- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Textile Laboratory Equipment Shoe Lining Leakproofness Tester ISO 20344 Shoe Waterproofness Tester H011

Overview

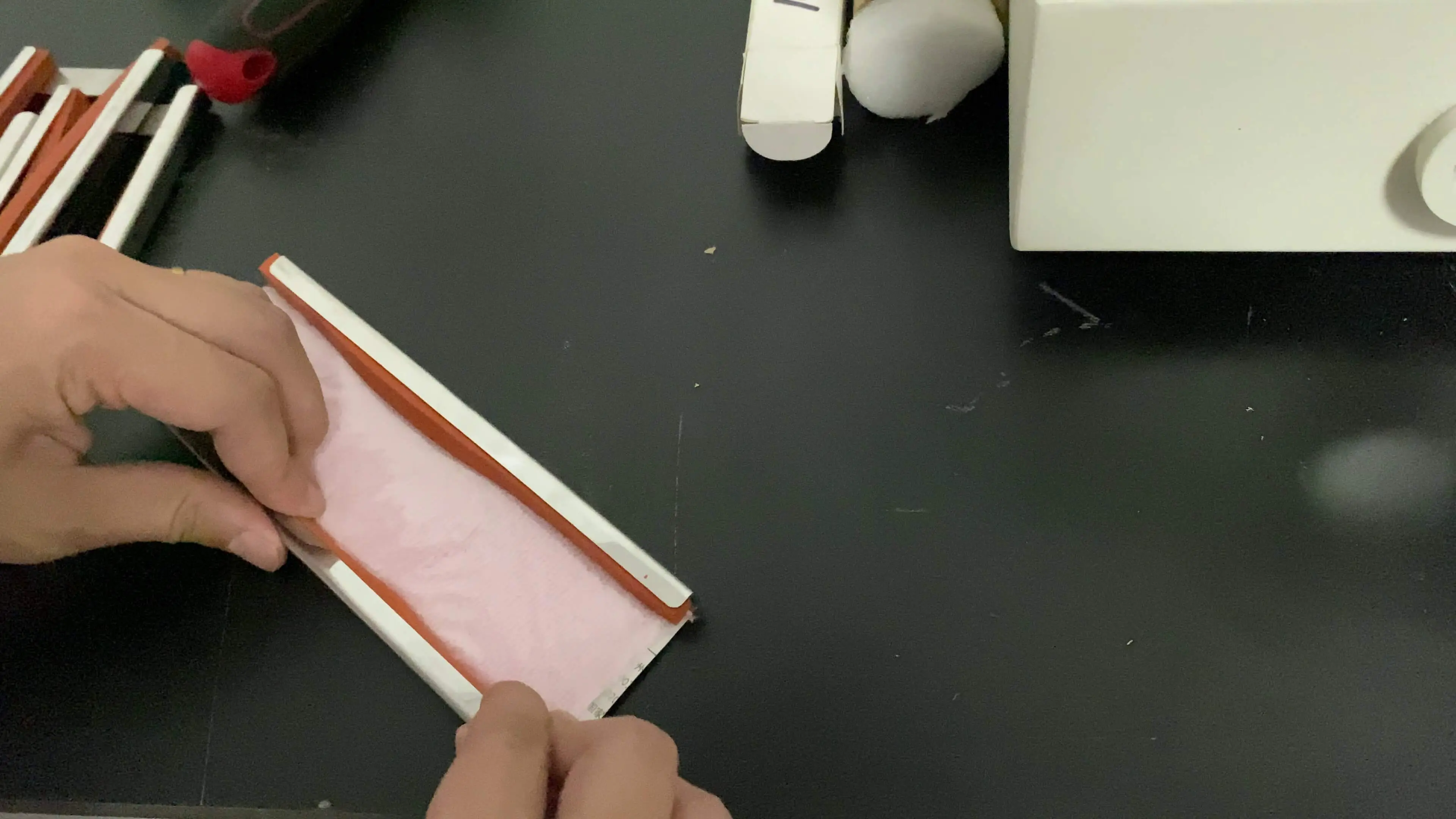

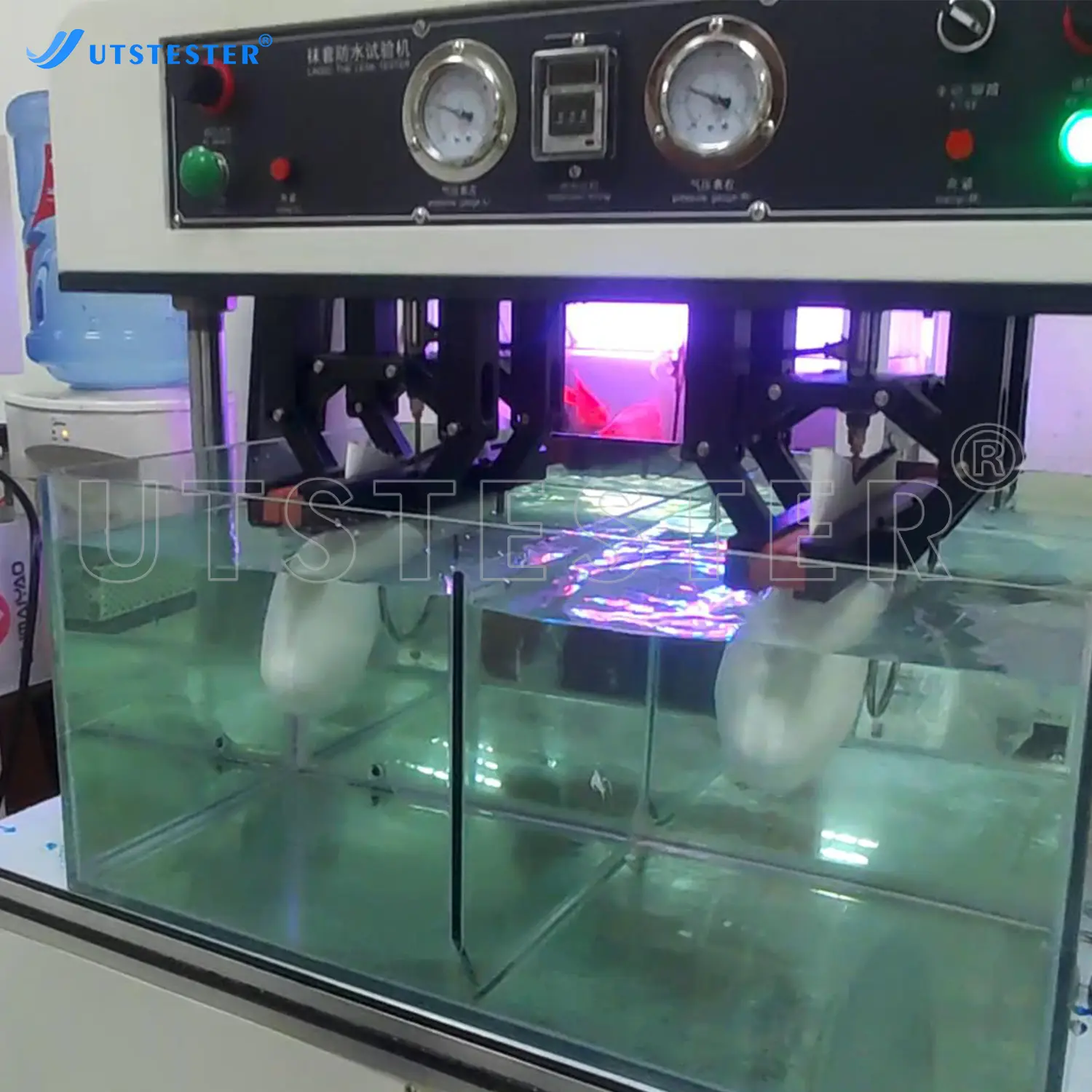

This machine is designed for determining the water permeability of all-purpose rubber overshoes9boots).this test is conducted based on the principle of water permeability .this machine can be used for testing your products in the production line so that you can fully control your production quality and improve your productivity.

This machine is to fill the air into the hose through the air compressor input compressed air, after the injection of air, the sample will be immersed in the water tank to the edge and apply (10± KPa) continuous internal pressure 30S, the hose will be pressed into the water tank to test the waterproof and leakproof.

Clamps are made of aluminum and SUS stainless steel to ensure no rust during long-term contact with water.

This equipment is tested at two stations at the same time, foot switch control descending, easy to operate, high efficiency, accurate test.

Application

Standards

GB/T 20991 section 5.7, ISO 20344 section 5.7,

AS/NZS 2210.2 section 5.7, ISO 8782-1, HG/T3664

Key Parameters

|

Model |

H011 |

|

Air pressure |

0.0~50kPa |

|

Accuracy |

0.1kpa |

|

Test Quantity |

2 pieces(4 pieces are also available) |

|

Clamp lifting stroke |

320mm |

|

Clamp surface |

220 mm |

|

Timer |

LED , 0-99999999 s |

|

Control mode |

Key or foot switch |

|

Air supply |

Above 4kg |

|

Power |

1∮﹐AC 220V﹐50Hz, 3A(Specified by user) |

|

Dimension (W x D x H) |

93*50*150cm |

|

Weight |

130kg |

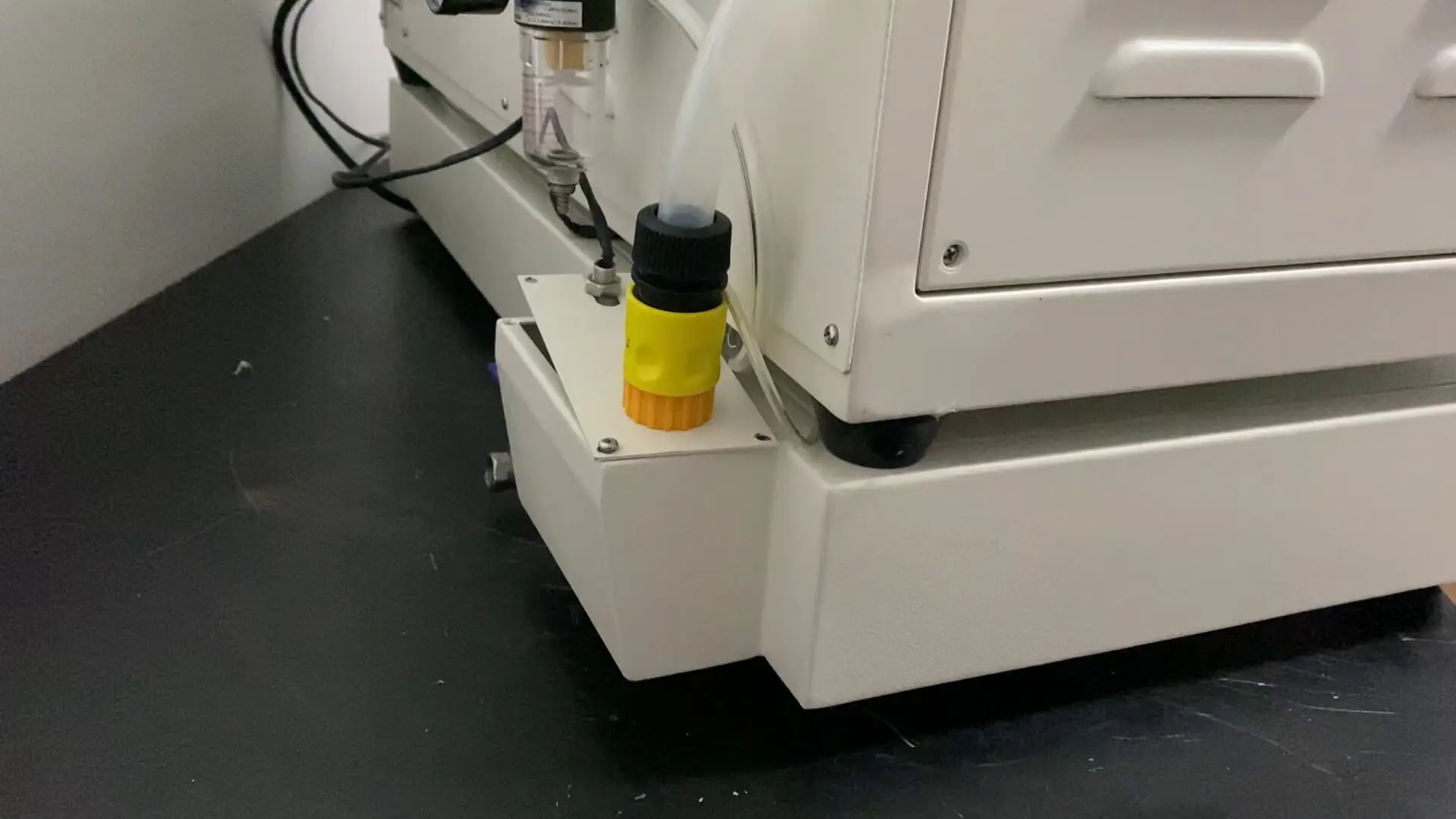

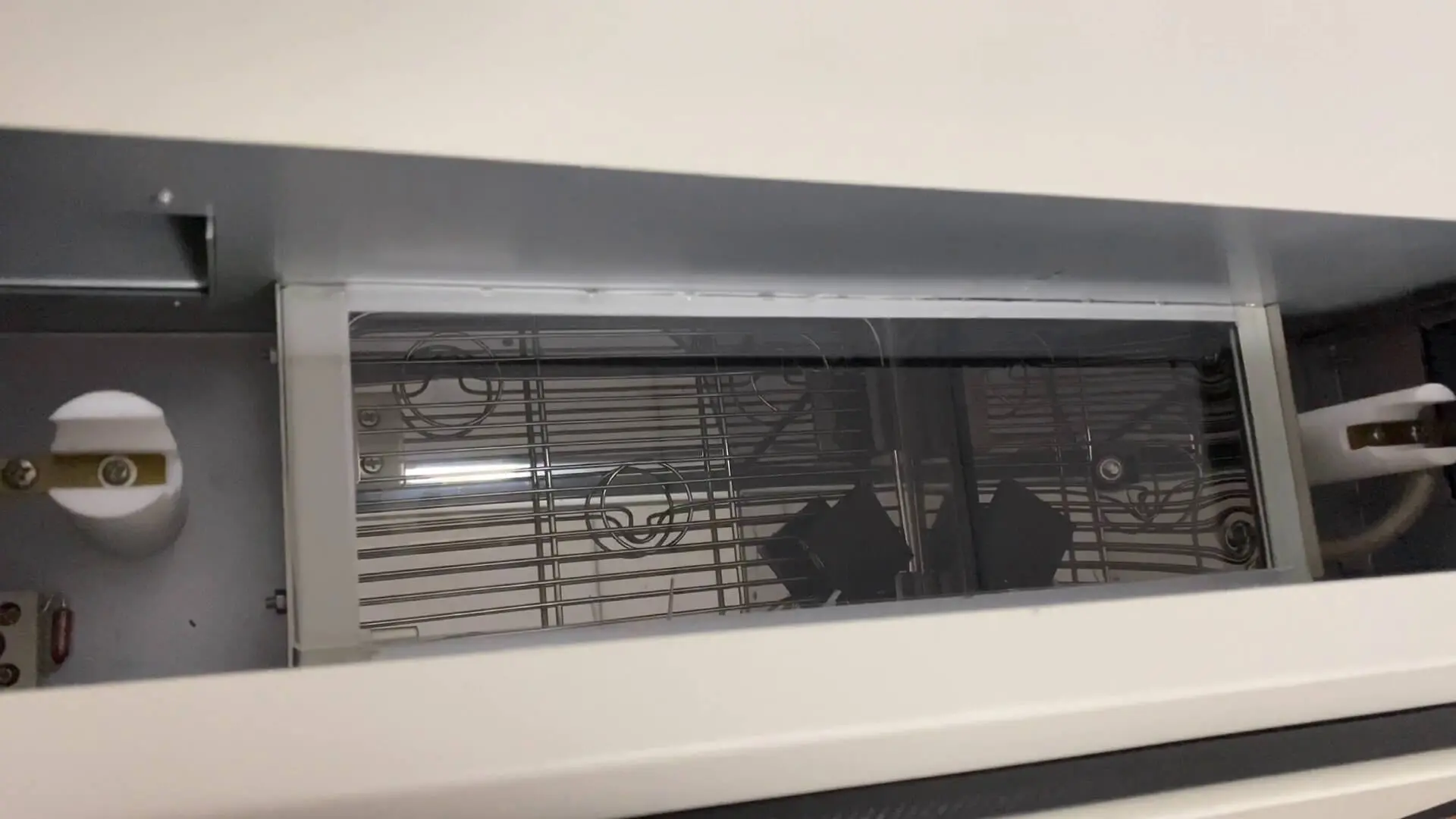

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home

![H011 Shoe Lining Lea[00-00-31][20240706-101140412]](/source/eb98230a276ece194d434b8a3e1738e2/h011-shoe-lining-lea-00-00-31-20240706-101140412.jpg)

![H011 Shoe Lining Lea[00-01-37][20240706-101335696]](/source/7fc64cb7ff38aa6aafd90d565527363a/h011-shoe-lining-lea-00-01-37-20240706-101335696.jpg)