- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

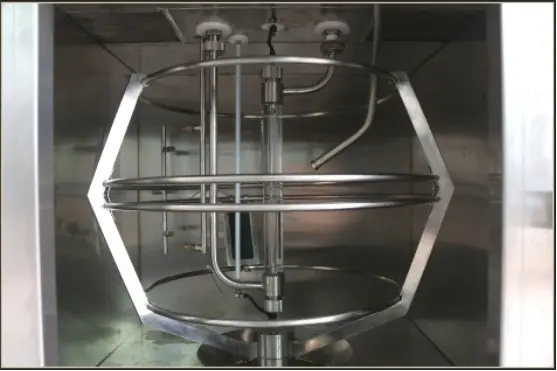

Textile Testing Machine Water Cooled Light Fastness Tester UTS-3000

Overview

Application

Standards

|

Textile |

GB/T 8430, GB/T 12831, GB/T 14576, GB/T 8427, GB/T 1189, GB/T 9344, GB/T 16422.1, GB/T 1865, GB/T 2423.24 ISO 105-B02/B04/B06, AATCC 169 |

|

Artificial board |

AATCC TM 16, ASTM G26, ASTM D2565, ASTM D4459, ASTM D 6695, ASTM G155, SAE J1885, SAE J2412, SAE J2212, SAE J1960, SAE J2527, AATCC 169 |

|

Automotive trim |

ISO 105, ASE J1884KJ, ISO 11341, ISO 4892, ISO 3917, ISO 11341, ISO 4892-2 |

|

Leather |

PV 1303, PV 3929, PV 3930, DVM 0067- MA, HES D6601, HES D6601, NES M0135, TSL 0601G, GMW3414, EDS-T-7415, D47 1431 |

Key Parameters

|

Model |

UTS-3000A |

UTS-3000B |

|

|

Water-cooled Long Xenon Arc Lamp Rated Power |

4500W |

6000W |

|

|

Exposure Area |

2660 cm2 |

4700 cm2 |

|

|

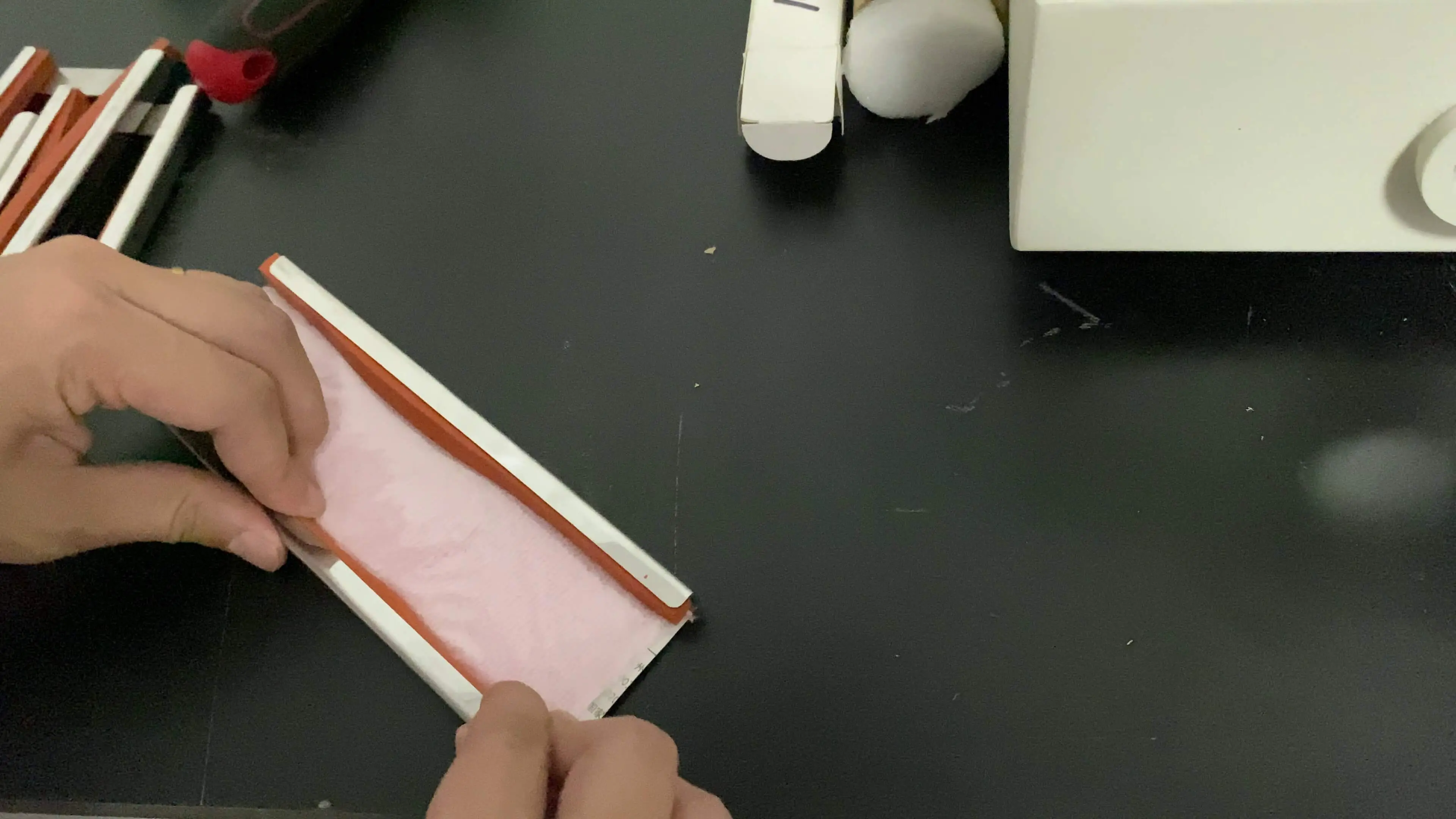

Sample Holders |

ISO:135×45mm 33pcs Or AATCC:100 ×75mm 20pcs |

ISO:135×45mm 47pcs Or AATCC:100 ×75mm 35pcs |

|

|

Test chamber temperature range |

20-93℃ ±1 ℃ Resolution: 0.1 ℃ |

||

|

Chamber Humidity Range

|

Light Cycle: 10-85%RH; Resolution :0.1%RH Dark Cycle: 30-100%RH; Resolution :0.1%RH |

||

|

BPT |

35-125 ℃, resolution 0.1 ℃ |

||

|

BST (Optional) |

35-120 ℃, resolution 0.1 ℃ |

||

|

Test time Control Range |

≦1000 hours |

||

|

Irradiance Control Range |

0.6~3.08W/m²@420nm (Option: 340nm, 420nm, 300-400nm and 280-800nm) Accuracy: ±0.02W/m²@420nm. Digital Set, Automatic Compensation |

||

|

Sample Tray Rotating Speed |

1-7rpm (Settable) |

||

|

Sample Tray Diameter |

Φ550mm |

||

|

Photoperiod |

≦1000 hours |

||

|

Spray cycle period |

≦1000 hours |

||

|

Power Supply |

AC 220V±10% 50Hz 10KW |

||

|

Dimensions |

1200 x 900 x 1800mm(L x W x H) |

||

|

Weight |

350kg |

360kg |

|

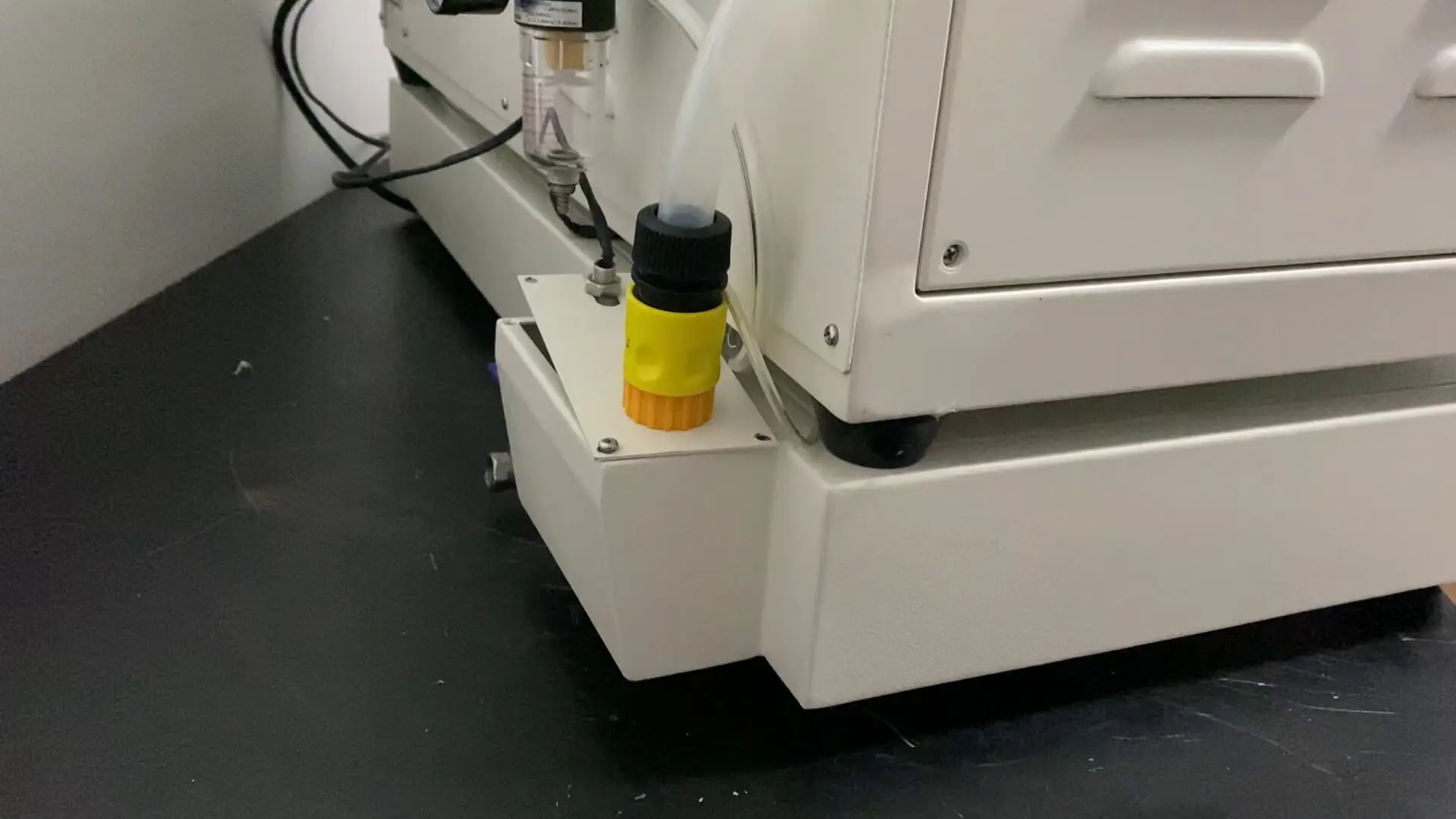

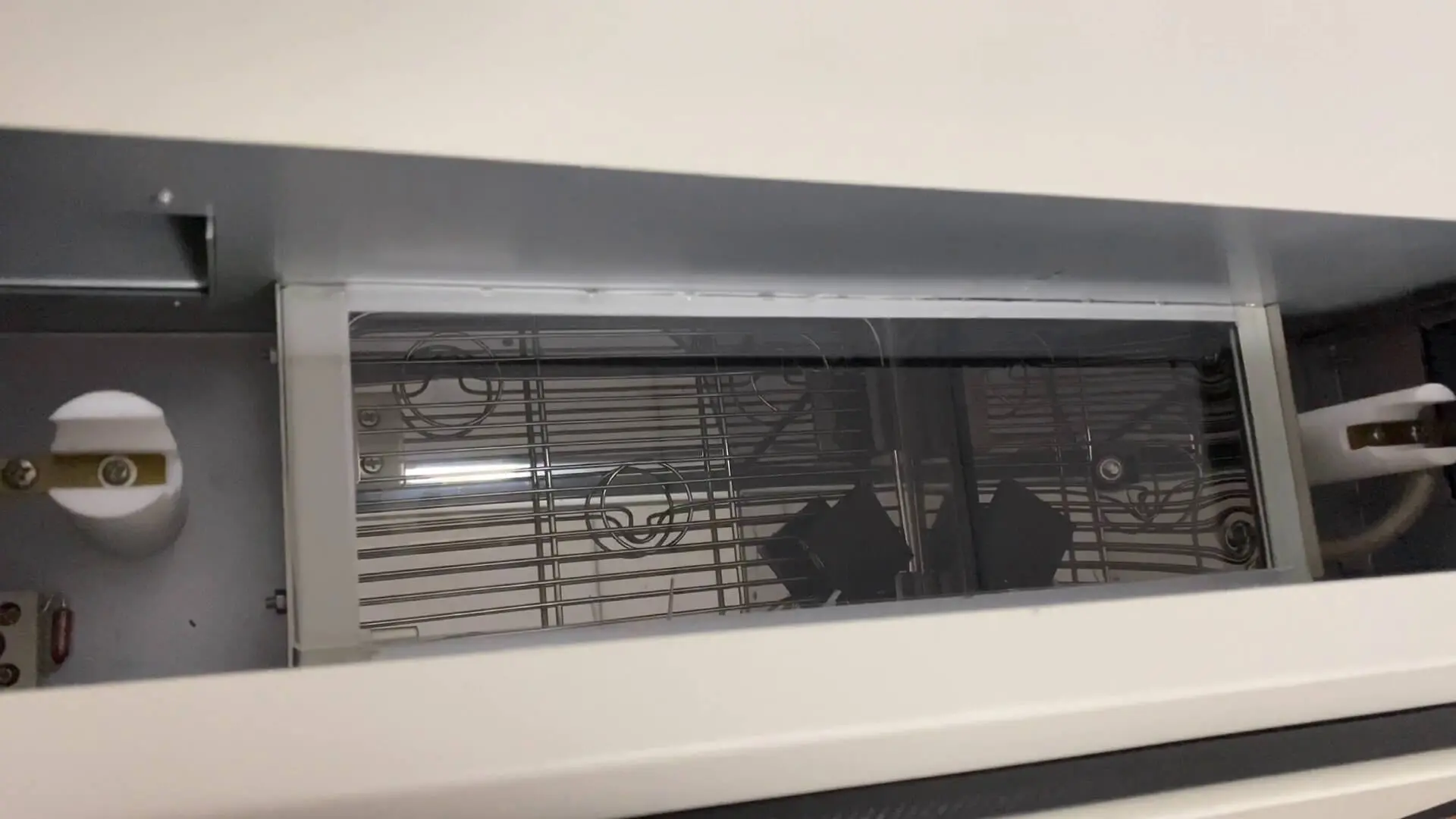

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Home

Home