- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

Lab Vat Thermosol Range Steam Continuous Vat Dyeing Machine D024

Overview

Application

Standards

Standards

Key Parameters

|

Model |

D024 |

|

Internal chamber capacity |

6M |

|

Roller diameter |

126mm |

|

Roller hardness |

Shore 70 degree |

|

Roller pressure |

0.03 - 0.6Mpa |

|

Power consumption |

400W |

|

Machine Material |

High quality SUS 304 stainless steel |

|

Consist |

Pneumatic electric small padder and a saturated steam box unit. |

|

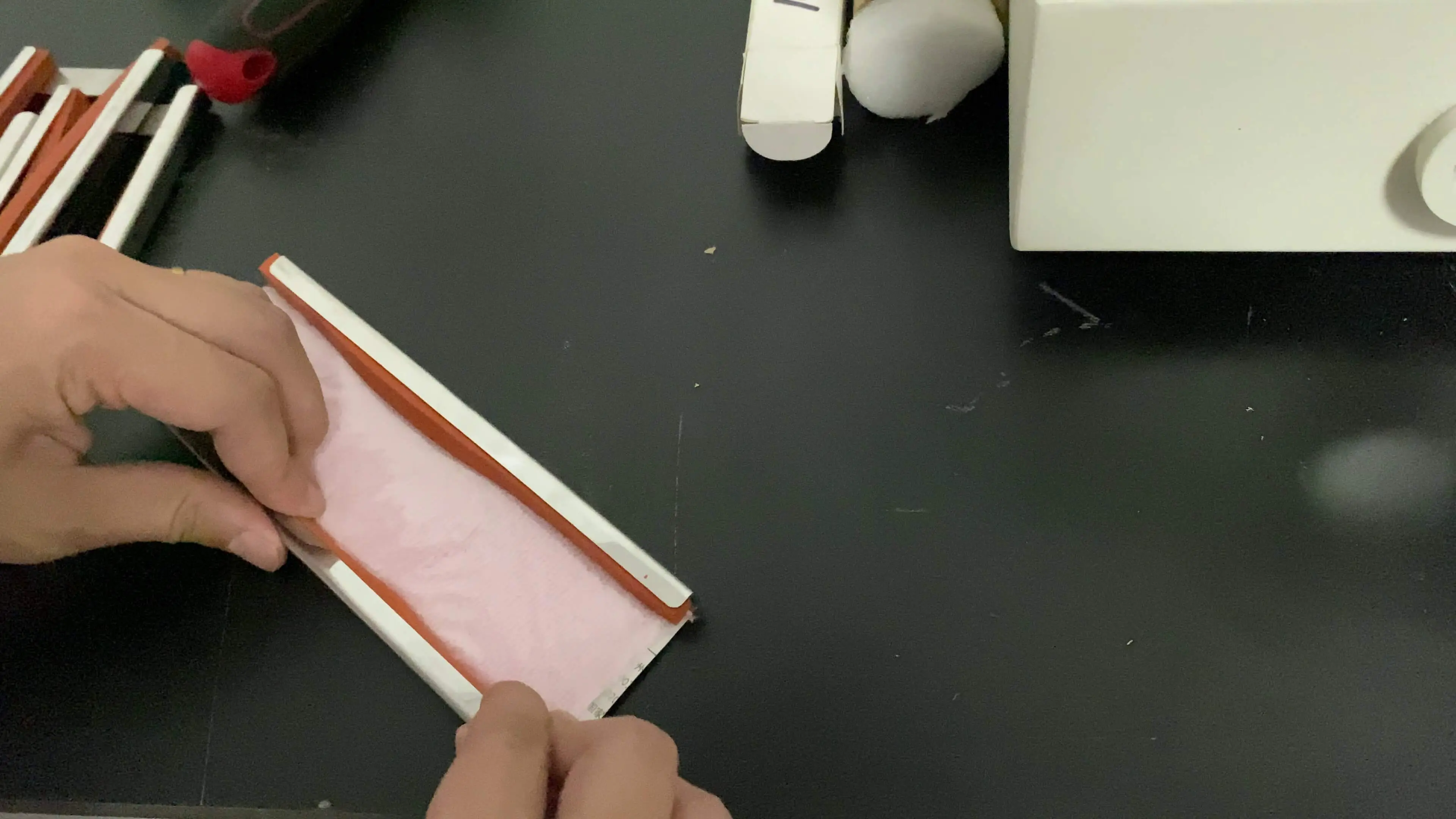

Roller |

Horizontal, butadiene rubber roller, good elasticity, long service life. Compressed air to push the film, roll pressure uniform, no left or right deviation, strong stability |

|

Roller length |

300mm ( Can be customized for 350-600mm) |

|

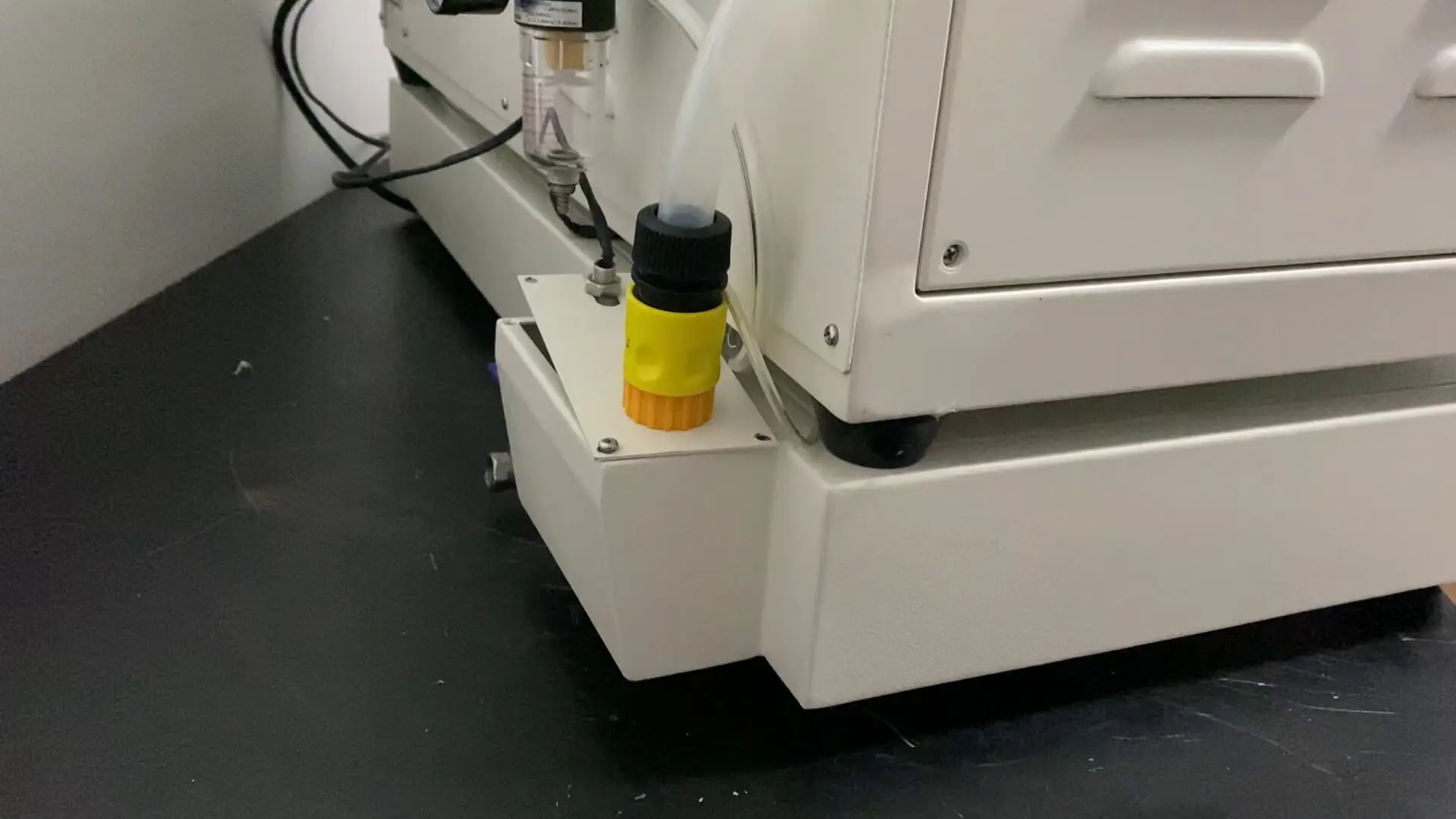

Safety device |

Emergency stop button and foot switch. |

|

Frequency control |

Auto set time of sample cloth passing through steam tank. |

|

Liquid tank |

The tank capacity is 500CC, which can be automatically cleaned by water spraying. |

|

Cloth guiding roller |

Using high quality stainless steel, teflon processing, cleaning convenient and fast |

|

Cylinder |

arge section thin film cylinder, strong resistance to guide friction, power automatic reset, easy to adjust. |

|

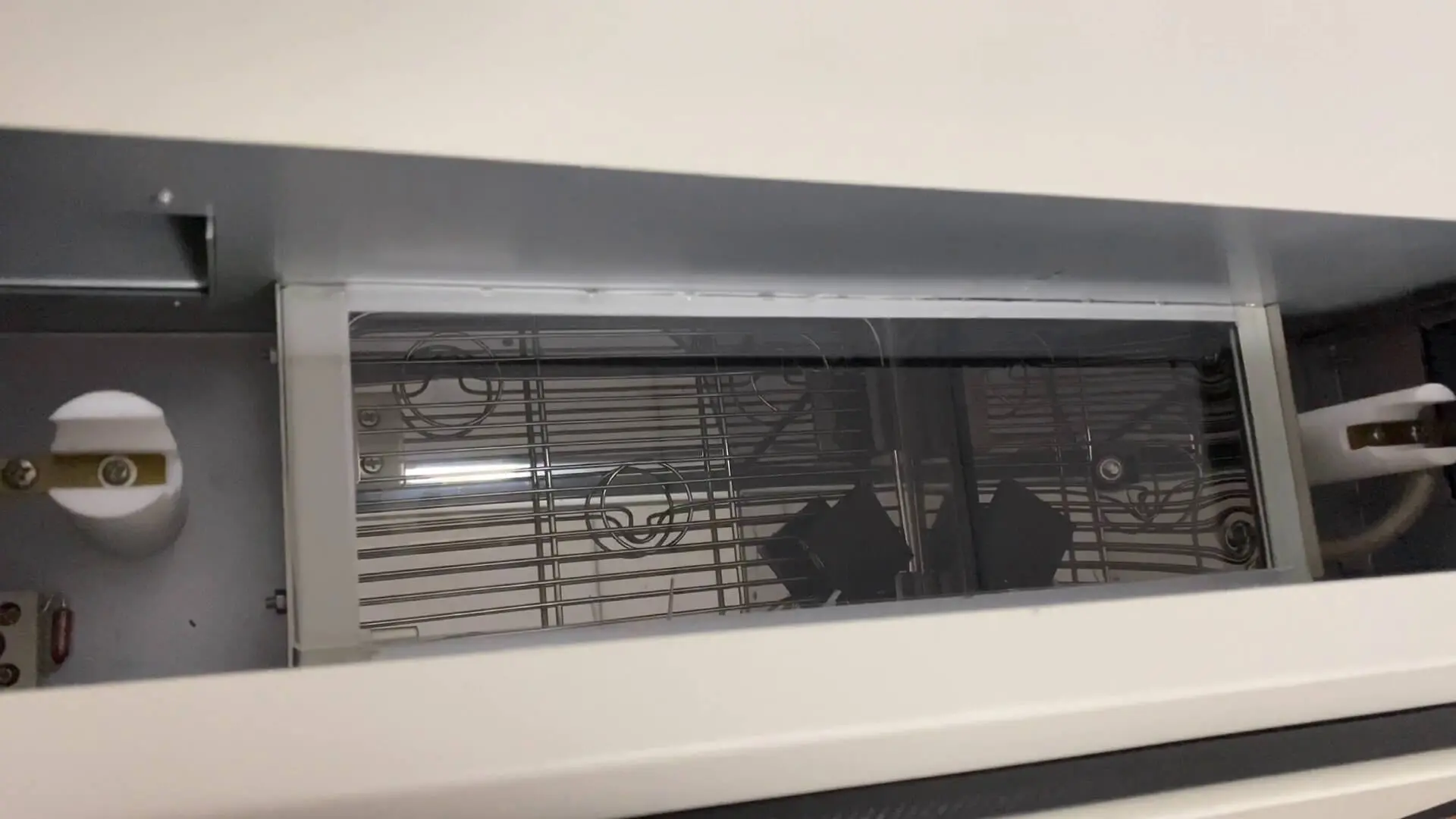

Steaming chamber Part |

The inlet is sealed with steam seal; The outlet of the steam box is sealed with water seal groove. Automatic control of outlet temperature control, with water temperature regulation, automatic water replenishment function. |

|

Steaming chamber |

Steaming ensure 4-5kg/c,m2, Hot air circulation, uniform distribution, stable |

|

Power supply |

220V, 50HZ, 1PHASE, AC |

|

Dimension |

840 x 1400 x 1800 mm (L x W x H) |

|

Weight |

250kg |

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Home

Home