- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

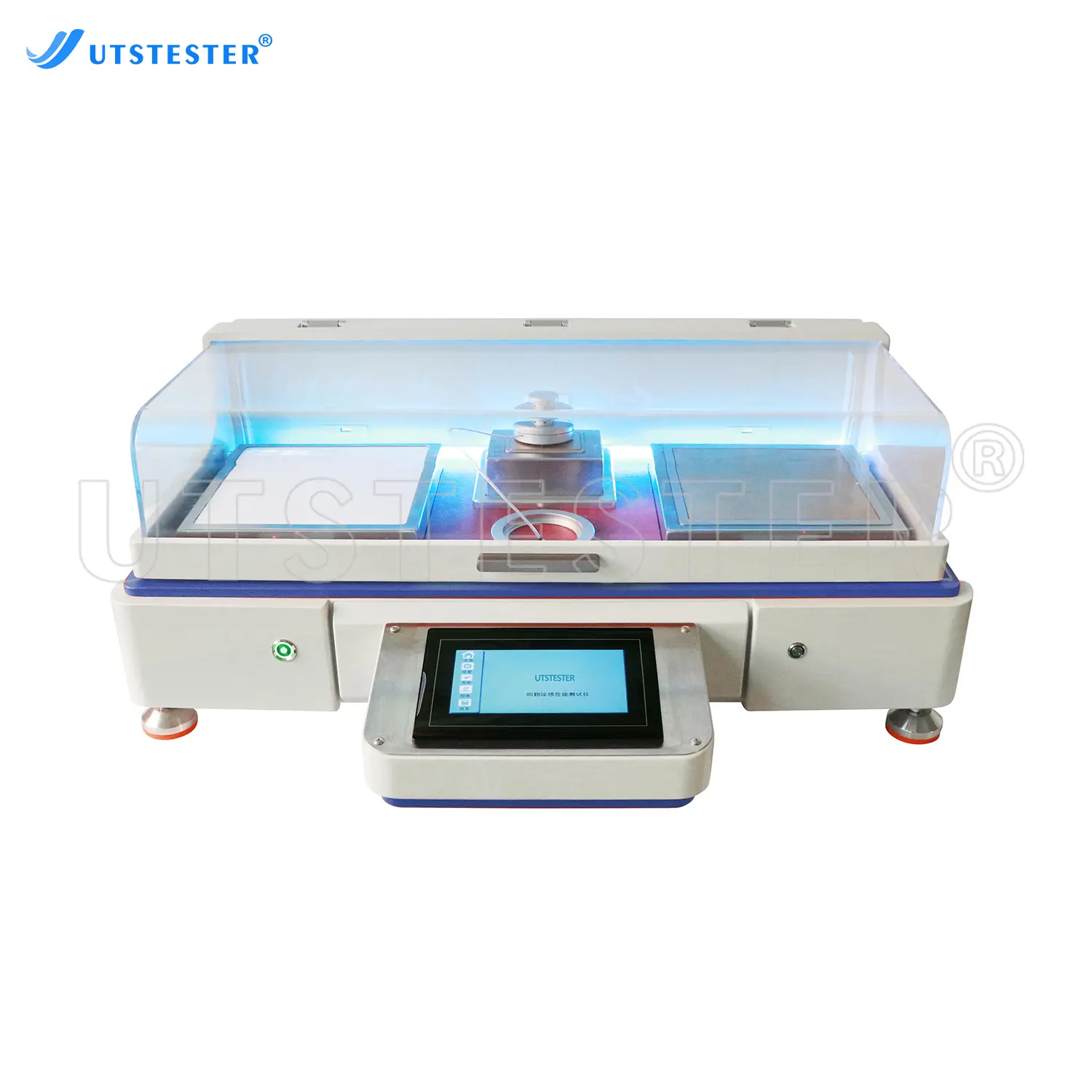

Textile Testing Machine Surface Coolness Tester JIS L 1927 M125-2

Overview

Fabric coolness performance tester is the fabric and human skin contact fabric to the skin temperature stimulation in the human brain formed on the judgment of cold and warm; when the fabric and skin contact instant, due to the existence of temperature difference, the fabric and the skin will occur between the heat exchange, so that the skin's temperature increases or decreases; the fabric and the skin between the form of heat exchange is mainly heat conduction, the fabric of the internal heat radiation and the influence of natural convection is very small, can be Normally (except the environment temperature is higher than the skin temperature), the skin temperature is higher than the environment temperature, so the fabric tends to decrease the skin temperature after contacting with the skin.

Used to test the coolness of pajamas, bedding, fabrics, and underwear.

Application

Standards

GB/T 35263-2017, FTTS-FA-019, FZT73067-2020, JIS L 1927

Key Parameters

|

Model |

M125-2 |

|

|

0.01℃ |

||

|

Test accuracy |

0.001J/(cm².s) |

|

|

Test time |

1~99s can be set |

|

|

Heating plate temperature range:room temperature |

+5--40°C |

|

|

Heat testing plate |

Area |

9cm², |

|

Pressure |

0.9±0.09N/cm² |

|

|

Test bench size |

220mm * 220 mm Heating platform size 200mm * 200 mm |

|

|

Electricity |

AC 220V 50Hz 200W |

|

|

External dimensions |

860 * 620 * 337mm |

|

|

Weight |

50kg |

|

Product Details

Production Processes

Scenarios of Use

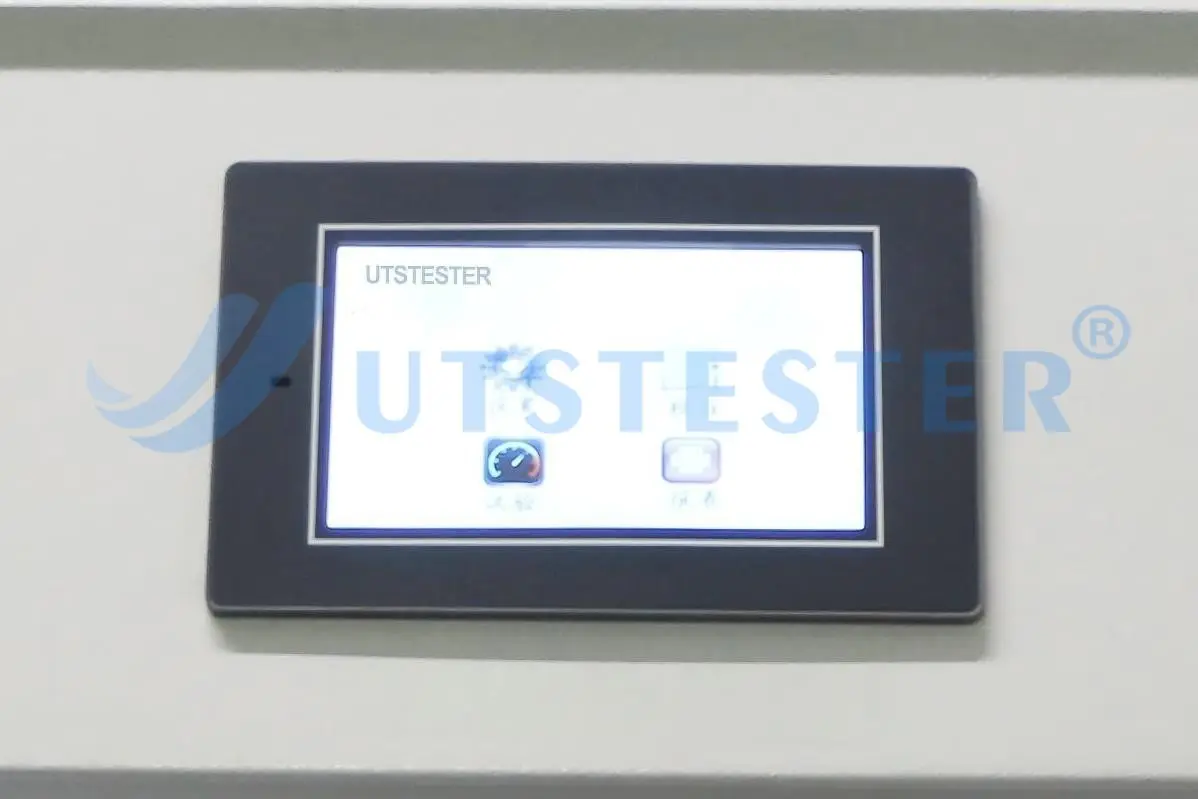

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home