- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

Textile Laboratory Equipment Vibration Knife Cutter M019 M019SMART

Overview

Application

Standards

Key Parameters

|

Model |

M018A |

|

Model |

M019SMART |

|

Technical parameter |

Specifications |

|

Effective cutting length * width |

1600*2500 |

|

Overall machine size |

3300*2450*1300mm (fixed table) 4050*2550* 1400mm (automatic feeding) |

|

Maximum cutting speed |

2000-4000mm/s (cutting speed varies with material) |

|

Repeat positioning accuracy |

±0.03mm |

|

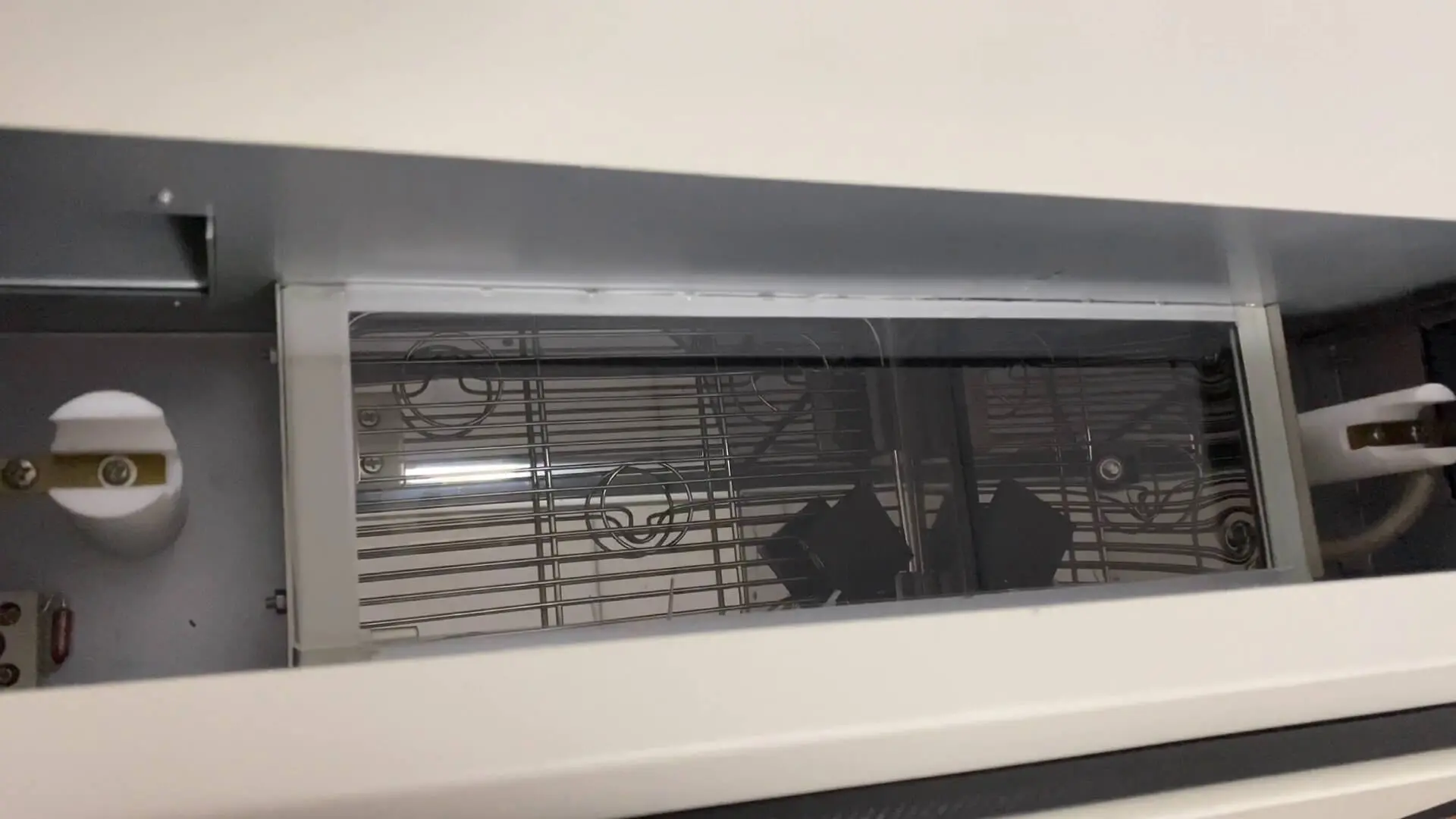

Adsorption method |

Vac-sorb |

|

Delivery method |

Automatic feeding/dressing |

|

Cut the countertop |

Import 4mm high strength felt |

|

Navar |

Liquid crystal touch control system, |

|

Driving mode |

Dong liang/Techtronix pure servo motor, li- near guide |

|

Reduction box |

1 A reducer |

|

Tool bit |

Vibration knife (optional according to fu- nction and material requirements) |

|

Skew gear tooth |

Precision helical gear |

|

Intelligent calcu- lation |

Computer intelligent automatic material discharge module, improve the utilization of materials |

|

Fault intelligent detection |

The machine automatically detects electri- cal faults and pushes the code to the system |

|

Cutting task mana- gement system |

You can view cutting tasks and completed tasks |

|

Joggle |

Internet Network port, USB (optional wire- less transmission) |

|

Safety device |

Infrared blocking stop and collision prot- ection |

|

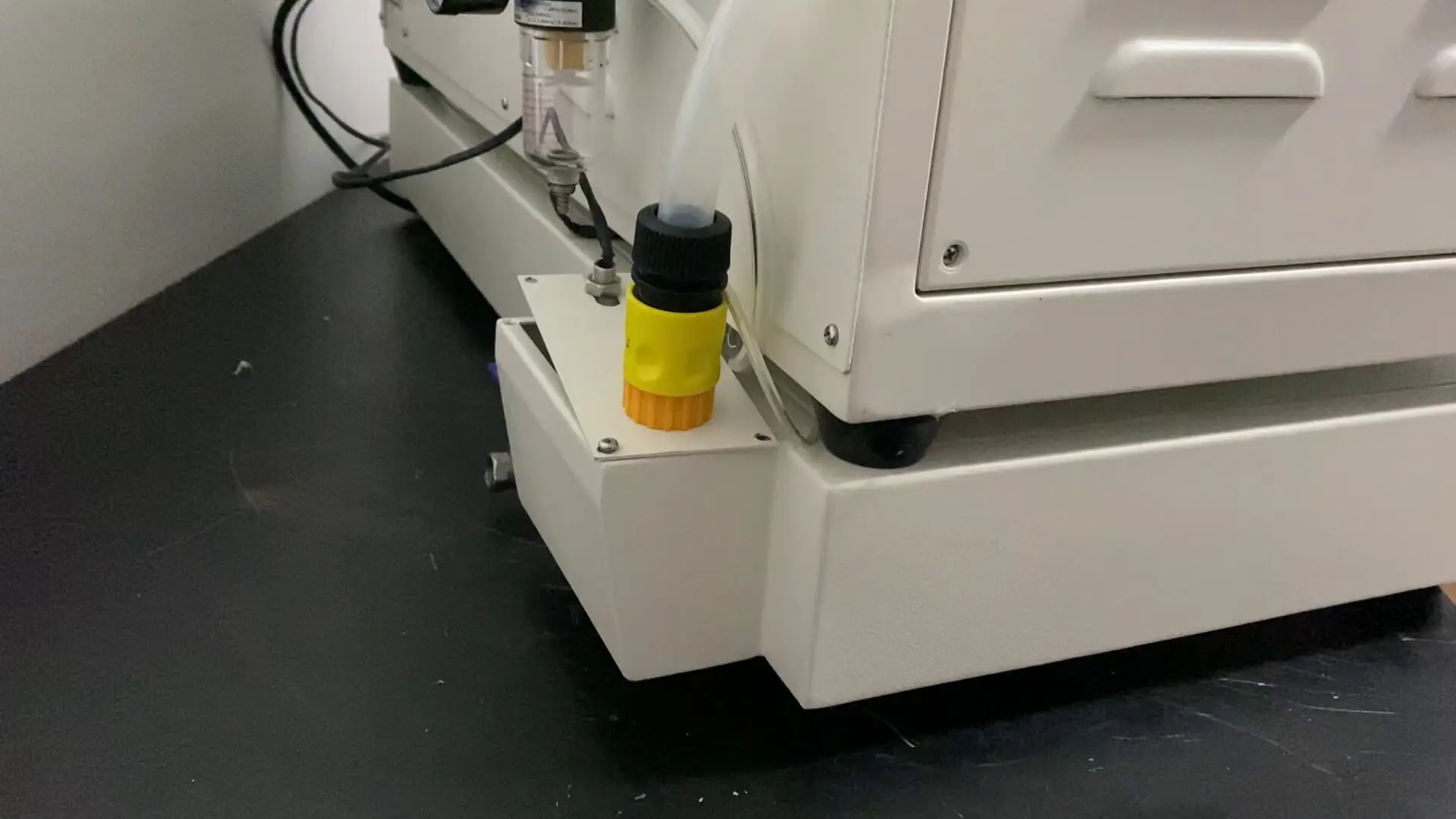

Air pump power |

7.5kw |

|

Frame construction |

Carbon dioxide protects the welding bed, secondary vibration aging treatment, 20 It doesn't change shape |

|

Cut the fabric |

Leather, silk ring, plastic, rubber, carp- et, sponge, PVC, footpad, corrugated paper, KT board, composite materials and other flexible materials |

|

Rated voltage |

380v/220v |

|

File support format |

AI, PLT, DXF, CDR, etc |

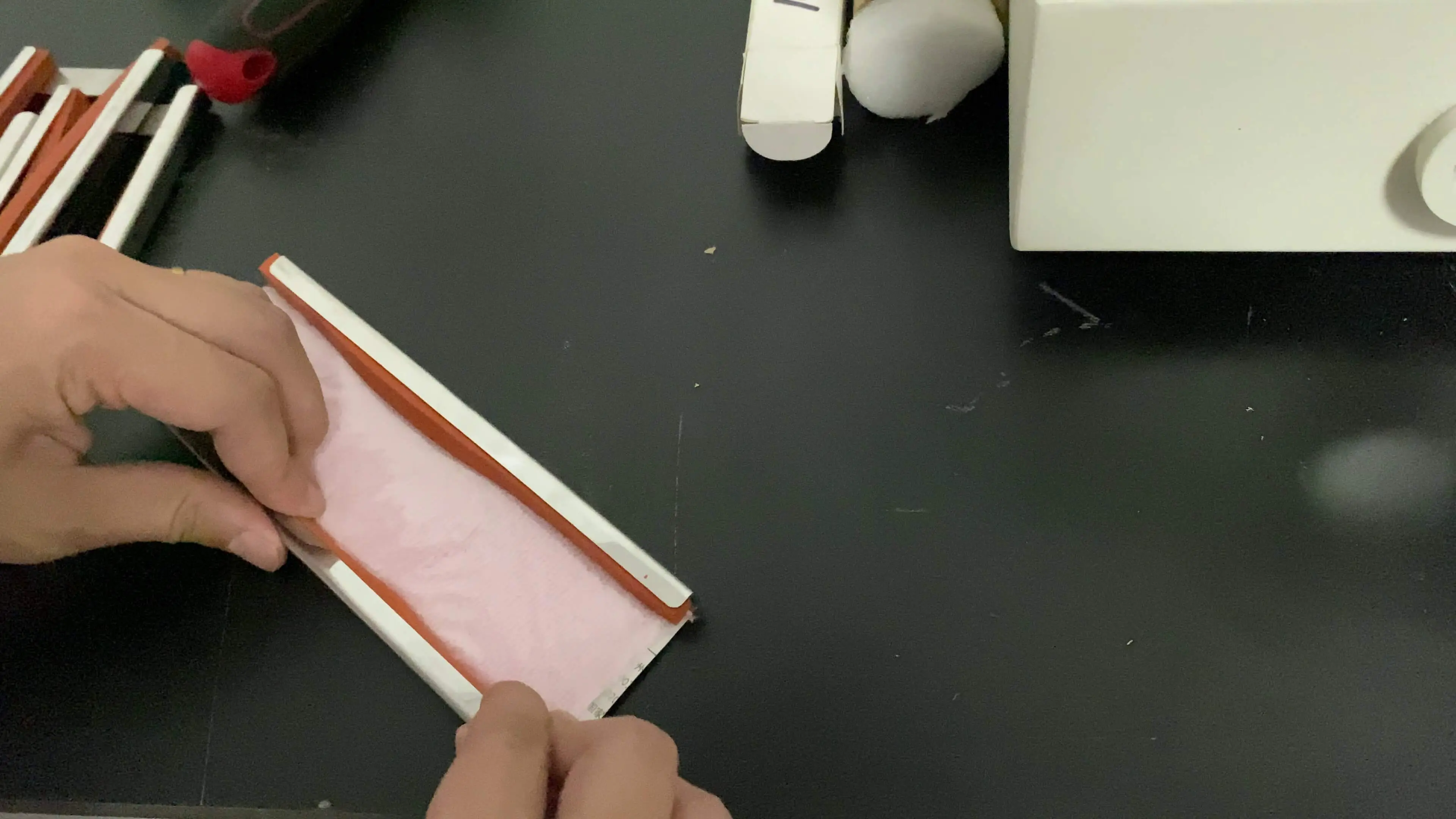

Control mode

Manual

Cutting area

100cm2

Cutting diameter

Φ112.8mm

Cutting thickness

5mm

Dimension

Φ160×115

Weight

1kg

Standards accessories

Schroder spare blades (Made in Germany) x 4pcs

Cutting mat x 1pc

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Home

Home