- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

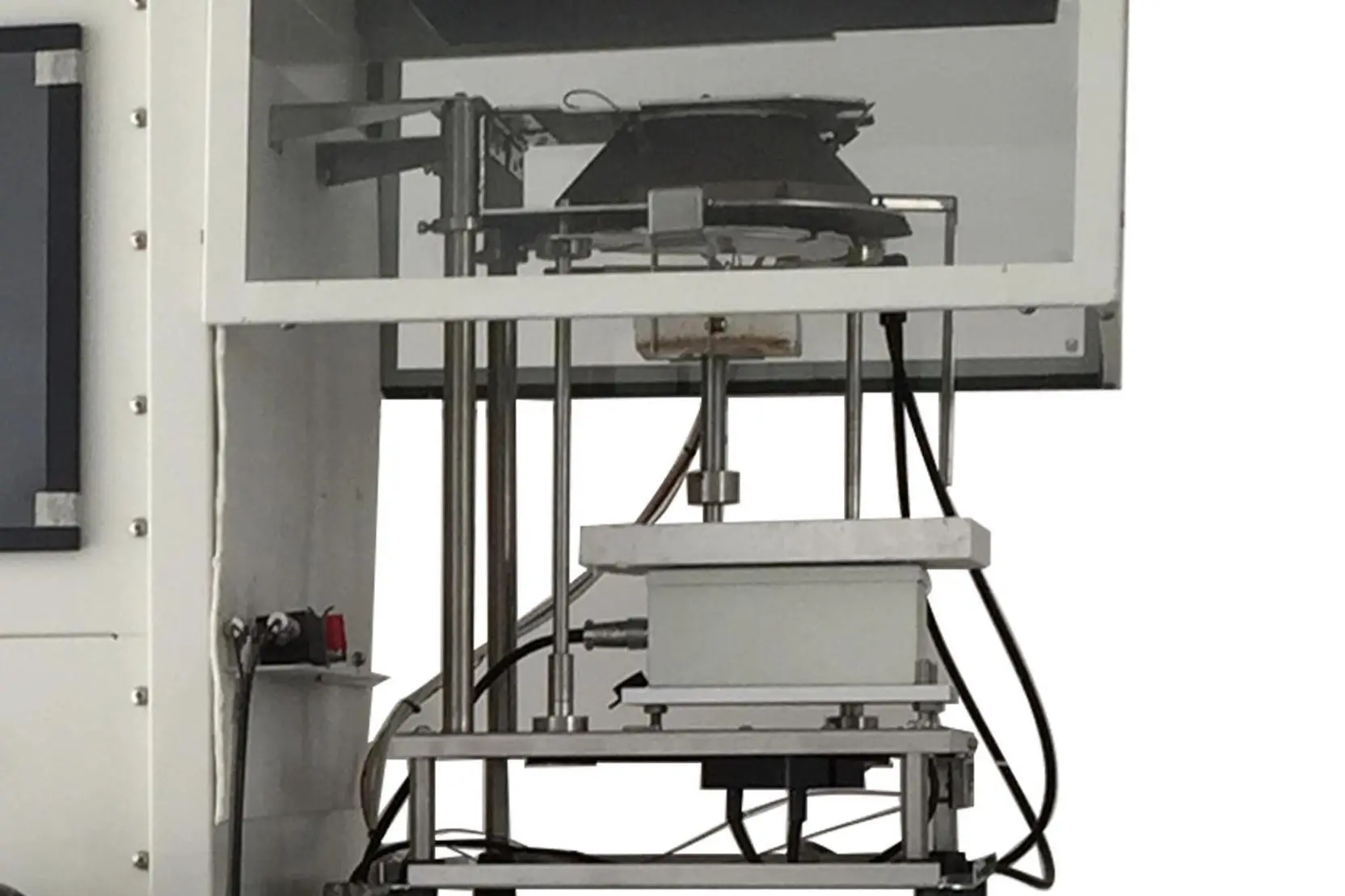

ISO 5660 Cone Calorimeter of Building Materials Heat Release Rate Flammability Tester M103

Overview

Application

Standards

FAR 25.853, ISO 5660-1&2, ASTM E1354, ASTM E1474, ASTME1740, ASTM F1550, ASTM D5485, ASTM D6113, CAN ULC 135, BS 476 Part 15

Key Parameters

|

Burning chamber |

It is composed of cone heater, 10KV igniter, weigher, windshield and so on |

||

|

Cone heater Homemade, high temperature resistant alloy

|

Power |

5KW |

|

|

The radiation intensity of illumination |

0-100KW/M2 |

||

|

Central radiation bias |

±2% |

||

|

Thermocouple temperature deviation |

±5℃(data measurement in 30 minutes) |

||

|

Control thermocouple |

1.5mm Armor type K, 3 units(imported OMEGA) |

||

|

10KVigniter |

High pressure impulse igniter, automatic ignition in place (inlet) |

||

|

Radiation shield |

Insulation |

High temperature heat pad |

|

|

thickness |

3mm |

||

|

material |

304 stainless steel |

||

|

Weighing system |

Capacity |

3000g(Imported Germany HBM weighing sensor) |

|

|

Accuracy |

±0.05 |

||

|

resolution |

0.1g |

||

|

In 30 Minute drift |

Less than 0.05g |

||

|

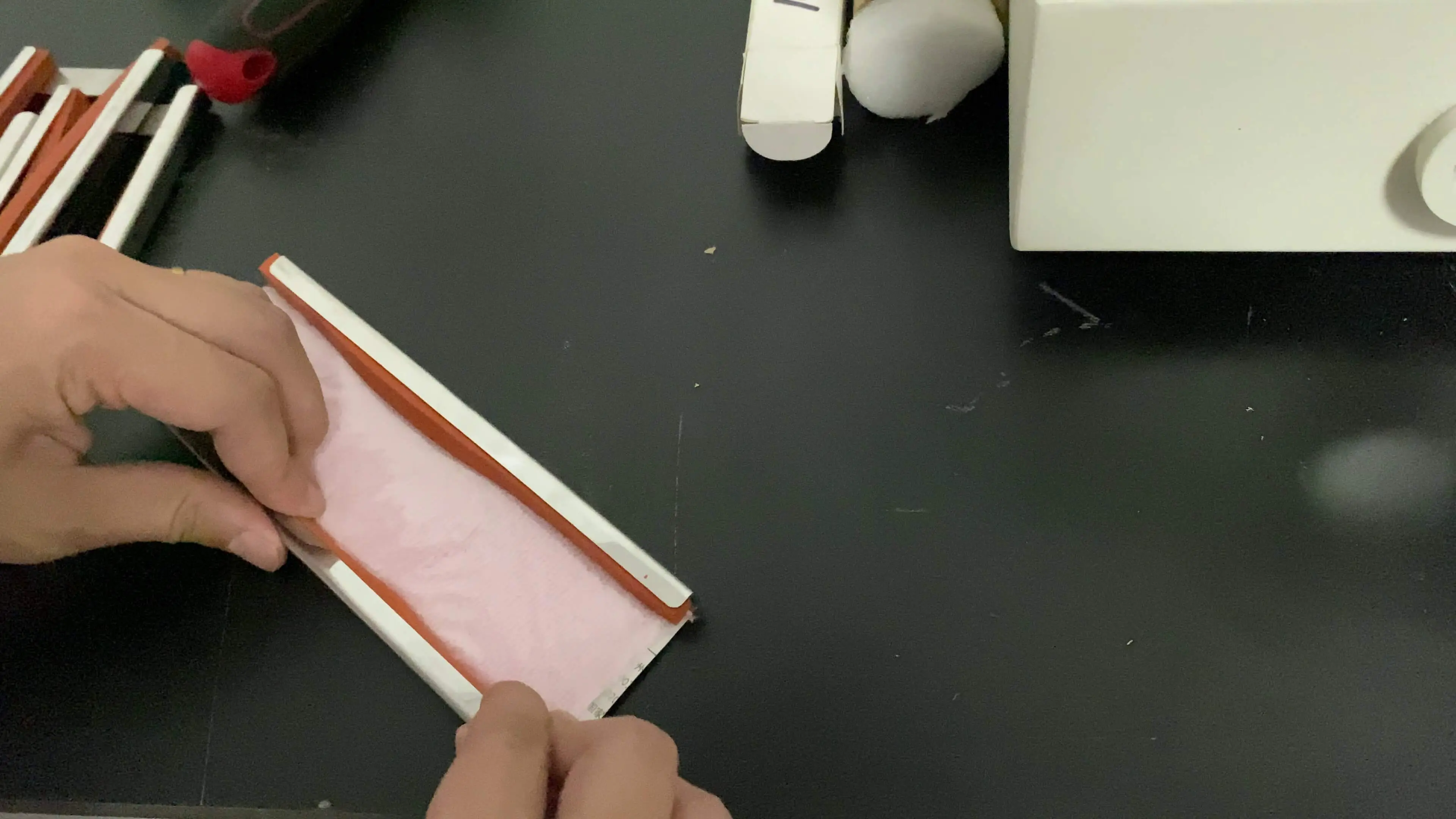

Sample mounting bracket |

Top opening 106*106mm depth 25mm |

||

|

Thickness |

2.4mm |

||

|

Positioning frame

|

Thickness |

1.9mm |

|

|

Inside edge size |

111*111 |

||

|

Sample opening |

94*94 |

||

|

Protective cover |

Semi-closed toughened glass cover, open up by turning over |

||

|

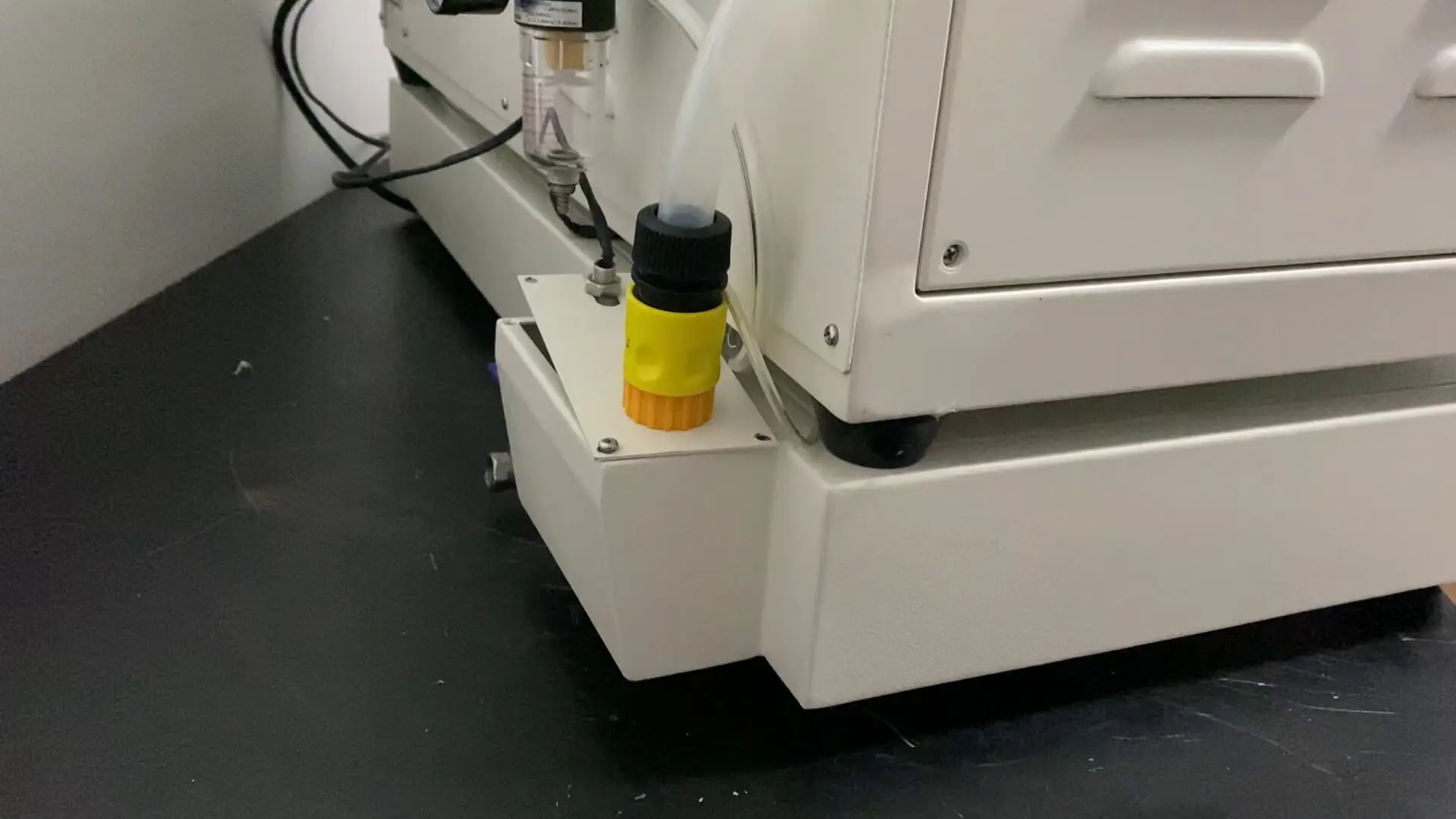

Gas system |

The system consists of exhaust system, sampling system, smoke density measurement system and data collection system |

||

|

Sampling device |

Include import sampling pump, dust edge filter, dehumidifying cold well, emptying bypass system, water filter, carbon dioxide filter |

||

|

Gas acquisition system 4100 special type analyzer |

Paramagnetic oxygen analyzer |

Servomex, capacity: 0-25% |

|

|

CO analyzer |

Servomex, capacity: 0-1% |

||

|

CO2 analyzer |

Servomex, capacity: 0-10% |

||

|

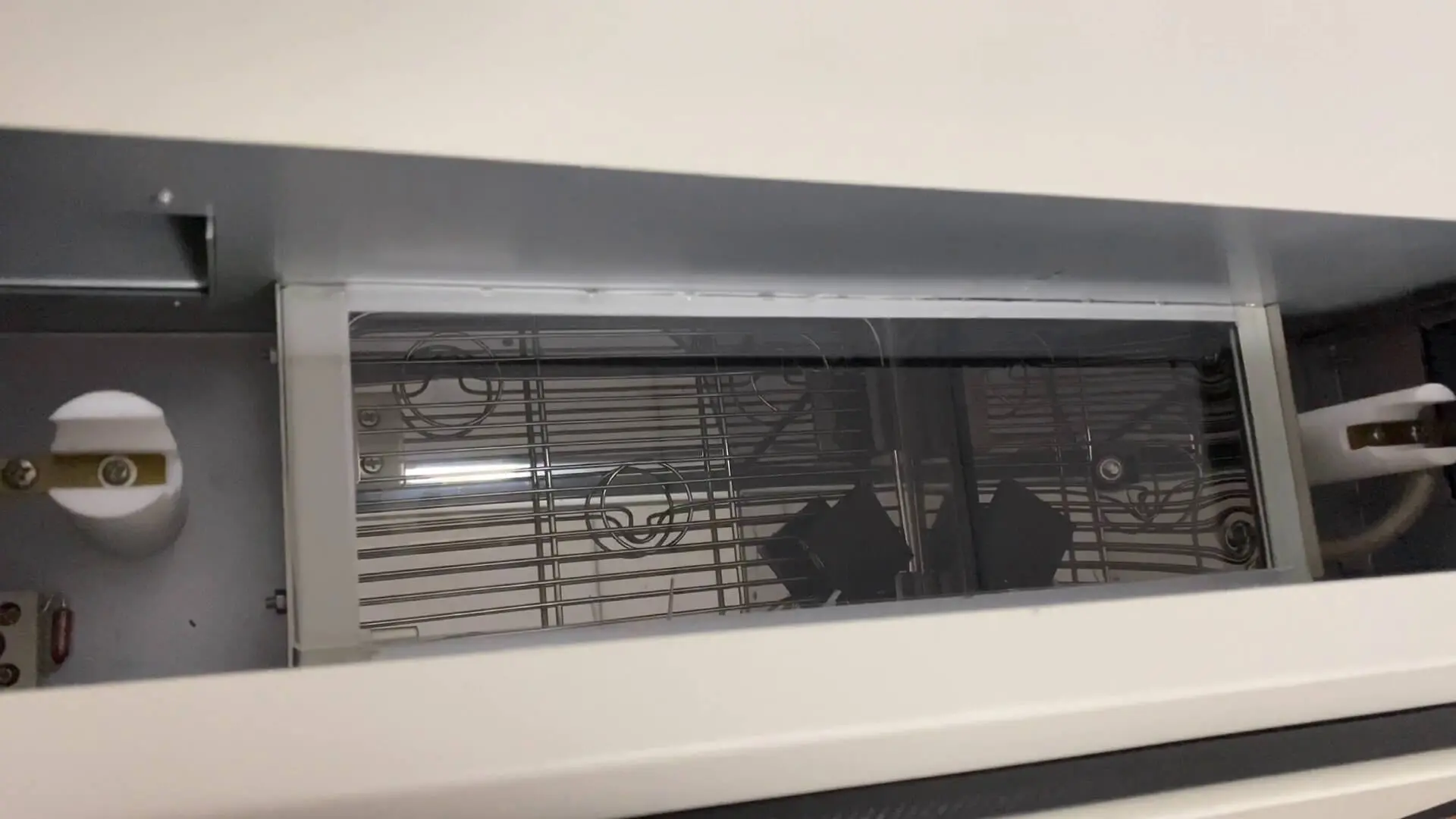

Smoke density measurement |

Helium-neon laser Laser transmitters and receivers (The U.S.A import) |

||

|

Gas sampling system |

Inlet diaphragm sampling pump, convenient to adjust to standard flow rate: 0.024 m3 / s + 0.02 flow rate 33L/ min |

||

|

Imported micro pressure differential sensor |

Setra (The U.S.A import) |

||

|

Mass flow controller |

Japan KOFLOC |

||

|

The compressor |

The French taikang |

||

|

Cold trap |

Homemade patented product |

||

|

Analytic system |

It is composed of standard instrument rack, test software, touch industrial control computer and imported sensor |

||

|

Instrument stand |

19 inch standard instrument rack, 9002 standard color coating, 1.5mm thick |

||

|

Control computer |

Taiwan research - China special industrial control mainframe, 17 inch color display |

||

|

The test software |

Calibration of each sensor mode, including single point or double point calibration of oxygen analyzer, carbon dioxide analyzer, carbon monoxide analyzer, micro pressure difference sensor, smoke density measurement system, weighing device, mass flow control, for optimal linearity |

||

|

C- coefficient calibration. The software can automatically set the gas flow at the measurement of C coefficient, such as 1KW, 3KW or 5KW |

|||

|

The software can automatically generate c-coefficient log, so that users can check the historical state of the cone calorimeter by themselves, and distinguish the accuracy and stability of their own system |

|||

|

The system can calculate the delay time of oxygen analyzer, carbon dioxide analyzer and carbon monoxide analyzer by itself, which is convenient for synchronous calculation and use |

|||

|

The report template is in excel format to display graphics and numerical patterns |

|||

|

The test results include: heat release rate, flue gas flow rate, C coefficient, sample ignition and quenching time, total oxygen consumption, specific extinction area, total smoke generation, mass loss rate, total heat release, effective combustion heat, carbon dioxide production and carbon monoxide production, etc |

|||

|

Software by NI LABVIEW platform, standardized test interface |

|||

|

The sensor |

Heat flow meter: MEDTHERM(standard specified brand) |

||

|

Pressure sensors: U.S.A SETRA |

|||

|

Temperature sensor: U.S.A omega |

|||

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Home

Home