- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Textile Testing Instruments Manufacturers Ici Mace Snag Tester M024C

Overview

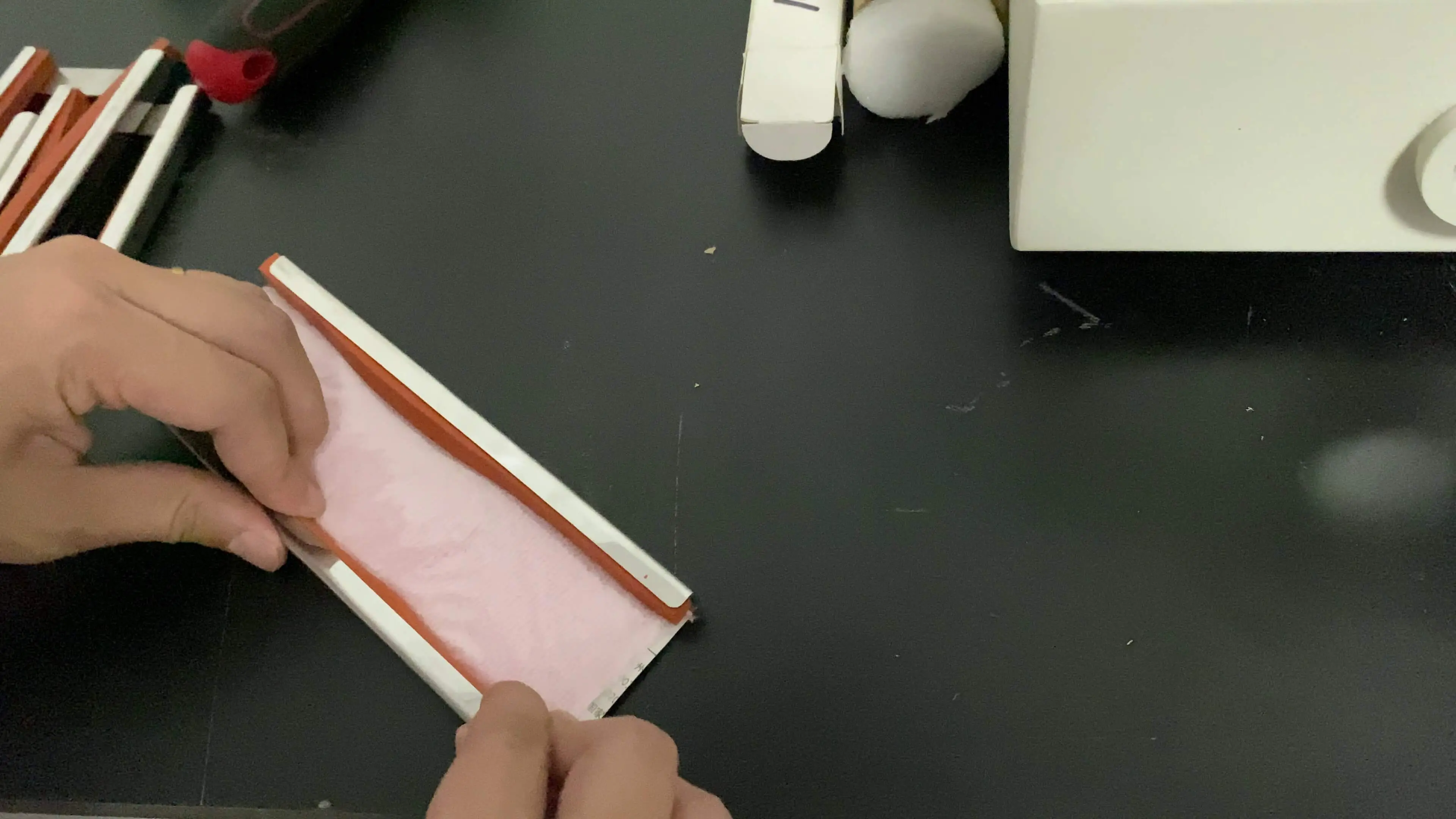

Used for evaluating the stitching degree of outerwear fabrics and other easily stitched fabrics, especially for chemical filament fabrics and textured yarns.

Application

Standards

GB/T 11047, ASTM D 3939

Key Parameters

|

Model |

M024C-2 |

M024C-4 |

|

Number of stations |

2 stations |

4 stations |

|

Drum speed |

60r/min, (40 ~ 80) r/min±2r/min adjustable |

|

|

Counting range |

0 ~ 99999 |

|

|

Drum diameter |

Φ82mm, width 210mm |

|

|

Hammer quality |

160±10g |

|

|

Number of needles planted with hammer |

11 |

|

|

Crochet exposed length |

10mm, tip radius: R0.13mm |

|

|

Felt thickness |

3 ~ 3.2mm, width: 165mm |

|

|

Guide rod working width |

125mm, diameter 10mm |

|

|

Distance between hammer and guide rod |

45mm |

|

|

Power source |

AC 220V 50HZ 100W |

|

|

Dimensions |

500×490×500mm |

500×490×860mm |

|

Weight |

58kg |

75kg |

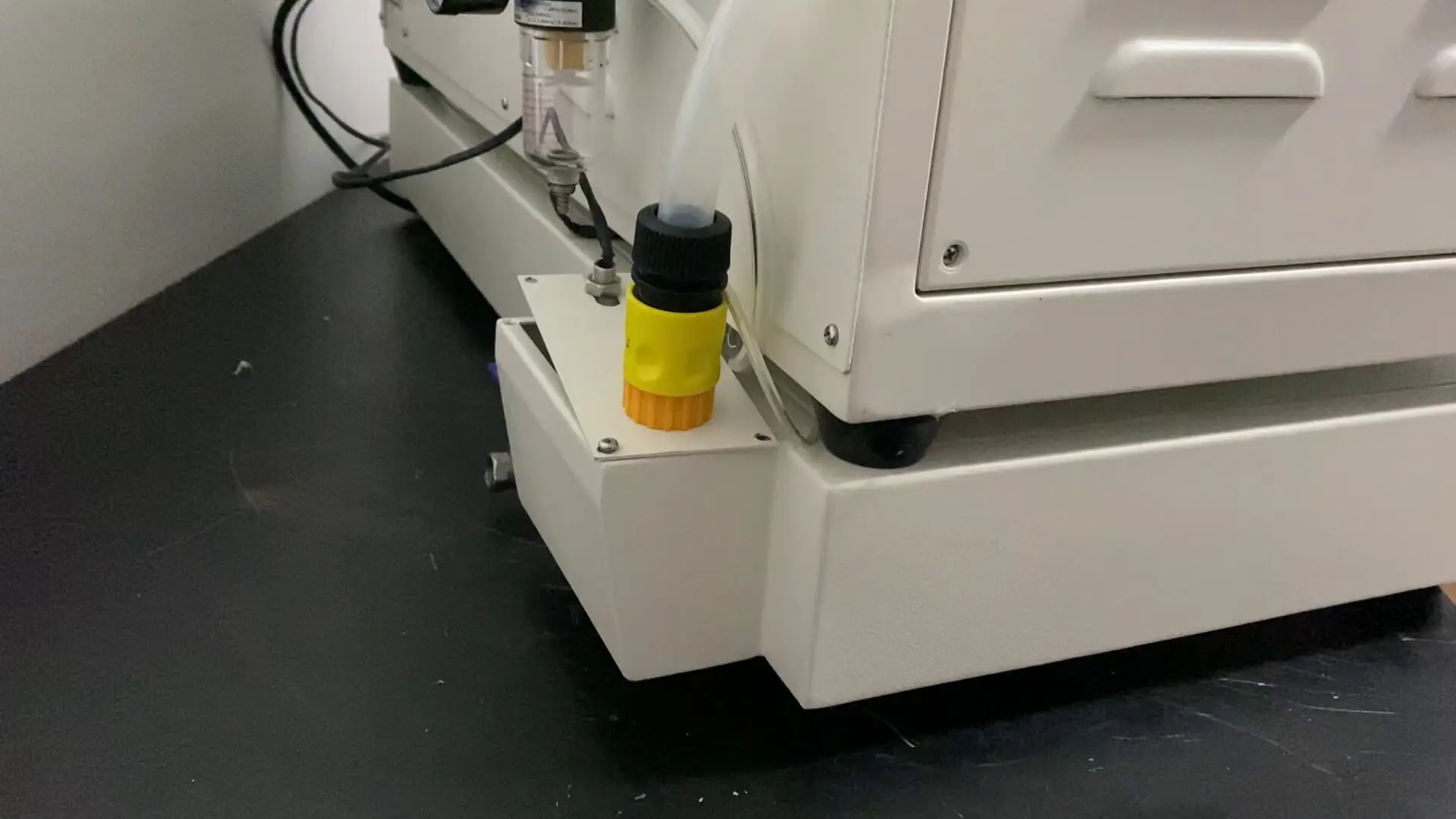

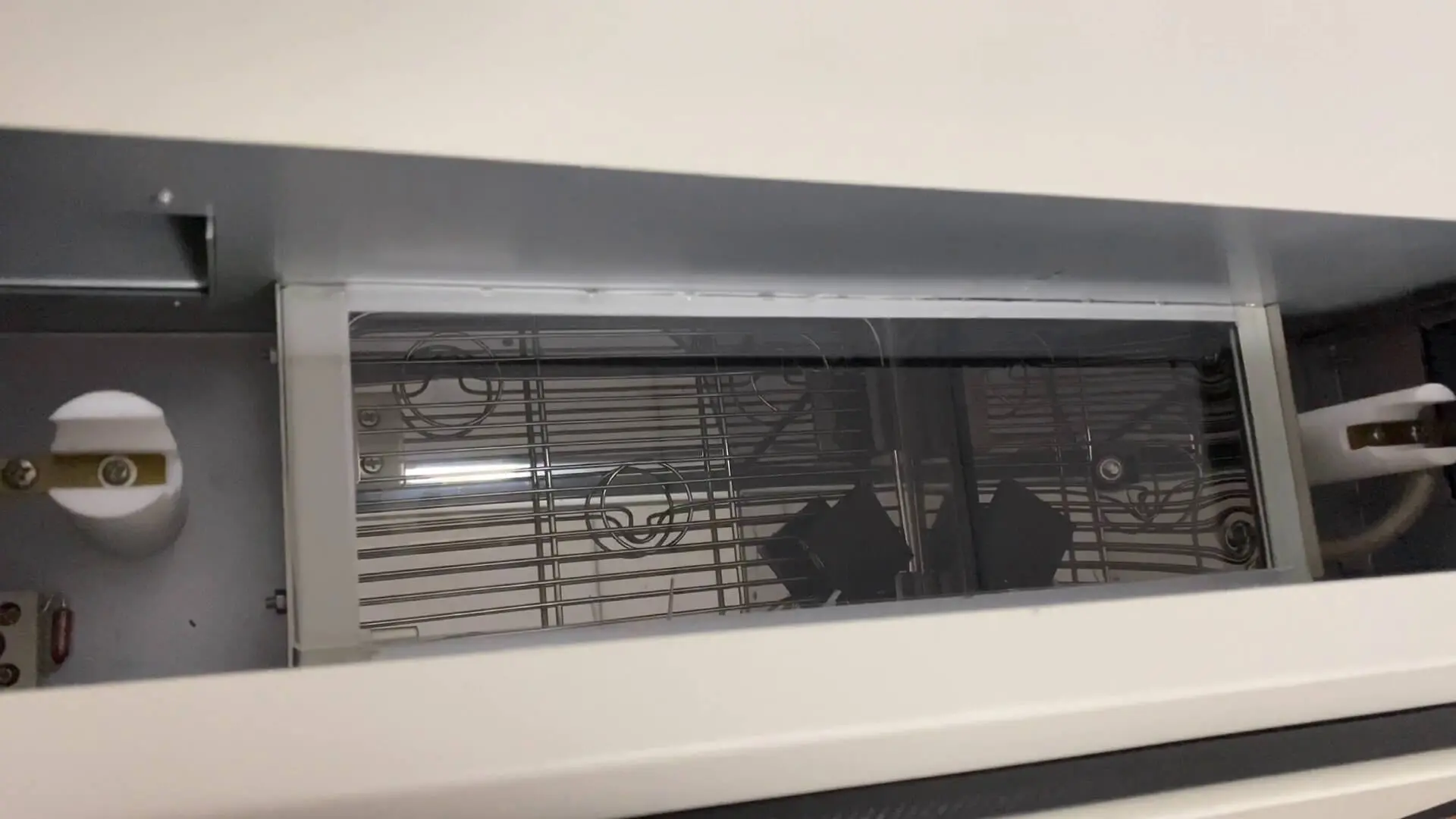

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home