- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Textile Machinery Low Temp. Schildknecht Method Flexing Machine M104B-L

Overview

Flexing tests are sometimes required to be carried out at low temperatures below 0°C.

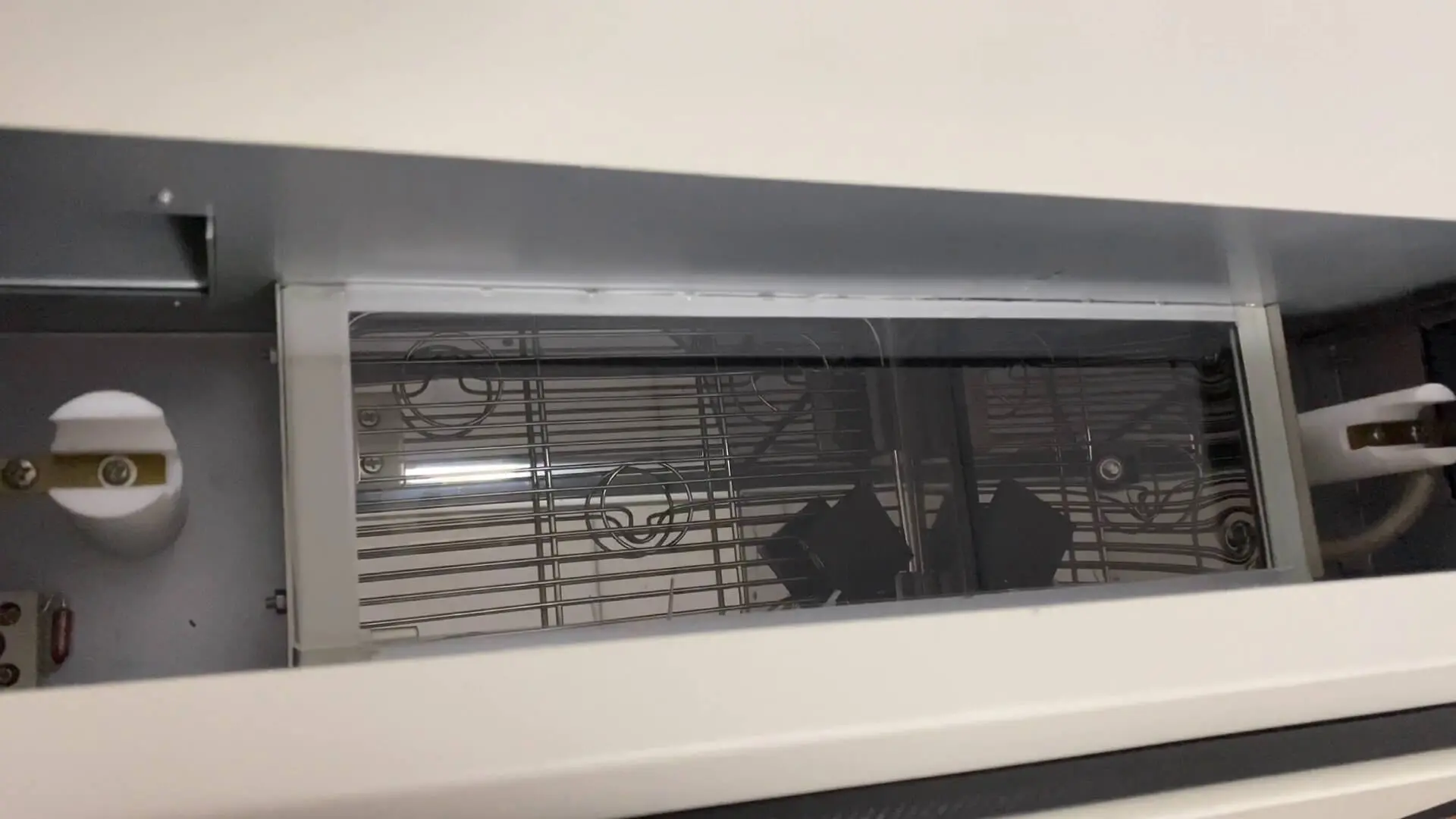

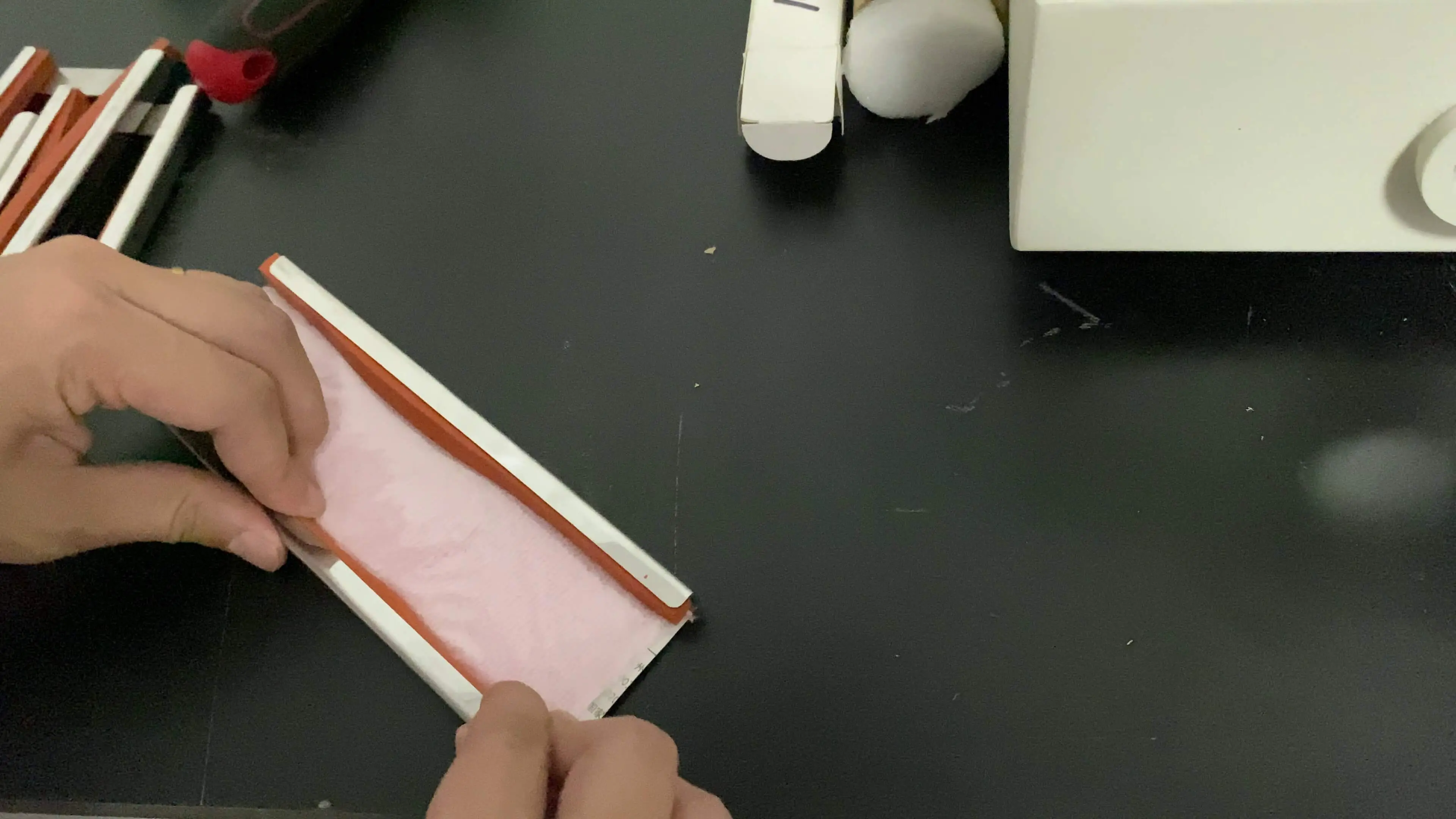

This low temperature version of the Schildknecht Method Flexing Machine is built into a low temperature cabinet. It is used for the flex testing of rubber or plastic-coated fabric to assess the effect of flexing under low temperature conditions. After repeatedly flexing and bending, check its degree of damage, crack and deterioration. It has 6 stations for small samples but can also accommodate larger samples by adjusting the mechanism.

Application

Standards

ISO 7854 Method B, BS 3424, GB/T 12586, EN14325 Part 4.6

Key Parameters

|

Model |

M0104B-L |

|

Test Chamber Volume |

150L |

|

Temperature range |

|

|

Test station |

6 test stations |

|

Fixture

|

6 group |

|

Speed

|

8.3Hz±0.4Hz(498±24r/min)

|

|

Cylinder |

External diameter Φ25.4mm±0.1mm |

|

Test track

|

arc R460mm |

|

Test stroke |

11.7mm±0.35mm |

|

Clamp |

Width 10mm±1mm |

|

Inner clamp distance |

36mm±1mm |

|

Sample size |

50mmx105mm

|

|

Sample quantity |

6 pieces, 3 pieces in warp direction and 3 pieces in weft direction

|

|

Count |

0~9999 times can be set |

|

Power Supply |

AC220V 50/60HZ 3A |

|

Dimension(W×D×H) |

105 x 140 x 100cm |

|

Weight (Approx) |

180 kg |

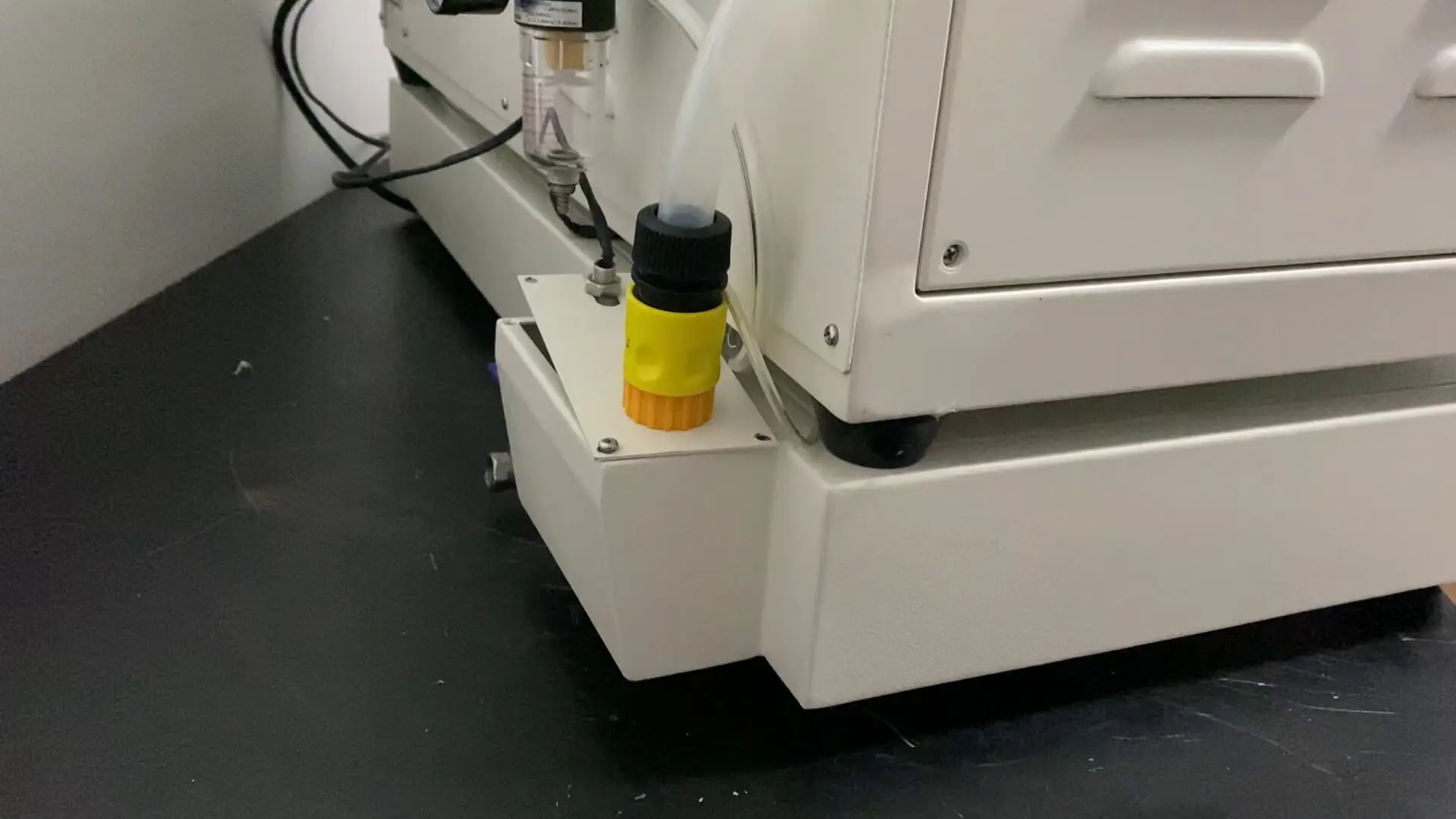

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home