- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Fabric Testing Machine Moisture Tester for Raw Cotton (Three Layers) F012B

Overview

This instrument is used to measure the moisture regain rate of raw cotton in cotton purchasing and processing departments, cotton textile factories and textile fiber inspection units.

Application

Standards

Standards

Key Parameters

|

Model |

F012B |

|

|

Moisture regain measurement range |

Upper |

7% to 12% |

|

Middle layer |

4%~7% |

|

|

The lower |

9% ~ 15% |

|

|

Using the environment |

temperature 15 ℃ ~ 41 ℃, accuracy ±1 ℃, and the lower can be used in normal when the relative humidity is not more than 85%, middle can be used normally when humidity is not more than 65% |

|

|

Pressure measurement range |

735N±49N |

|

|

Power supply |

dc voltage is 9V (6 batteries, no. 1 dry), the maximum working current is less than 50mA, discontinuously connected |

|

|

Dimensions |

380×280 ×185mm |

|

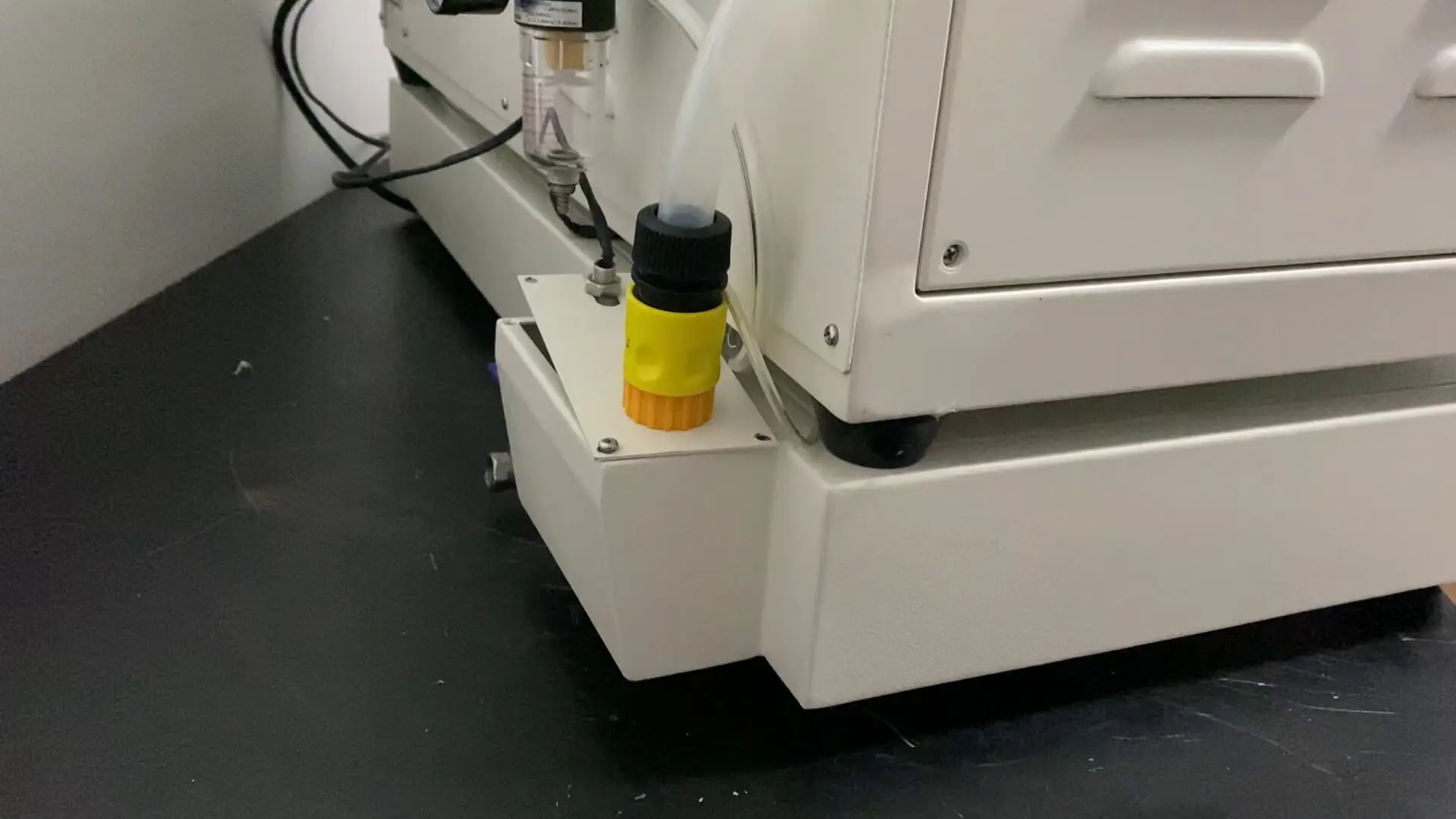

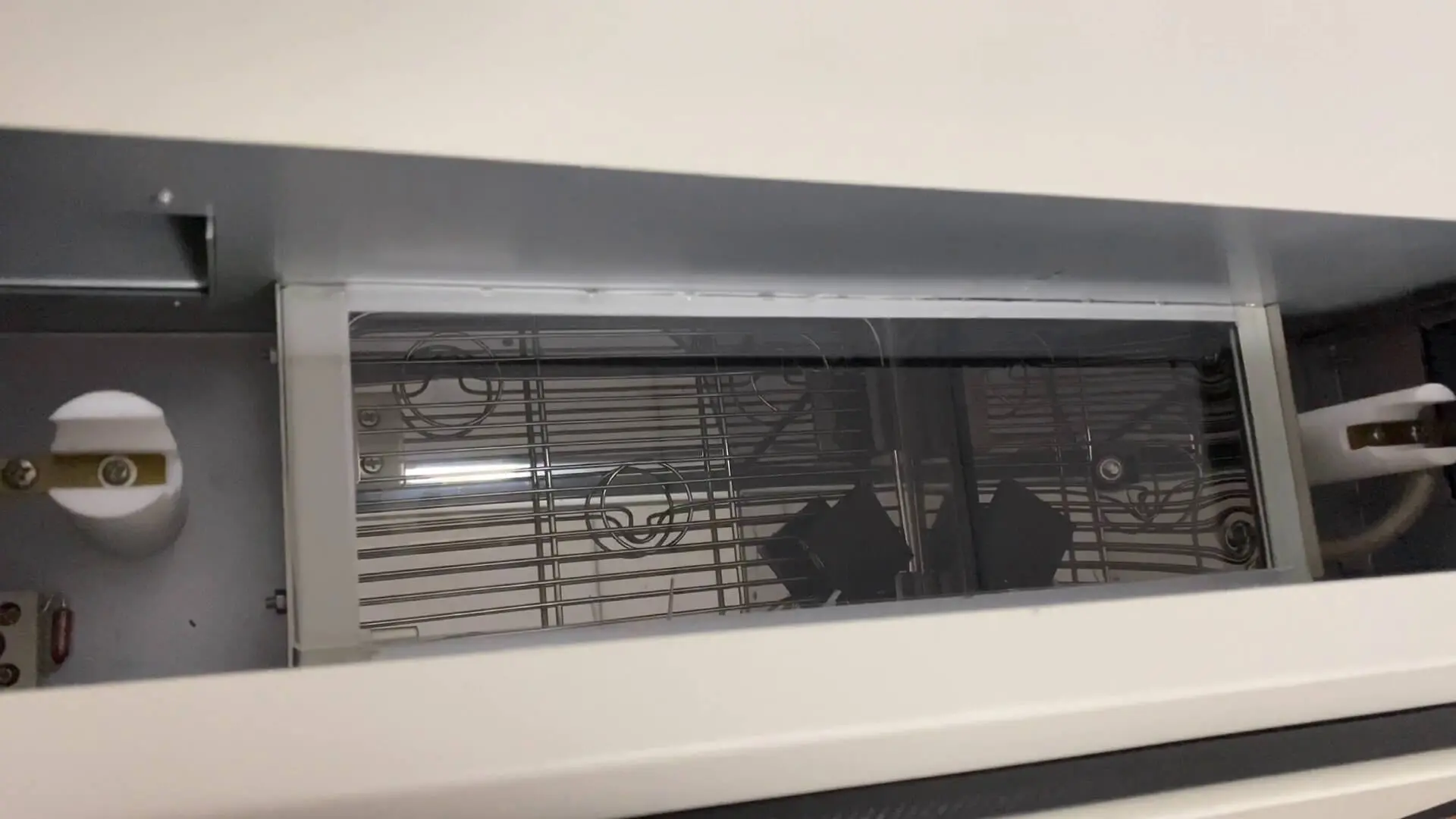

Product Details

Production Processes

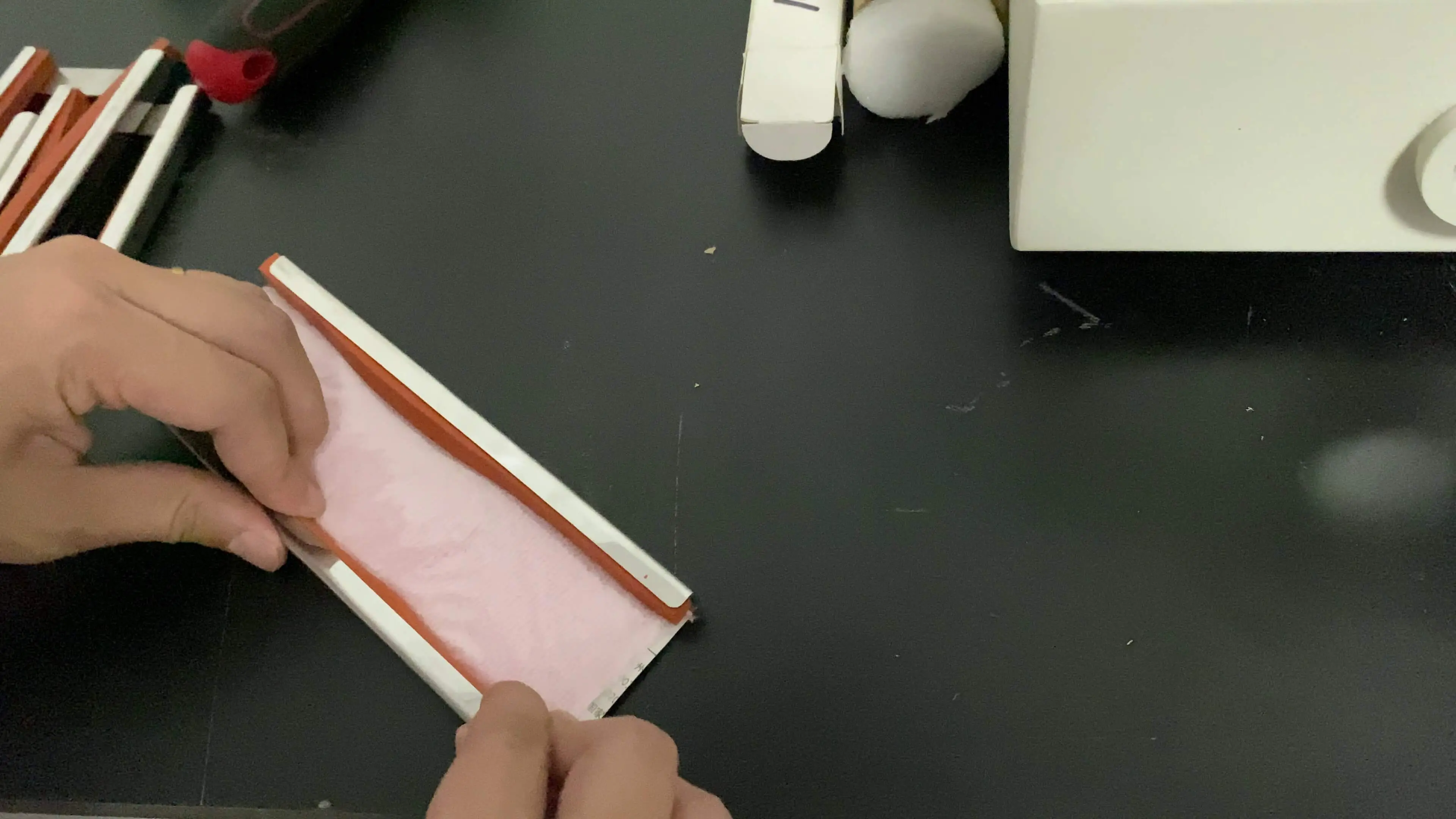

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home