- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

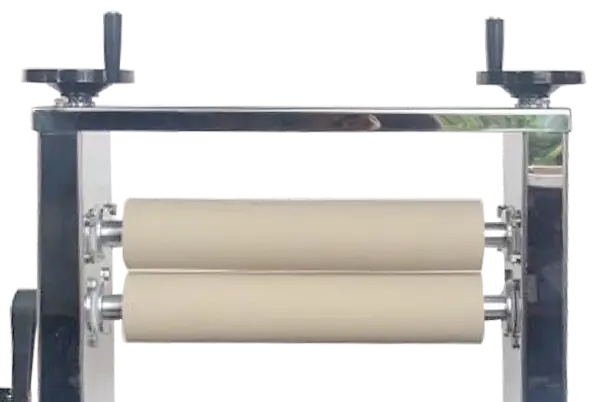

Manual Padder Mangle Hand-Cranked Small Roller Mill Electric Roller D022M

Overview

Laboratory Padder /Mangle is designed to test the effect of the small batch various types of dyeing fabrics, and assess the pressure absorption rate of fabrics, or dyeing fabrics and post-treatment effect and quality testing.

It is on the basis of absorbing foreign small same type rolling cars combine the domestic current situation of the pad dyeing post-processing technology digestion renovation and become one of the most advanced pad dyeing small prototype.

Application

Key Parameters

|

Model |

D022M |

|

Material |

SUS 304 stainless steel with high quality mirror |

|

Roller |

Material: NBR Hardness: Shore 70° Diameter: 80 mm Length: 400 mm |

|

Operation |

pressure mode and rotation mode are manual. Rotation way: Right hand. |

Product Details

Production Processes

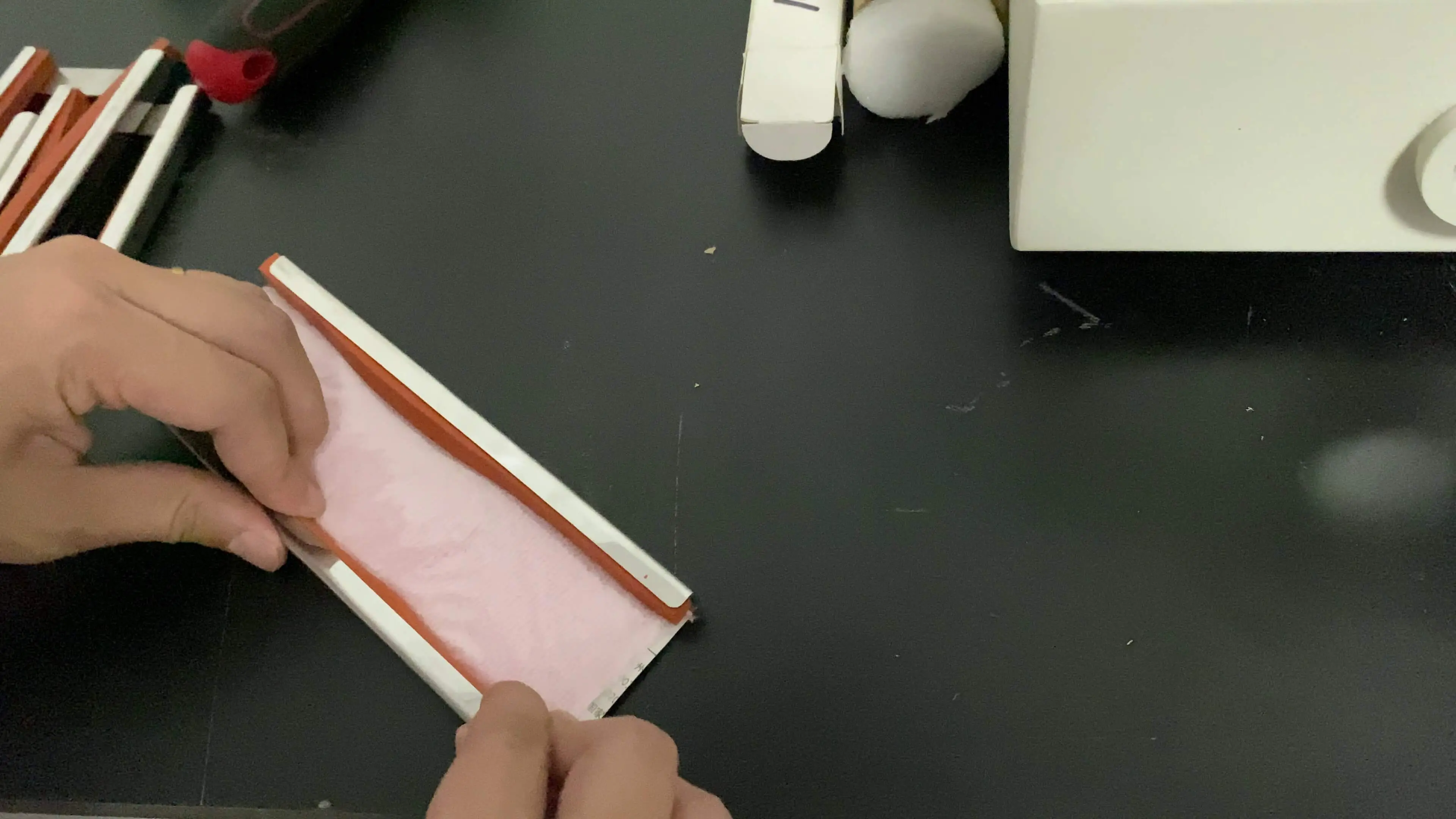

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home