- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

010203

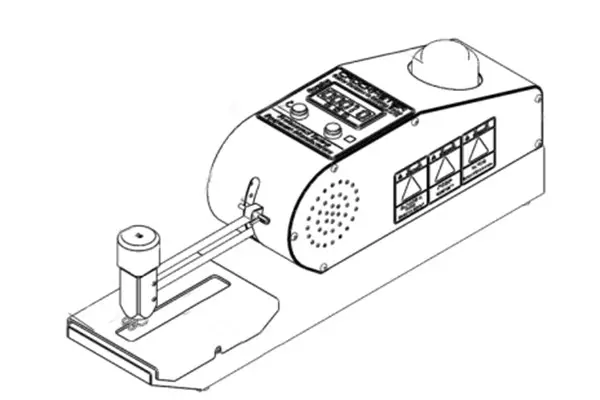

Martindale Abrasion Tester Martindale Wear and Abrasion Tester

Overview

Martindale wear and abrasion tester, available with up to 9 stations and adaptable to test a wide range of applications - socks, textiles, leather, carpets, coated upholstery, and shirt collars.

This machine is ideal for wear-resistant testing of various types of fabrics and leather footwear, upholstery, garments, gloves and other such products. Martindale is internationally recognized as a abrasion resistant test standard for fabrics and can also be used to test the pilling performance of fabrics.

H056 Martindale tester can also be used for abrasion resistance and durability of rubber gloves, plastic and rubber coatings, plastic and rubber coated fabrics, using a piece of granulated sandpaper instead of a standard abrasives.

The machine can be used to test the dirty condition of light-colored materials. In such tests, a special ink-printed fabric is used instead of a standard friction agent.

A small amount of standard abrasive cloth is supplied with the machine.

Application

Standards

ASTM D4966, BS-3424, DIN-53863, GB/T 20991,

SATRA TM31, ISO 5470-2, GB/T 19089, GB/T 3903.16 ,

EN ISO 12947, EN ISO 20344:6.12, BS EN 388:2003

Key Parameters

|

Model |

H056A |

|

Working positions |

4 |

|

Load |

595 g , 795 g |

|

Control mode |

LCD 0~99,999,999 |

|

Pressure plate |

SUS 304 stainless steel |

|

Lissajous figure |

60±1 mm x 60±1 mm |

|

Power supply |

1∮, AC 220V,3A |

|

Dimensions |

60x 60 x 35 cm ( L x W x H ) |

|

Weight |

67kg |

Production Processes

Scenarios of Use

Operation

Remove the loading axes

Remove the four weights and the loading axes from the abrasion machine.Place the spanner over the fixed ring, and counterclockwise rotate to remove the abrasive head.

Put in sample

Place successively the specimen in its carrier with the surface to be tested facing outwards, the cellular pad , and then the abrasive head. Lock the fixed ring at last.

Wool felt and abrasive fabric device

Place successively the wool felt onto the holder, the abrasive fabric , and then the platen of 2 ±0.2kpa on the right central part. Lock the fixed ring and remove the platen finally.

Mounting Bracket

Put the carriers having specimens on the corresponding holders with the front face of the specimen contacting with the abrasive fabric.

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home