- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

Small prototype of continuous hot melt rolling dyeing base D033

Overview

Application

Standards

Key Parameters

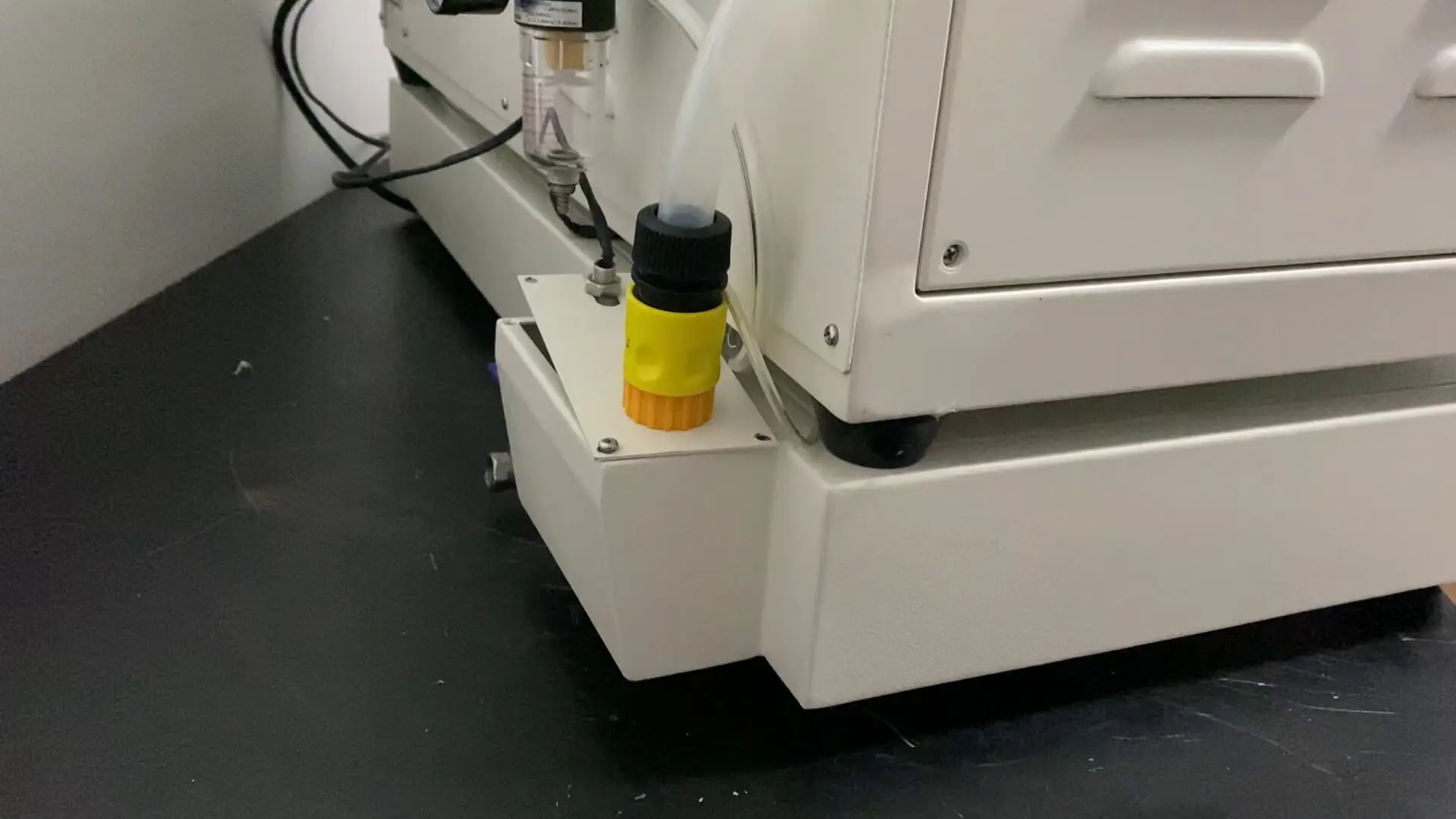

1. Rolling part

◆ the roll adopts high-precision butyl rubber, the length is 300, the diameter is ¢126.

◆ large-section film cylinder, anti-friction guide rail, automatic reset power failure, no left or right deviation, high reproducibility.

◆ roll pressure: 0.03-0.8mpa, stable pressure, easy to adjust.

◆ equipped with a set of four liquid tanks, each tank 150CC, easy to convert.

◆ equipped with safe foot switch.

◆ power: the voltage input is 380V/50HZ.One three-phase motor with 370W with reducer.

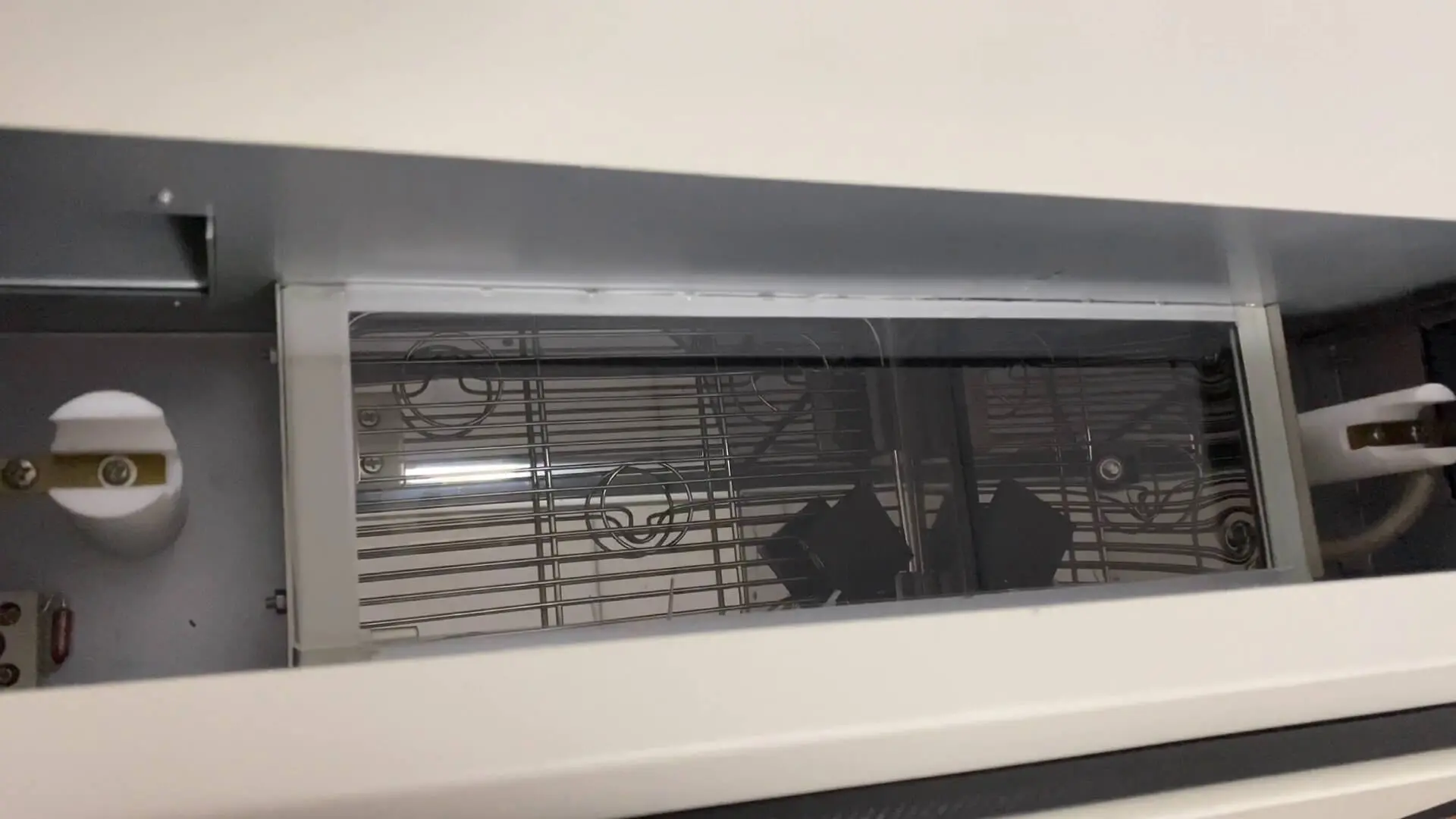

2. [infrared ray penetration]

◆ infrared penetration consists of 12 400W infrared heating tubes,

Uniform heat output, high heating efficiency.

◆ infrared work is divided into full load and half load.

◆ its input voltage is 220V/50HZ.

3. [pre-drying room and baking room]

◆ the hot air cycle is controlled by the quantity temperature control meter, and the control precision is ±1-2℃.

◆ the pre-drying working temperature is 20℃-150℃.

◆ the baking temperature is 20℃-240℃.

◆ the heating power is 9KW, the heating speed is fast.

◆ the cloth can be taken off automatically after preheating and baking, reliable and safe.

◆ the power of the preheating and baking fan is 0.75kw.Direct control of heating speed, frequency control.

◆ motor and control parts are made of high quality components with reliable performance and durability.

4. [complete machine]

◆ high quality SUS304 plate manufacturing.

◆ there is a set of control boxes.

◆ main drive is stainless steel chain and clip.

◆ motor frequency conversion speed regulation, arbitrary regulation.Easy to operate.The power is 0.75kw.

◆ each air compressor with a water spray gun.

◆ the power of the machine is 25KW, and the voltage input is 380V/50HZ.

◆ the machine weight is about 2500㎏.

◆ overall size: 3400 mm (length) ×1300 mm (width) ×3300 mm (height).

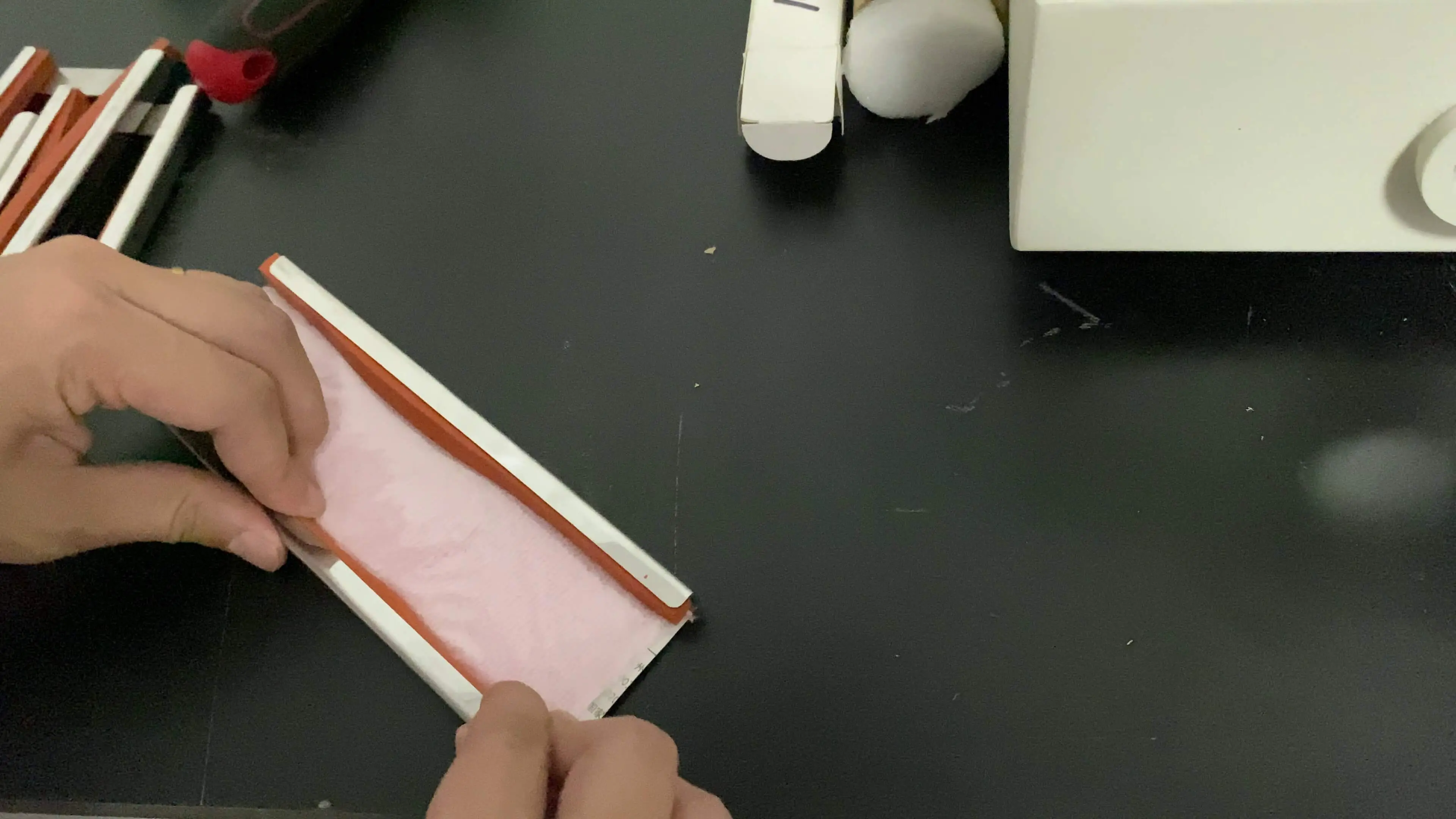

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Home

Home