- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Fully Automatic Enclosed Dry Cleaning Machine D031

Overview

This instrument is suitable for dry cleaning test of woolen, fur, cotton, linen, wool, chemical fiber and other fabrics

Application

Standards

GB11401.1-89 "Appearance and dimensions of hot melt adhesive interlining after dry cleaning-determination of change"

FZ/T01013-91 "Determination of Dimensional Change of Textile Perchloroethylene Dry Cleaning-Mechanical Method"

FZ80007.3-99 "Test Method for Dry Cleaning Resistance of Clothing Using Fusible Interlining"

ISO3175.1-1: 1998 "Textiles-Dry Cleaning and Finishing-Part 1: Methods for Evaluating the Detergency of Textiles and Clothing"

ISO3175.1-2: 1998 "Textiles-Dry Cleaning and Finishing-Part 2: Procedures for Perchloroethylene"

Key Parameters

|

Model |

D031 |

|

Rated capacity |

≤6kg/time (φ650×320mm) |

|

Liquid tank capacity |

100L (2×50L; 3 boxes for spare) |

|

Distillation box capacity |

50L |

|

Washing agent |

C2Cl4 |

|

Washing speed |

45r/min |

|

Dehydration speed |

450r/min |

|

Drying time |

4~60min |

|

Drying temperature |

adjustable to 80℃ |

|

Noise |

≤75dB(A) |

|

Installed power |

22kW |

|

Use power |

10.5kW |

|

Air pump |

Model number: Z~0.12/T pressure: 6.3Kg/cm2 |

|

Voltage |

Three-phase four-wire system AC 380V 50Hz |

|

Dimensions |

1560×1100×2080mm |

|

Weight |

850kg |

Product Details

Production Processes

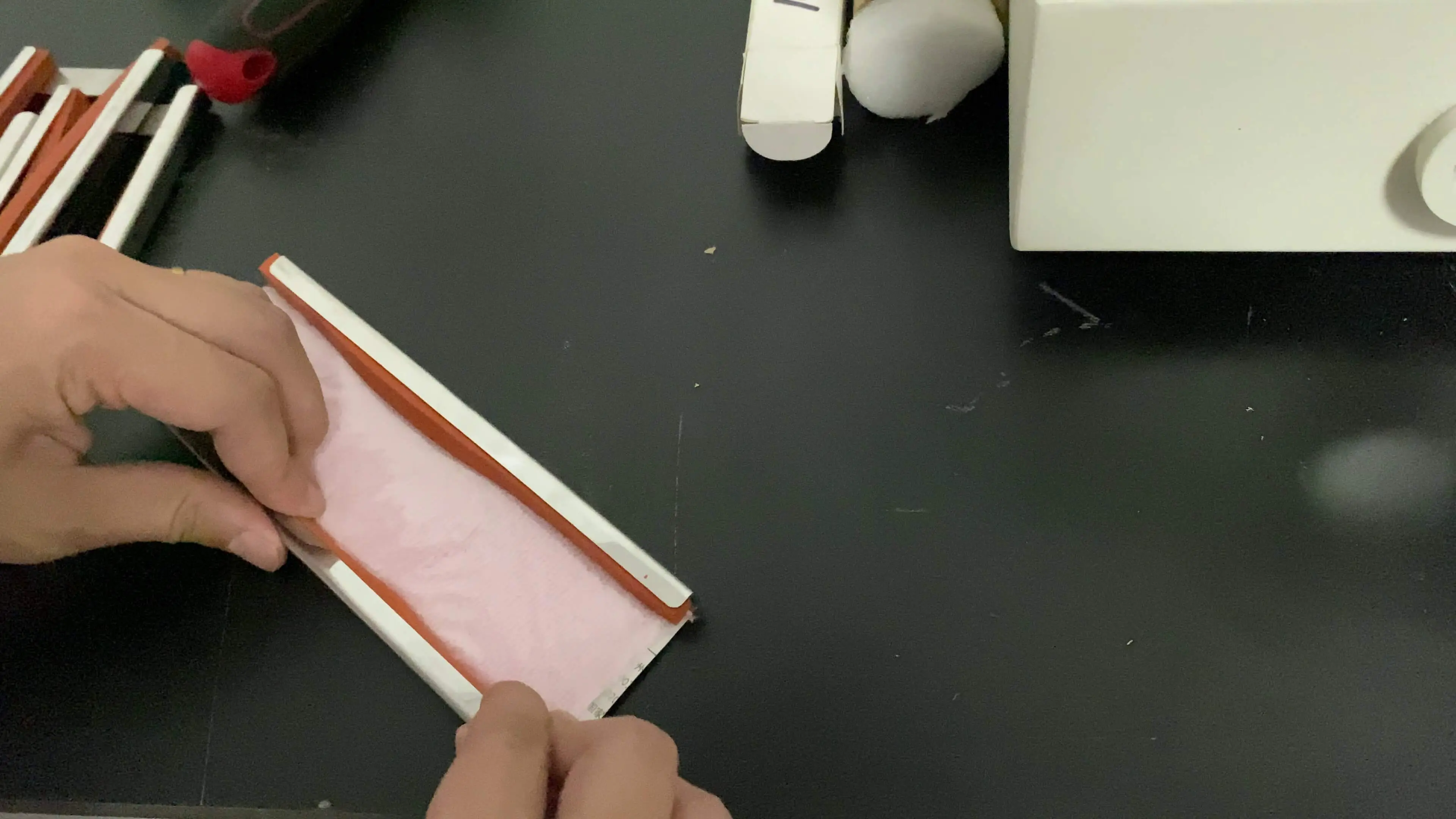

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home