- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Melting Point Apparatus Melt Index Meter (Mass and Volume Method) HP03-MV

Overview

HP03 Touch screen melt index meter used to measure the MFR value of various plastics and resins passing through a certain temperature and load in a viscous flow state, passing through a standard die melt flow rate every 10 minutes. It is suitable for polycarbonate, polyarylsulfone, fluorine, etc. Plastic, nylon and other engineering plastics, also suitable for polyethylene (PE), polystyrene (PS), polypropylene (PP), ABS resin, polyoxymethylene (POM), polycarbonate (PC) resin, etc., with low melting temperature Plastic testing is widely used in plastic production, plastic products, petrochemical and other industries as well as related universities, scientific research units and commodity inspection departments.

Application

Standards

(1)GB/T3682-2018 "Determination of Melt Flow Rate and Melt Volume Flow Rate of Thermoplastics"

(2)ISO 1133: 1997 "Determination of melt mass flow rate MFR and melt volume flow rate MVR of thermoplastics"

ASTM D1238 "Standard test method for melt flow rate of thermoplastics using an extrusion plastometer"

Key Parameters

|

Model |

HP03-MV |

|

Temperature range |

RT-450℃ |

|

Temperature fluctuation |

±0.2℃ |

|

Temperature uniformity |

±1℃ |

|

Temperature display resolution |

0.1℃ |

|

Time display resolution |

0.1S |

|

Test result range |

0.1-300g/10min |

|

Barrel diameter |

Φ2.095±0.005mm |

|

Outlet length |

8.000±0.025mm |

|

Diameter of charging barrel |

Φ9.550±0.025mm |

|

Weight accuracy |

±0.5% |

|

Output method |

miniature automatic printout |

|

Cutting method |

manual and automatic cutting |

|

Test load |

a full set of eight-level weights |

|

Displacement accuracy |

0.001mm |

|

Volume timing |

0.001S |

|

Mass method test range |

0.1-150g/10min |

|

Volume method test result range |

50-5000cm³/10min |

|

Power supply |

AC220V±10% 50HZ |

|

Packing size |

69×56×76cm |

|

Gross weight |

69kg |

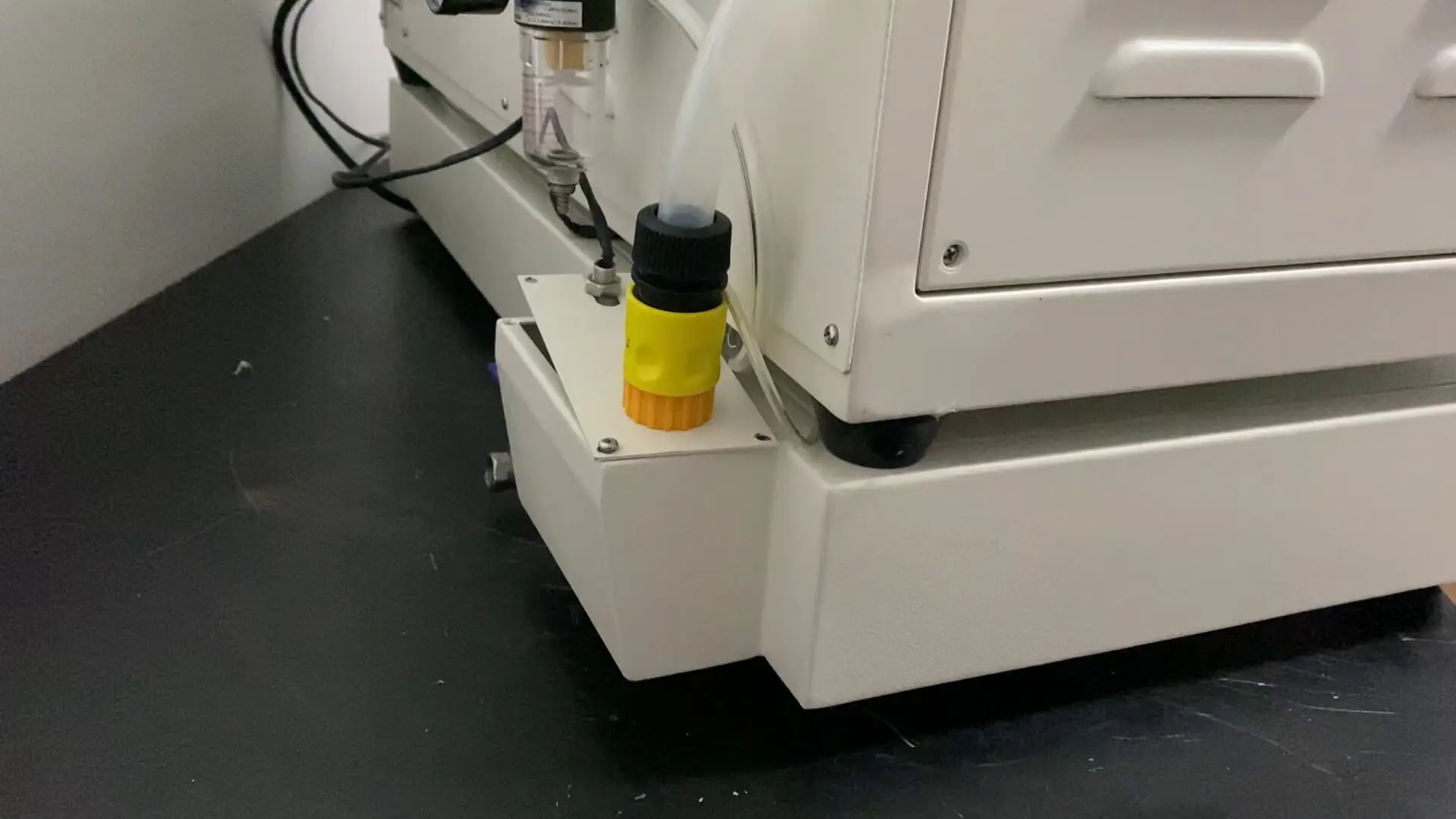

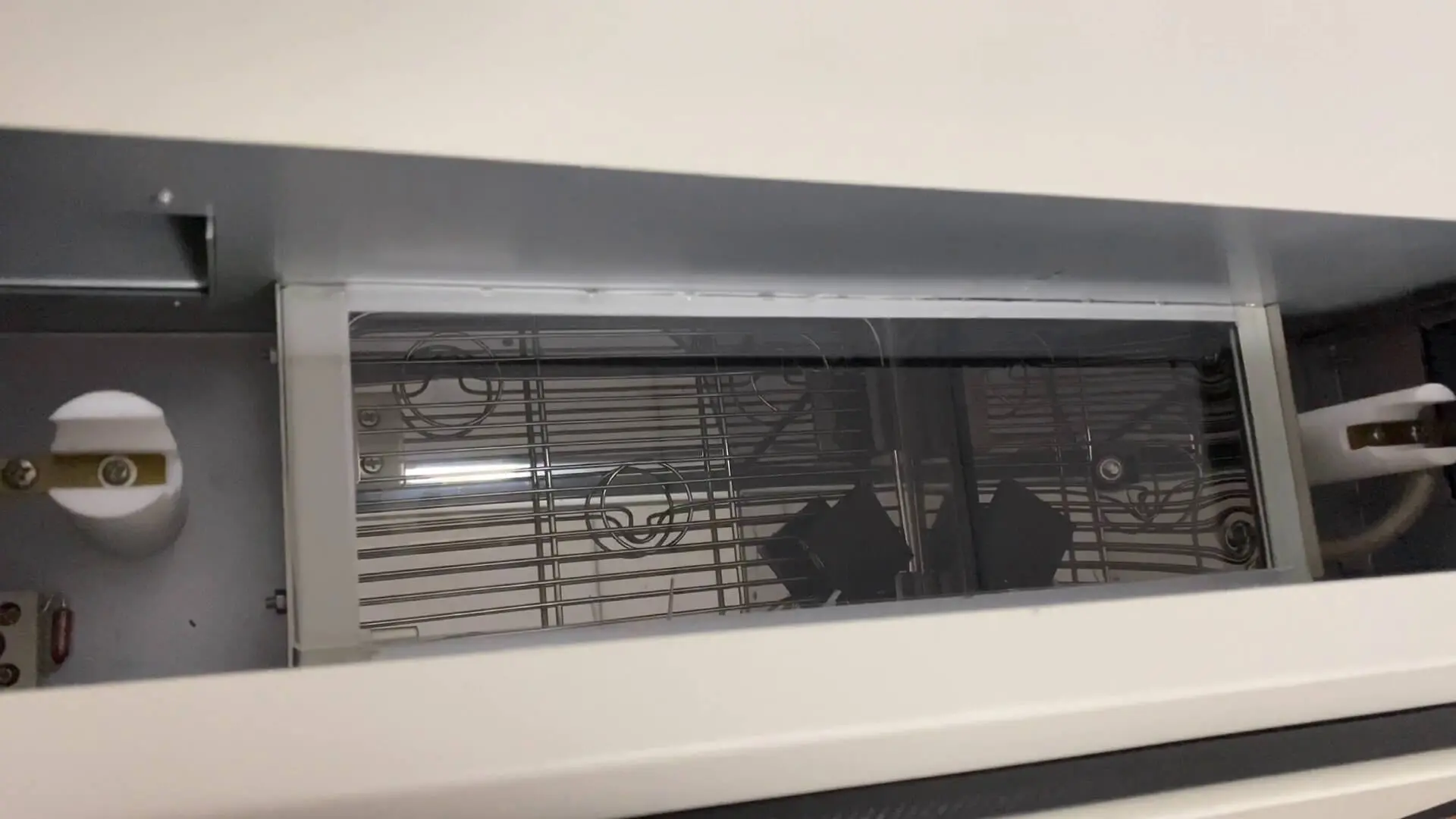

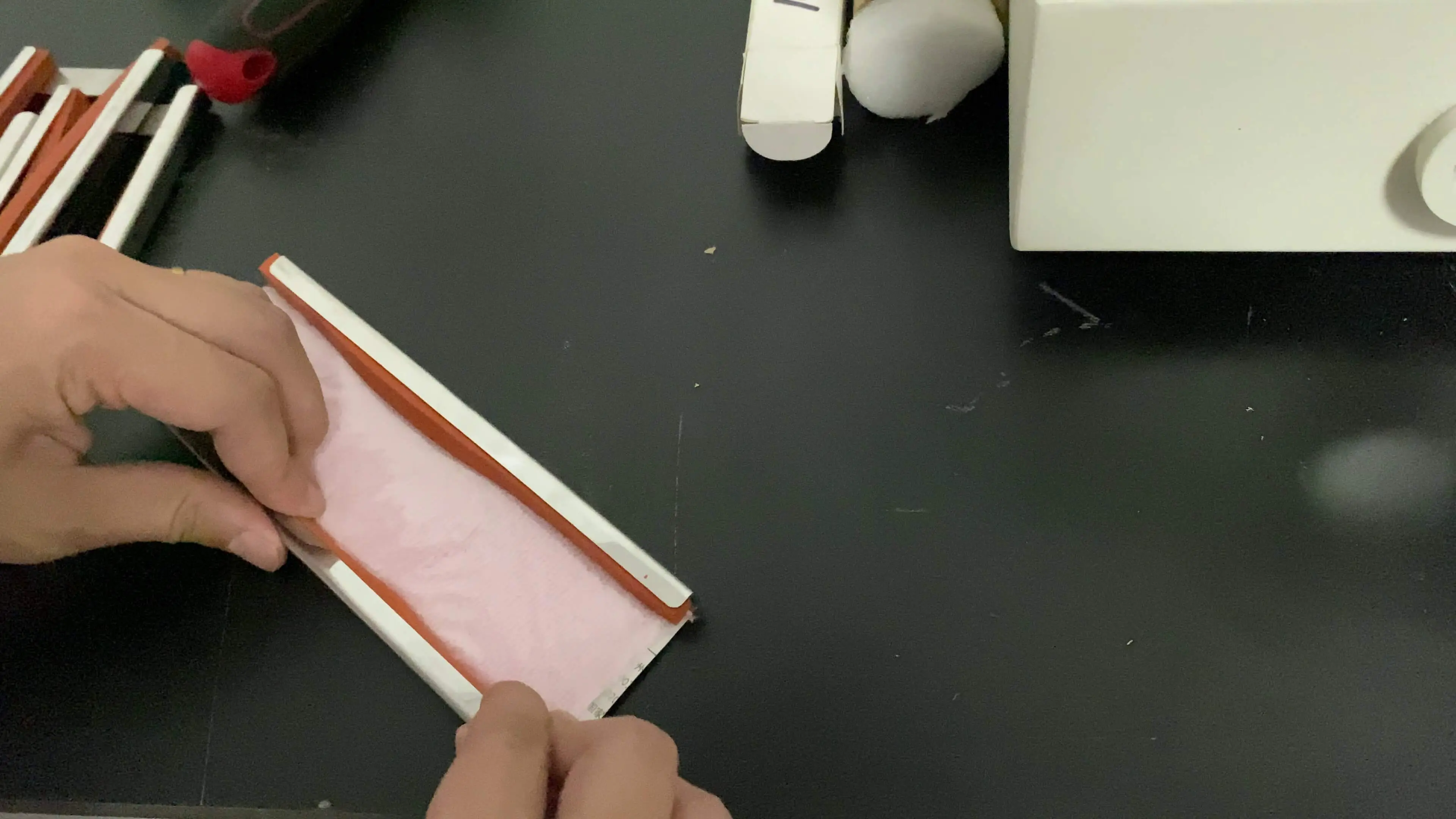

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home