|

1. Temperature

|

|

The temperature range

|

-20 ℃ ~ + 150 ℃ / -40℃ ~ + 150 ℃ / -70℃ ~ + 150 ℃

|

|

Temperature deviation

|

≦ ± 2.0 ℃

|

|

Temperature fluctuations

|

± 0.5 ℃

|

|

Temperature evenness

|

≦ 2.0 ℃

|

|

cooling rate

|

Heating rate: - 20 ℃ to + 100 ℃ about 35 min

(At no-load state, environmental temperature + 25 ℃)

Cooling rate: from + 20 ℃ to - 20 ℃ about 45 min

(At no-load state, environmental temperature + 25 ℃)

|

|

2. Humidity

|

|

Humidity range

|

20%R.H~98%R.H

|

|

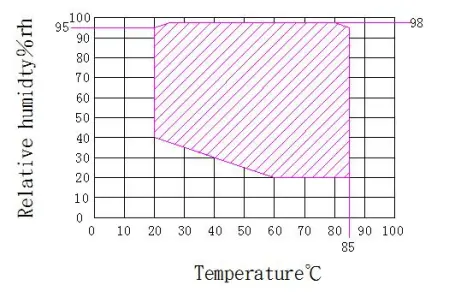

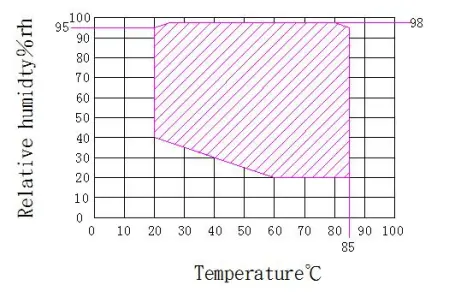

Temperature and humidity range

|

|

|

Humidity deviation

|

±3.0%RH(>75%RH)

±5.0%RH(≤75%RH)

|

|

Humidity uniformity

|

±3.0%RH (No load)

|

|

Humidity fluctuation

|

±2.0%RH

|

|

The temperature and humidity performance test is based on the relevant regulations of iec 60068-3 standard.The sensor is placed at the outlet of the unit.

|

|

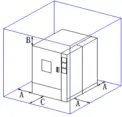

Chamber Structure

|

|

Consist

|

The test box adopts the whole structure form, that is, the test box consists of three parts: heat preservation box body, independent refrigeration unit and electric control cabinet

Composition.

|

|

Cabinet size

|

Inner box size: W 1000 x H 1000 x D 800 mm

Outer box size: W 1200 x H 2035 x D 1815mm (excluding machine stand)

|

|

Heat preservation box

|

External wall material: high quality carbon steel plate with electrostatic color spray treatment on the surface;

Inner wall material :SUS304# fog-faced stainless steel plate;

Insulation material: hard polyurethane foam insulation layer + glass fiber.

|

|

Chamber door

|

Single door, left open, add heating wire to the door frame to prevent condensation at the door frame at low temperature.

|

|

observation window

|

W 460 x H 560mm observation window is installed on the door of the box. Multi-layer hollow electrothermal coated glass can effectively keep warm and prevent condensation.

|

|

lighting device

|

LED lighting device, installed in Windows

|

|

Heater

|

High quality nickel-chrome wire electric heater, contactless control mode (SSR).

|

|

Humidifier

|

Water basin heating and humidifying method;

Stainless steel armor heater;

Heater control mode: contactless control mode (SSR);

Water level control device, heater dry - burning device.

|

|

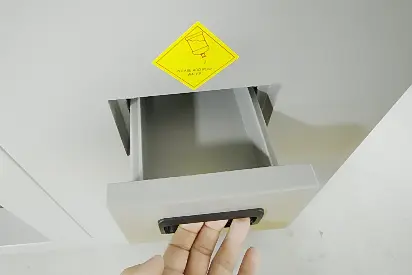

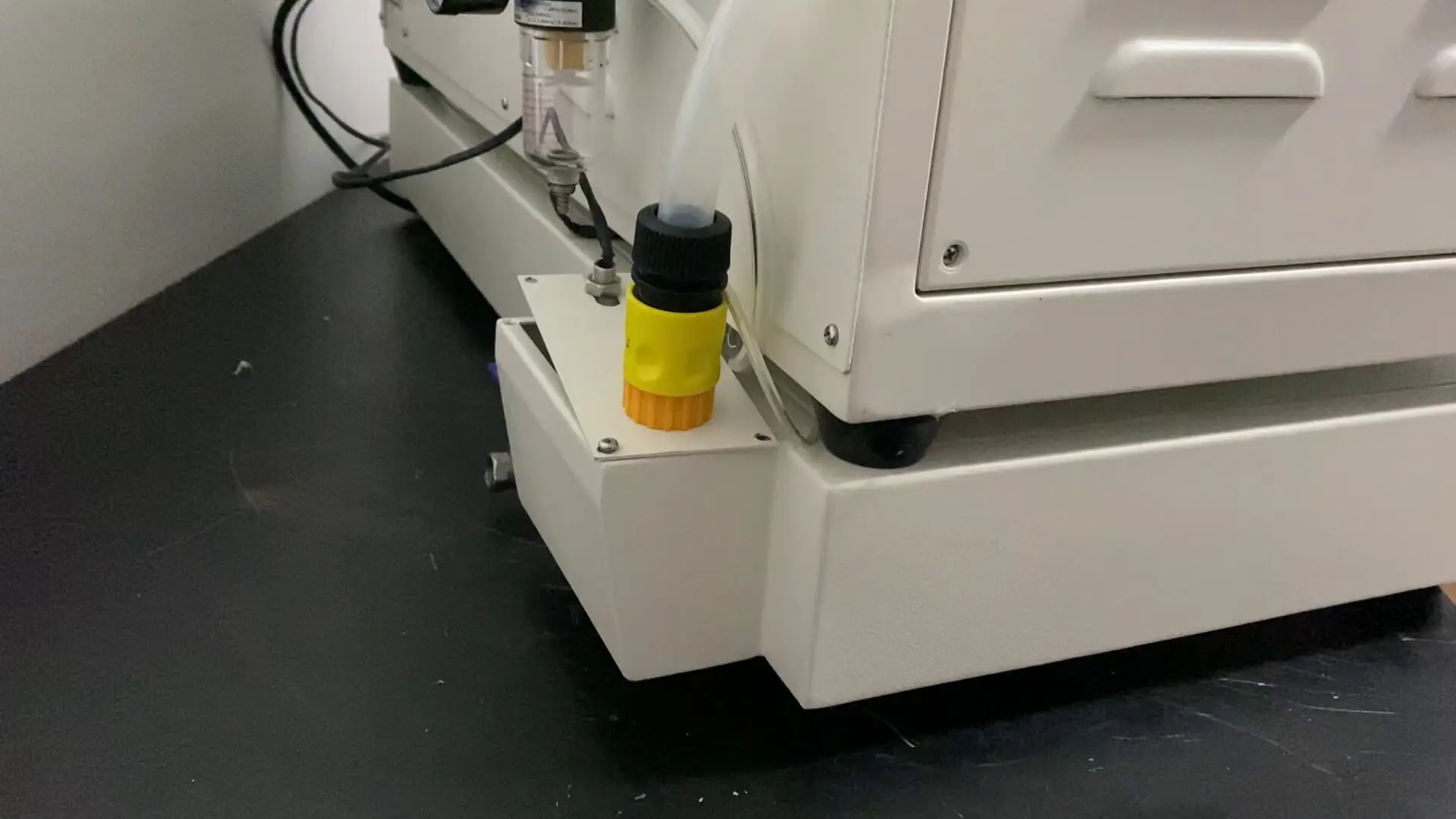

The condensate outlet hole

|

equipped with the studio condensate and the unit condensate drain hole.

|

|

Electrical outlet & cord hole

|

One for each side of left and right chamber, diameter 50mm, equipped with rubber isolation plug and rubber cover.

|

|

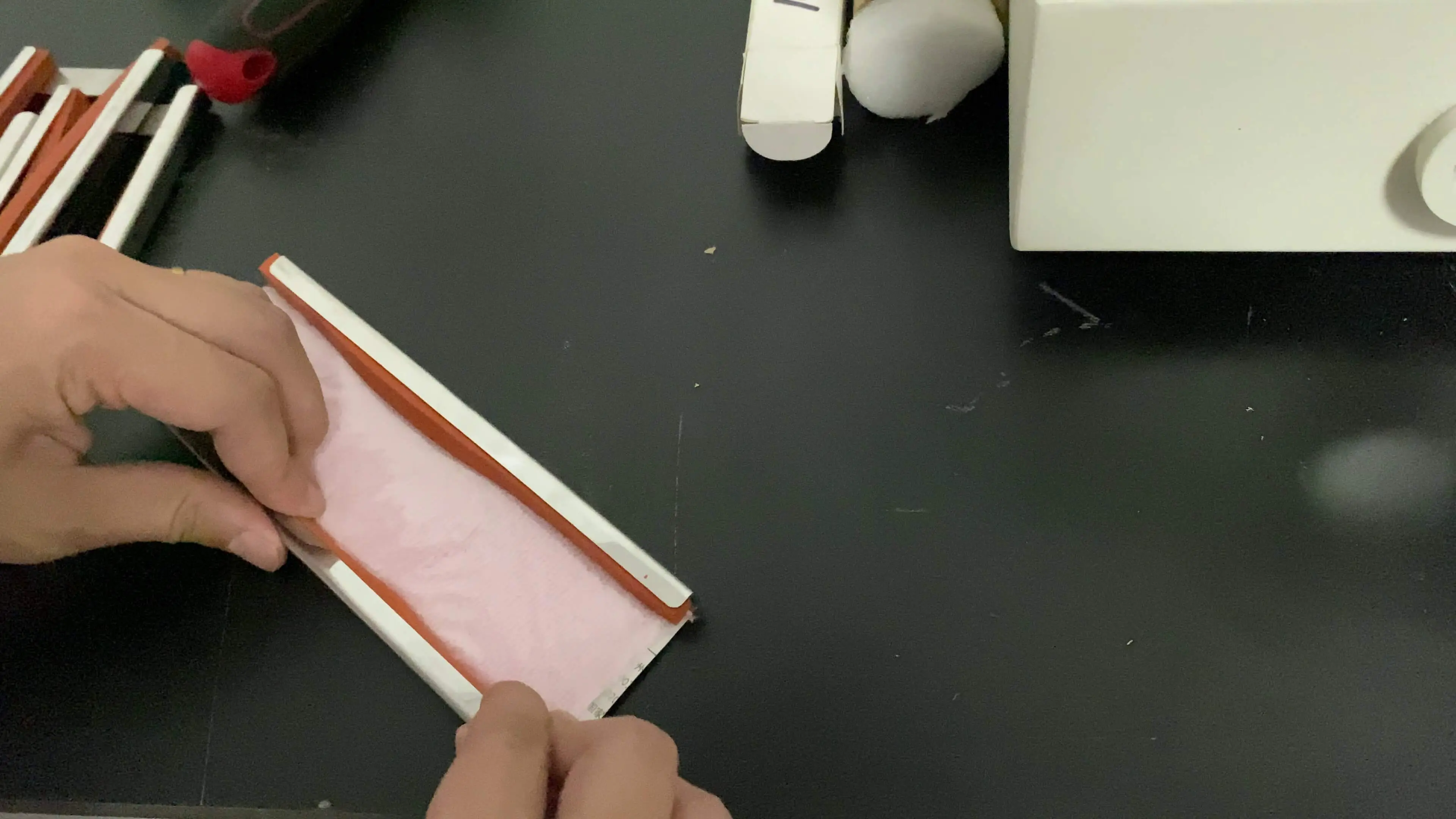

Sample frame

|

Two layers of stainless steel sample frame with adjustable height and carrying weight of 30kg/ layer.

|

|

Moving castor

|

Including moving castor

|

|

Power distribution control cabinet.

|

General power circuit breaker and overtemperature protector

|

|

Complement water system

|

Water pump provide automatic water supply

|

|

Refrigeration system

|

|

Working mode

|

mechanical compression and refrigeration.

|

|

Refrigeration compressor

|

original imported taikang full-density compressor from Europe and America.

|

|

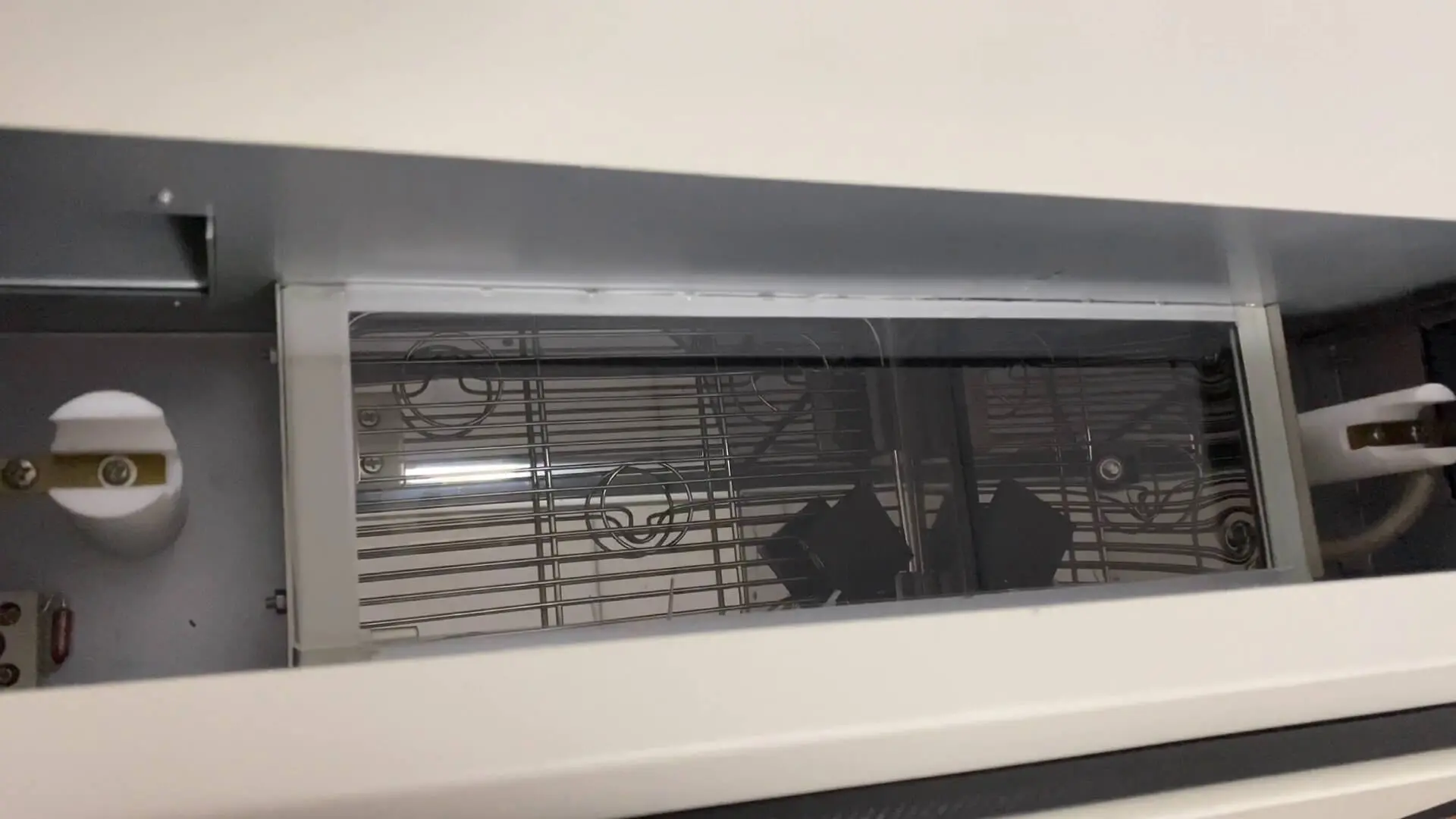

Evaporator

|

High performance fin automatic load capacity adjustment, can use low temperature and high humidity conditions for a long time without frost.

|

|

Condenser

|

Automatically dissipates heat and high efficiency flippers with a heat dissipation motor (air-cooled).

|

|

Refrigerant

|

Non-fluorine environmental protection refrigerant R404A, comply with environmental protection regulations, safe and non-toxic.

|

|

Other accessories

|

high-precision expansion valve, desiccant and other components are imported with original international famous brands.

|

|

Refrigerant flow control system

|

Automatically adjusts energy consumption output control.

|

|

Refrigeratory technology

|

l Fully implement nitrogen protection welding, double stage rotary vane pump vacuum, ensure the internal cleaning and reliability of the refrigeration system;

l The bottom of the compressor is designed with a water pan. The condensate is discharged out of the box through the drain pipe behind the box.

|

|

Control System

|

|

Sensor

|

High precision DIN A class, dry bulb φ4.8 mm SUS 304 Ω # 304 PT.

|

|

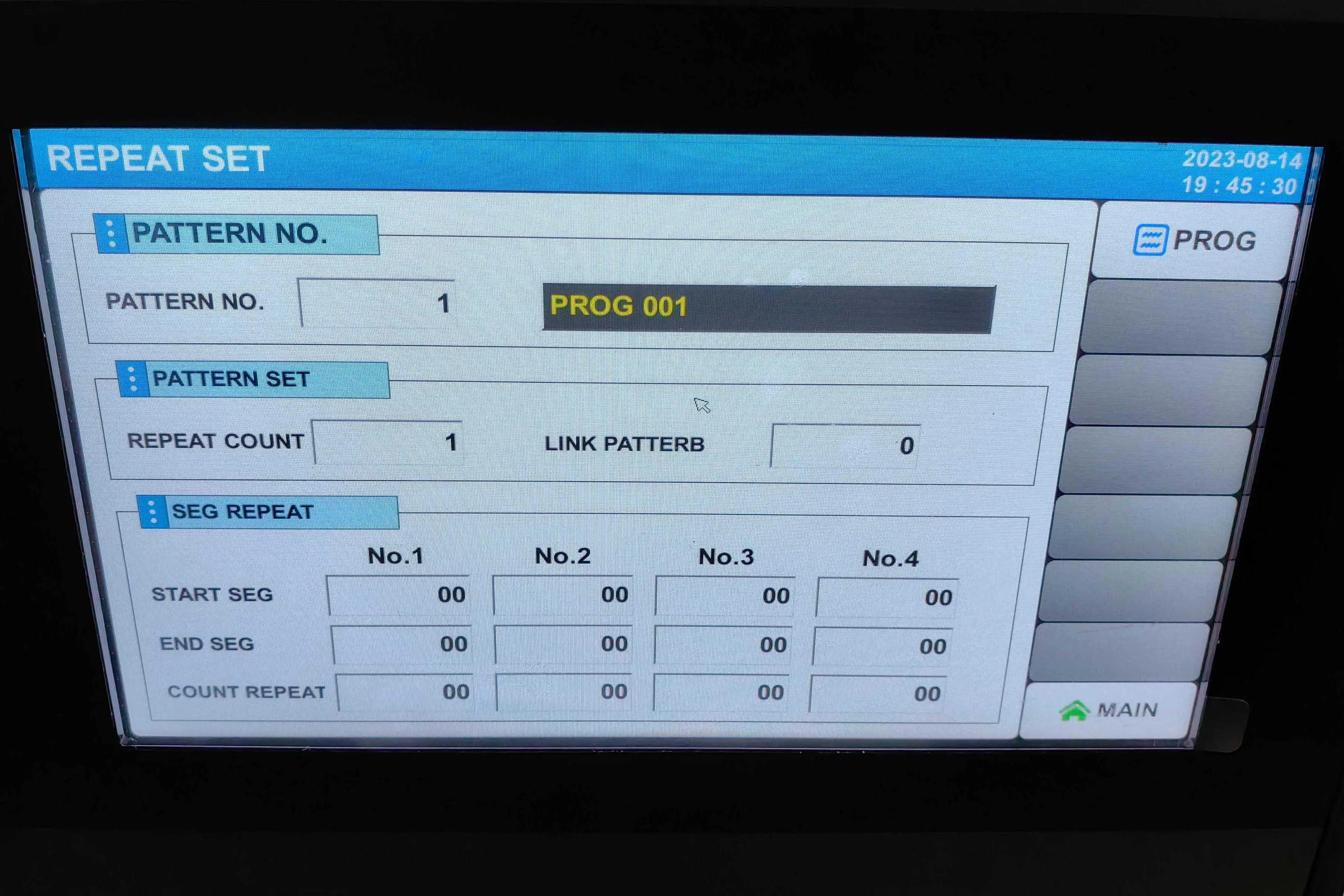

Controller

|

Programmable color LCD touch controller group PID control

|

|

Screen display function

|

l The actual (PV) value of temperature and humidity setting (SV) is displayed directly.

l The number, segment, remaining time and cycle times of the execution program can be displayed, and the running time can be displayed.

l Program editing and graphic curve display;

l Fixed point or program action status display;

l 7 "resolution :800*480, 65535 true color,LED backlight display screen.

|

|

Temperature control resolution

|

+ 0.01 ℃;Humidity: + 0.1%;Time: 0.01min.

|

|

Setting range

|

Temperature conditions: - 100 ~ 200 ℃;

Adjusted according to the temperature of the equipment working range lower limit (maximum + 5 ℃, - 5 ℃);

Humidity conditions :0 ~ 100 %RH.

|

|

Mode of operation

|

Program run, run at fixed value

|

|

Process capacity

|

The fixed running time can be set up to 999999 h 59m (or continuous running without time limit);

Usable program capacity: maximum 269 groups, 13450 sections;

Usable memory capacity: 50 segments per group (step);

Repeatable command execution: each command can run up to 32,000 cycles.

|

|

Setting mode

|

human - machine dialogue mode, using touch input, control.

|

|

Communication interface

|

Can connect the computer display curve, data collection;

Can be used as monitoring and remote control system;

Can do multiple machine synchronization control;

Rs-232, rs-485 and Ethernet.

|

|

U-Disk Memory Card

|

Can plug in 1g-8g disk to download the history curve, historical data, can hot plug and pull function.

|

|

Data recording mode

|

With battery protected RAM, it can save the set value, sampling value and sampling time of the device.

The curve recording period can be set as 30 ~ 300 SEC, and the maximum memory time can be stored continuously for 90 days. Historical data (when the sampling time is 1min) can be stored continuously for 10 years if it is not used continuously.

|

|

Power off memory function

|

The power failure recovery mode can be set as: hot start/cold start/stop.

|

|

Appointment starting function

|

The starting time can be set at will. After power on, the time will run automatically to the machine platform.

|

|

Software using environment

|

Windows xp in simplified Chinese/English or Windows 7/WIN8 in simplified Chinese/English.

|

|

Network connection

|

It can be connected to Ethernet by professional software, and can be used for remote control and remote assistance through the network. It can also collect test data through the network and control multiple machines at the same time.

|

|

Electrical apparatus control system

|

|

Control Panel

|

A. Emergency stop switch

B. Power switch

C. Overtemperature protector

D.R S - 485 interface

|

|

Safety Protective Device

|

A. heater air burn protection switch

B. Humidifier air burn protection switch

C. heater overcurrent circuit breaker

D. humidifier over-current circuit breaker

E. Overcurrent overload protection of circulating fan

F. Compressor high voltage protection switch

G. Compressor overheat protection switch

H. Compressor overcurrent protection switch

I. Overvoltage under-invert protection switch

J. Circuit breaker

K. Leakage switch

L. Low water level protection of humidifier

M. Low water level warning of water tank

N. Fluid power controller over zero

|

|

Alarm indication

|

When the above protection occurs, the equipment stops running and gives an audible and visual alarm. At the same time, the fault location, causes and solutions are displayed on the instrument.

|

|

Installation and Using Environment

|

|

Surrounding environment

|

ensure the environment temperature range: 5 ~ 35 ℃.

|

|

Power supply

|

AC 3ψ4W 380V 50Hz (R, S, T, N add ground wire)(voltage fluctuation≦±10%)

|

|

Grounding protection

|

Grounding resistance ≦ 4 Ω.

|

|

NOTE

|

PS.1. The above power supply requirements shall be provided to the terminal of the machine control box, and the customer shall prepare a special non-fuse switch for the equipment.

2. Please confirm whether the machine can enter the door or the passage elevator, etc.

|

|

Installation

|

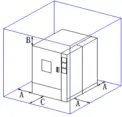

A: Not less than 60cm B: Not less than 60cm C: Not less than 120cm

|

|

Home

Home