- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

Fire Testing Equipment Insulation Clothing Convection Heat Resistance Tester M050N

Overview

Application

Standards

Key Parameters

|

Model |

M050N |

|

99% pure copper calorimeter |

18g calorimeter piece (Φ40mm, 1.6mm), surface chemical black paint treatment, heat absorption coefficient>0.9, equipped with con copper thermocouple;. |

|

Calorimeter mounting module (Φ89mm, 13mm) |

Made of Monolux500 insulation board with density (750±50)kg/m3 and thermal conductivity 0.18W/(m.K)±10% |

|

Aluminum mass calorimeter positioning plate |

149×149mm, 264g |

|

Copper specimen support frame size |

150×150mm |

|

Propane Meker burner |

Regulate the flow rate to obtain 80kW/m2 heat flux |

|

Pneumatic baffle |

system automatic control, movement time 2s |

|

High-precision data recording system |

time 0.1s |

|

Computer software |

l Test parameters can be set. l Software built-in calibration system, optimize the test process; l Real-time display of the test temperature curve, the software automatically calculates and outputs the material heat transfer index. |

|

Power supply |

AC220V, 50Hz, 500W |

|

External dimension |

500 × 500 × 500mm |

|

Total weight |

50kg |

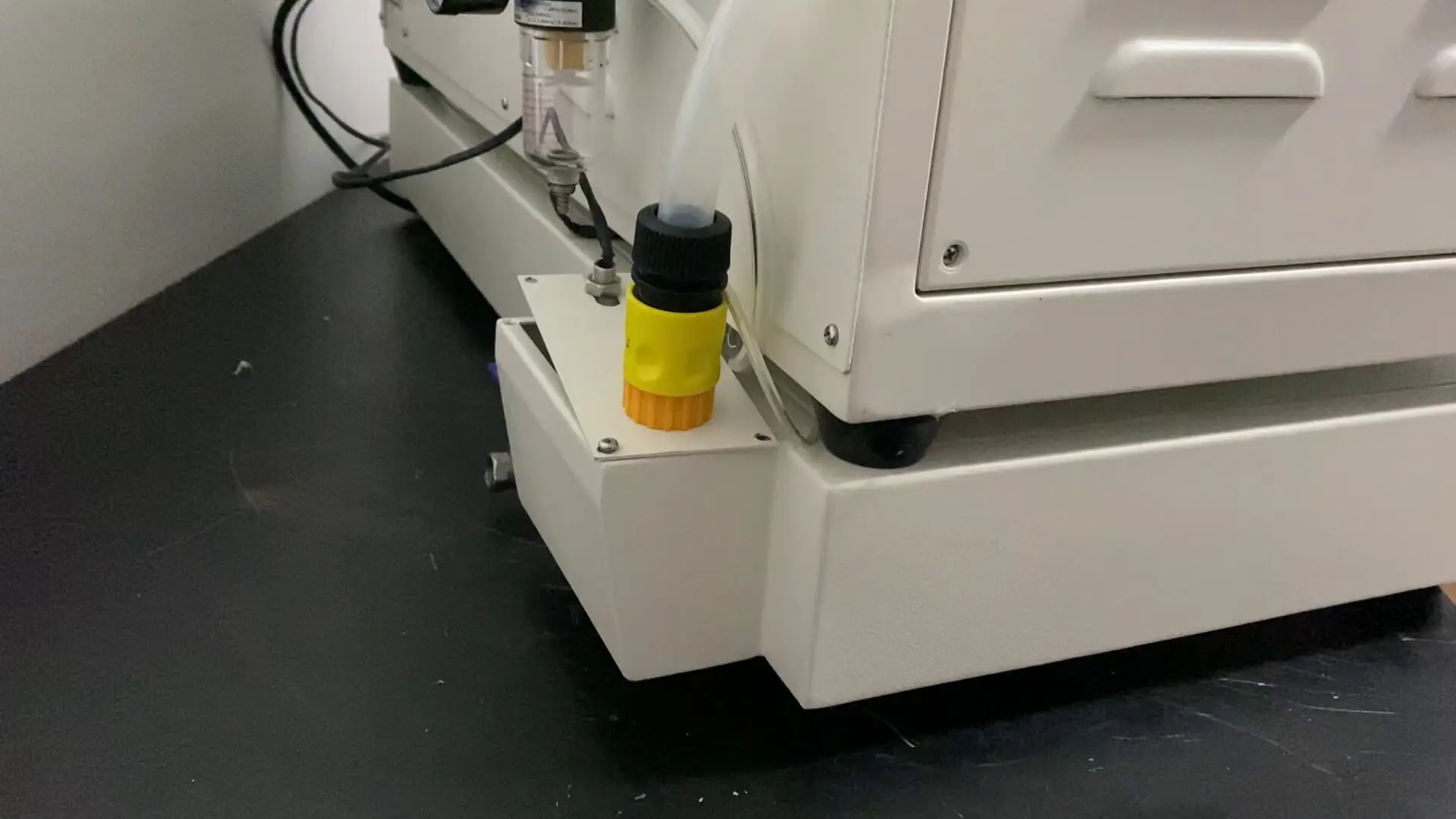

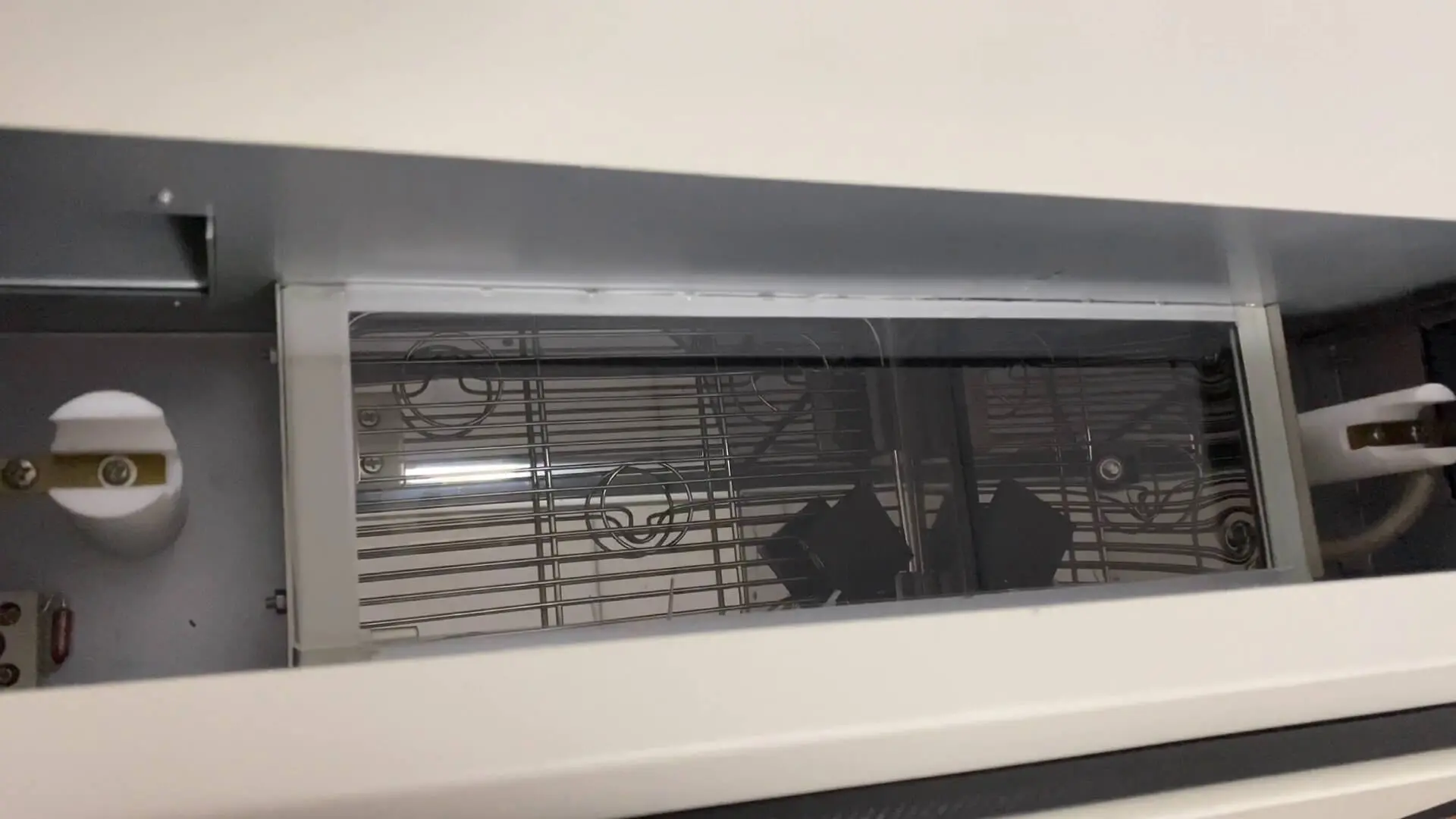

Product Details

Production Processes

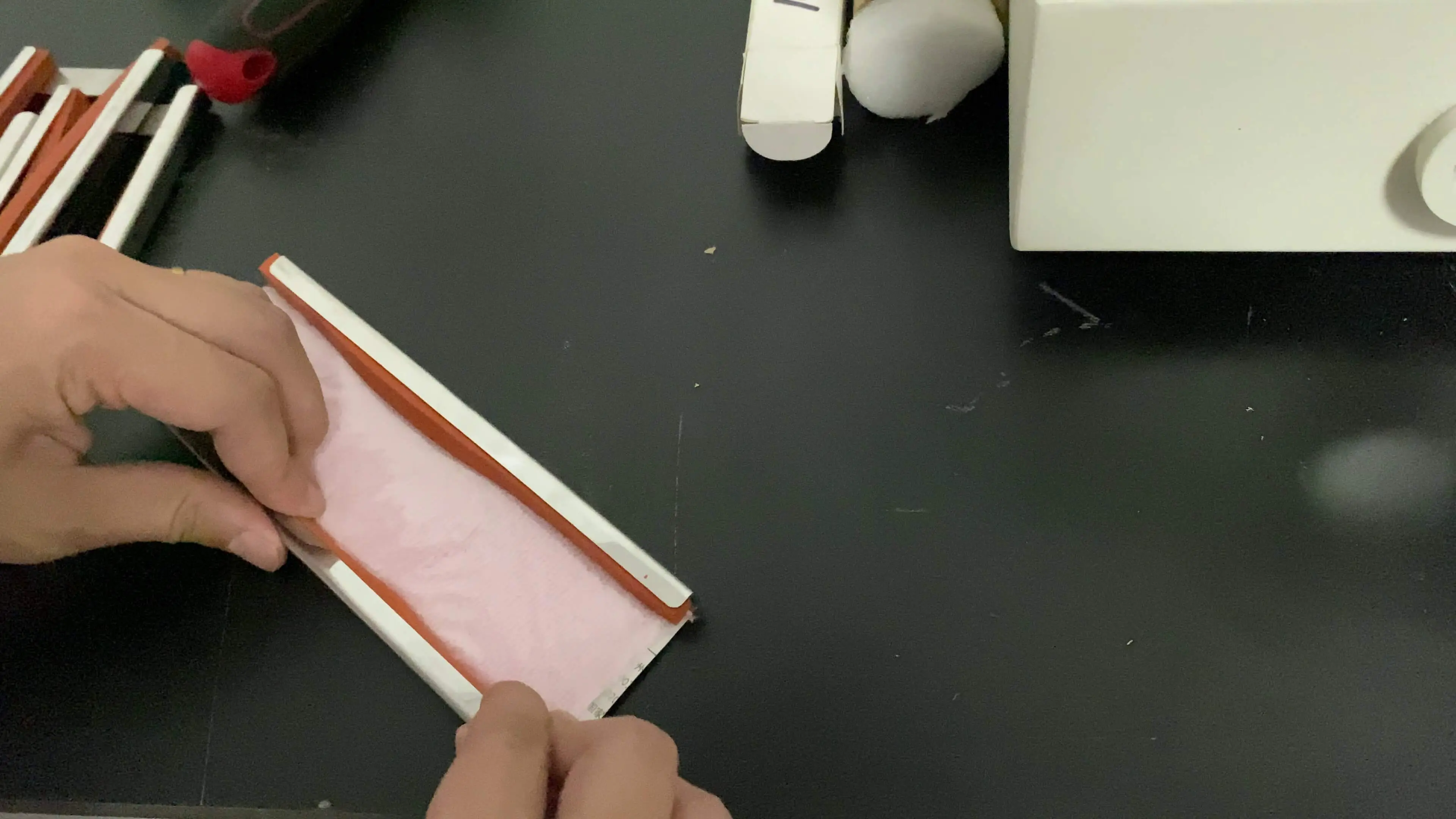

Scenarios of Use

Operation

Transportation

Home

Home