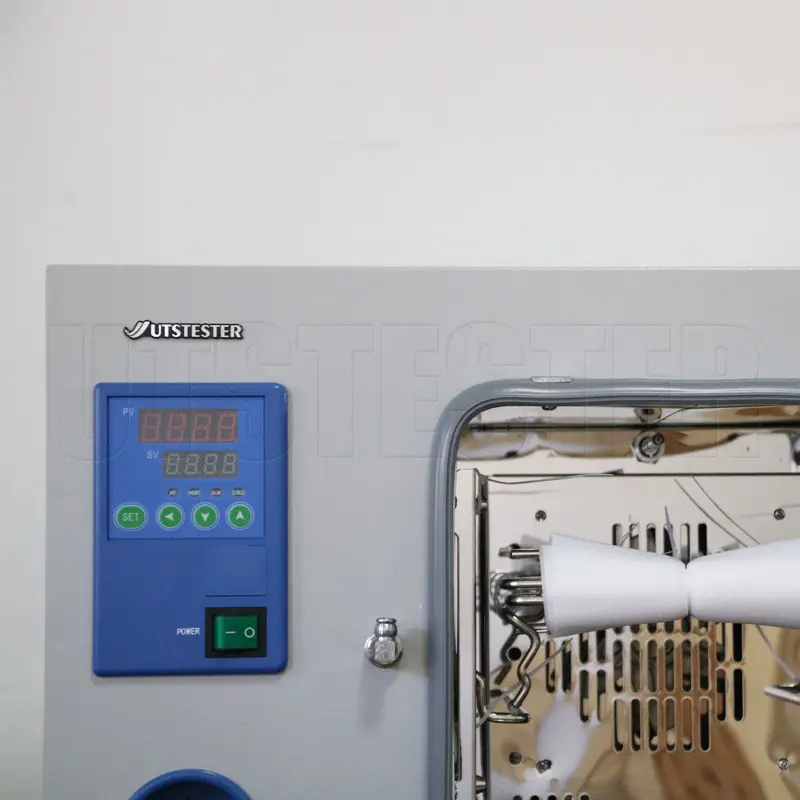

Drying Oven Hot Air Circulation Drying Machine

Overview

D010A Drying oven is used to dry, bake and preheat various materials or specimen by hot air circulation method to uniform the temperature distribution. Provided for desiccation, torrefaction, wax-melting and sterilization in mining enterprises, laboratories and scientific research institutes.

Application

Standards

Resistance to Perspiration: GB/ T 3922, AATCC 15, ISO105

Resistance to Sea Water: GB/ T5714, AATCC107, ISO105

Resistance to Water: GB/ T5713, AATCC106, ISO105

Assessment of migration of textile colours into polyvinyl chloride coatings: ISO105 X10

Key Parameters

| Model | D010A-30L | D010A-50L | D010A-80L | D010A-136L | D010A-220L | D010A-420L | D010A-620L |

| Input power | 850W | 1100W | 1550W | 2050W | 2450W | 3100W | 4000W |

| Volume | 30L | 50L | 80L | 136L | 220L | 420L | 620L |

| Inner size ( W*D*H) (mm) |

340 × 320 × 320 |

420 × 395 × 350 |

450 × 400 × 450 |

550 × 450 × 550 |

600 × 500 × 750 |

640 × 585 × 1355 |

840 × 600 × 1355 |

| Outside size ( W*D*H) (mm) |

620 × 440 × 490 |

720 × 530 × 520 | 740 × 530 × 630 | 840 × 580 × 730 | 880 × 630 × 930 | 780 × 750 × 1880 | 980 × 800 × 1880 |

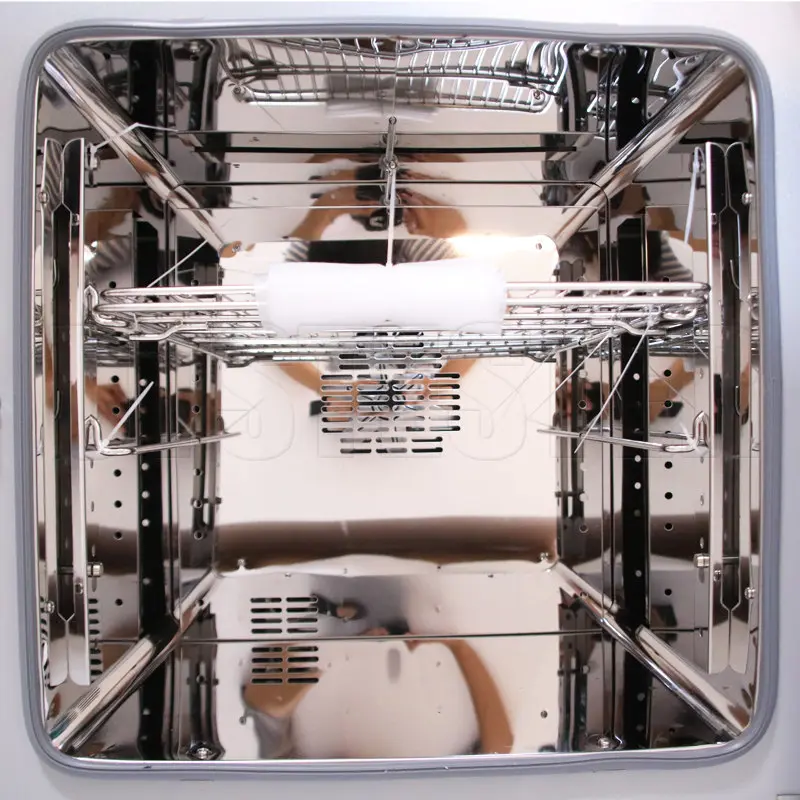

| Shelf | 2 pcs | 3pcs | 4pcs | ||||

| Power supply |

AC 220V 50HZ |

| Temp. |

RT+10~300℃ |

| Temperature Fluctuation |

±1.0℃ |

| Temperature resolution |

0.1℃ |

| Temperature uniformity |

±3% (Test point is 100℃) |

| Working temp. |

+5~40℃ |

| Heating rate |

2-3 °C per minutes |

| Cooling rate |

Natural cooling |

| Working |

Forced air convection |

| Circular Fan |

Available |

Product Details

Production Processes

Scenarios of Use

Operation

Turn on the air door adjusting knob

Turn the damper adjustment knob to the open position,Turn on the power.

Setting parameters

The power indicator light lights up and figures appear on the temperature control instrument. Select the required set temperature.

Instrument heating up

Instrument heating up,Under usual conditions, after heating for 90 minutes, the temperature control will be the constant temperature state.

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home