- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

01020304

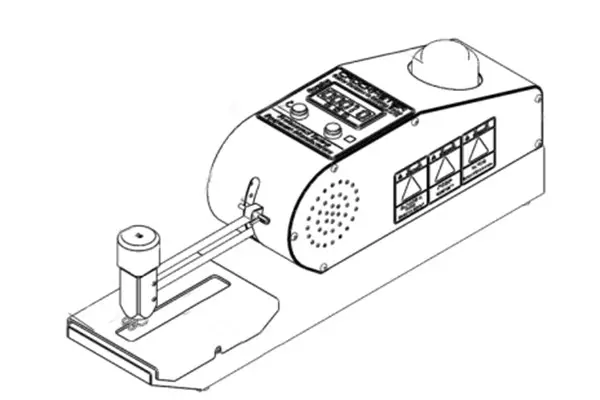

Textile Martindale Abrasion and Pilling Testing Machine

Overview

The Martindale is designed for multiple abrasion and pilling tests for various textile structures, including non-woven fabric, carpets, leather, socks, gloves, collars, cuffs, wood, high pressure laminates, painted surfaces, etc. The touch screen controller, with the most common functions accessible in one or two touches, makes this the easiest Martindale in the market to use.

4, 6, 8, 9 working positions and 2 counting Methods of count up & count down are available.

Application

Standards

Abrasion: ISO 12947, ASTM D4966, IWS TM 112, M﹠S P19, Next 18, SN 198529, TWC 112, JIS L1096, GB/T 21196.2, GB/T 13775

Pilling: ISO12945-2, ASTM D4970, IWS TM 196, M﹠S P17, Next TM26, SN 198525, GB/T 4802.2.

Key Parameters

| ITEM |

COMMENT |

| Model | M008A-4 |

| Working positions | 4 |

| Maximum stroke | Horizontal direction: 60 ±0.5mm Vertical direction: 24 ±0.5mm |

| Counting range | 0~999999 times |

| Pressurized material weight | A.Sample holder: 198 ±2 g B.Apparel fabric sample heavy bob: 395 ±2 g C.Furniture decoration sample heavy bob: 594 ±2 g D.B type sample holder: 155 ±1g E.Stainless steel disc: 260 ±1 g |

| Effective rubbing diameter | A type: 198g(1.96N) Abrasive head, diameter 28.65 ±0.05mm B type: 155g(1.52N) Abrasive head, diameter 90 ±0.10mm |

| Rotational speed | 50± 2r/min(20-70 r/min adjustable) |

| Sampling pressure hammer | 2385±10g |

| Power supply | AC 220V 50/60Hz |

| Dimensions(L x W x H) | 90×65×41cm |

| Weight | 150kg |

| Standard Environment Condition | 20±2℃ Related humidity: (65±5)% |

Product Details

Production Processes

Scenarios of Use

Operation (Abrasion Test)

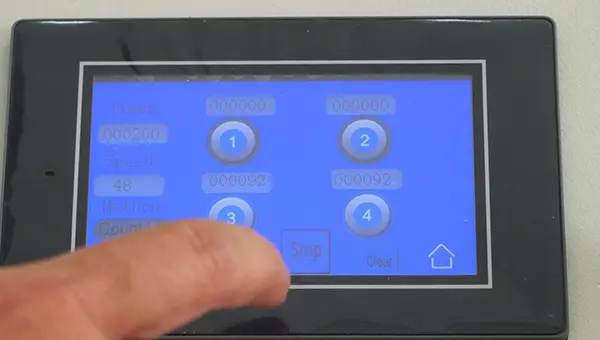

Set parameters

Turn on the power and enter the test interface.Set parameters according to standard requirements.

Place rubbing cloth

Place standard (140mm) wear-resistant cloth and felt on the test board,Press it down with a heavy hammer,Take out the bracket and rotate it to fix the friction cloth.

Install specimen

Place the cut sample and sponge pad into the grinding head,tighten the sample with the help of sample clamps.

Operation (Pilling Test )

Set parameters

Turn on the power and enter the test interface. Set parameters according to standard requirements.

Place rubbing cloth

Place standard (140mm) wear-resistant cloth and felt on the test board,Press it down with a heavy hammer,Take out the bracket and rotate it to fix the friction cloth.

Latch screw

During the pilling and pilling test, all three pin screws were put into the middle holes.

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home