- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Washing Colorfastness Tester for Textiles

Overview

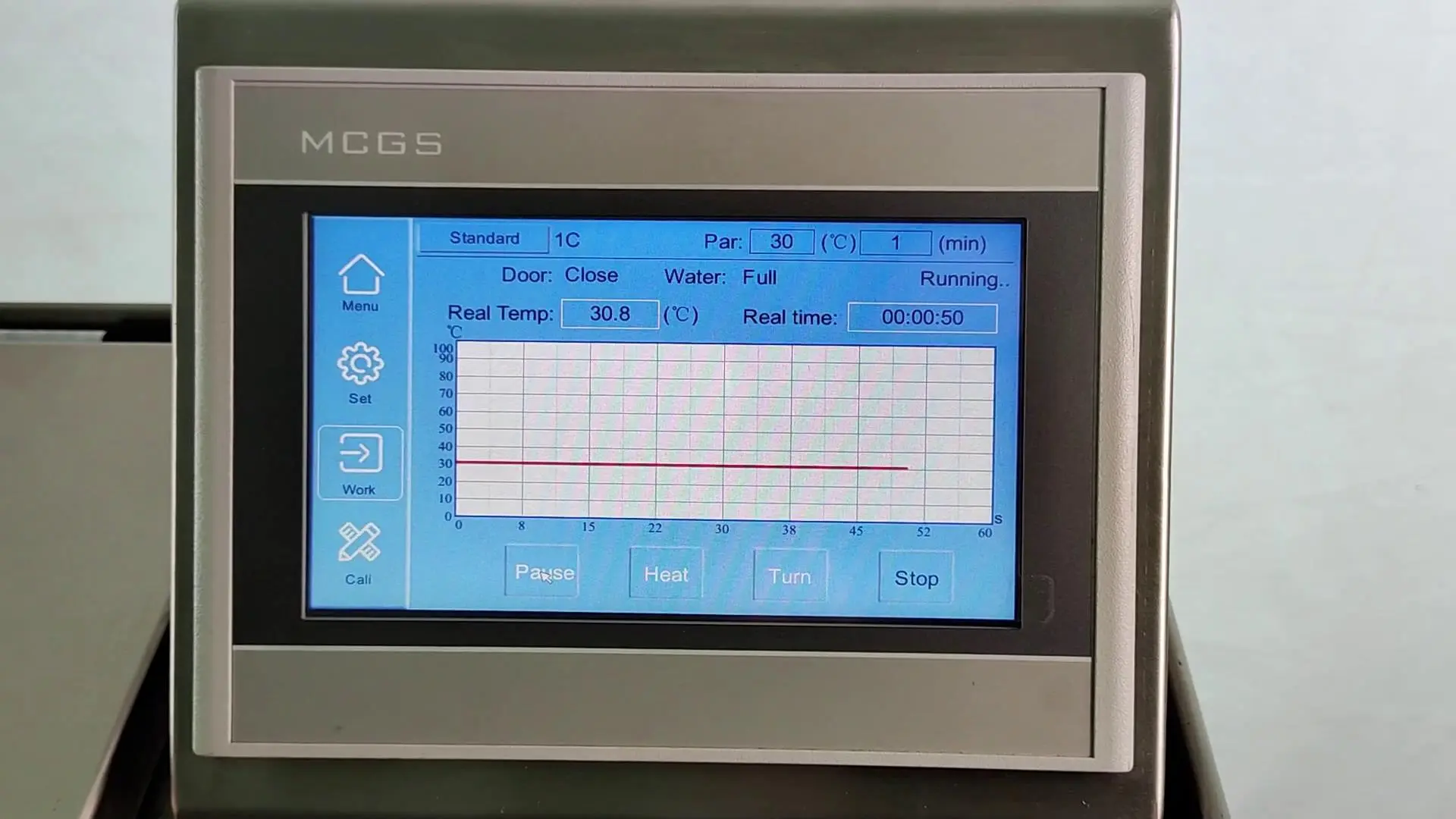

The instrument is designed by drawing on the advantages of similar instruments at home and abroad. The display uses a color touch screen. The interface is simple to understand, easy to operate and sensitive to click.The fuselage uses 304 stainless steel, the appearance is simple and generous.The rotating structure adopts low noise reducer and synchronous belt, running smoothly and with low noise. PID algorithm is adopted for temperature control. The heating speed is fast and the control fluctuation is small.

Application

Standards

ISO105-C01, C02, C03, C04, C05, C06, C08, C09, C10, D01, E03, E12

AATCC 3, 61, 62, 86, 132, 151, 162, 190; GB/T 5711, GB/T3921-1 ~ 5, GB/T 12490

Key Parameters

| Washing cups | A(AATCC cup volume): 1200±50ml B(ISO cup volume): 550±50ml | ||||||

| Washing cups | Model No. | D007E-12B | D007E-6AB | D007E-20B | D007E-10AB | D007E-24B | D007E-12AB |

| Combination | 12B | 6A+6B | 20B | 10A+10B | 24B | 12A+12B | |

| Water inflow and drain design | Automatically | ||||||

| Display | Touch screen display | ||||||

| Rotation speed | 40±2 rpm | ||||||

| Timing range | 1~999min | ||||||

| Temperature range | Room temp. to 99 centigrade degree | ||||||

| Temperature fluctuation | <±1 centigrade degree | ||||||

| Heating methods | Electrical heating tube | ||||||

| Power supply | 3∮AC 380V 50/60HZ 5KW | ||||||

Product Details

Production Processes

Scenarios of Use

Operation

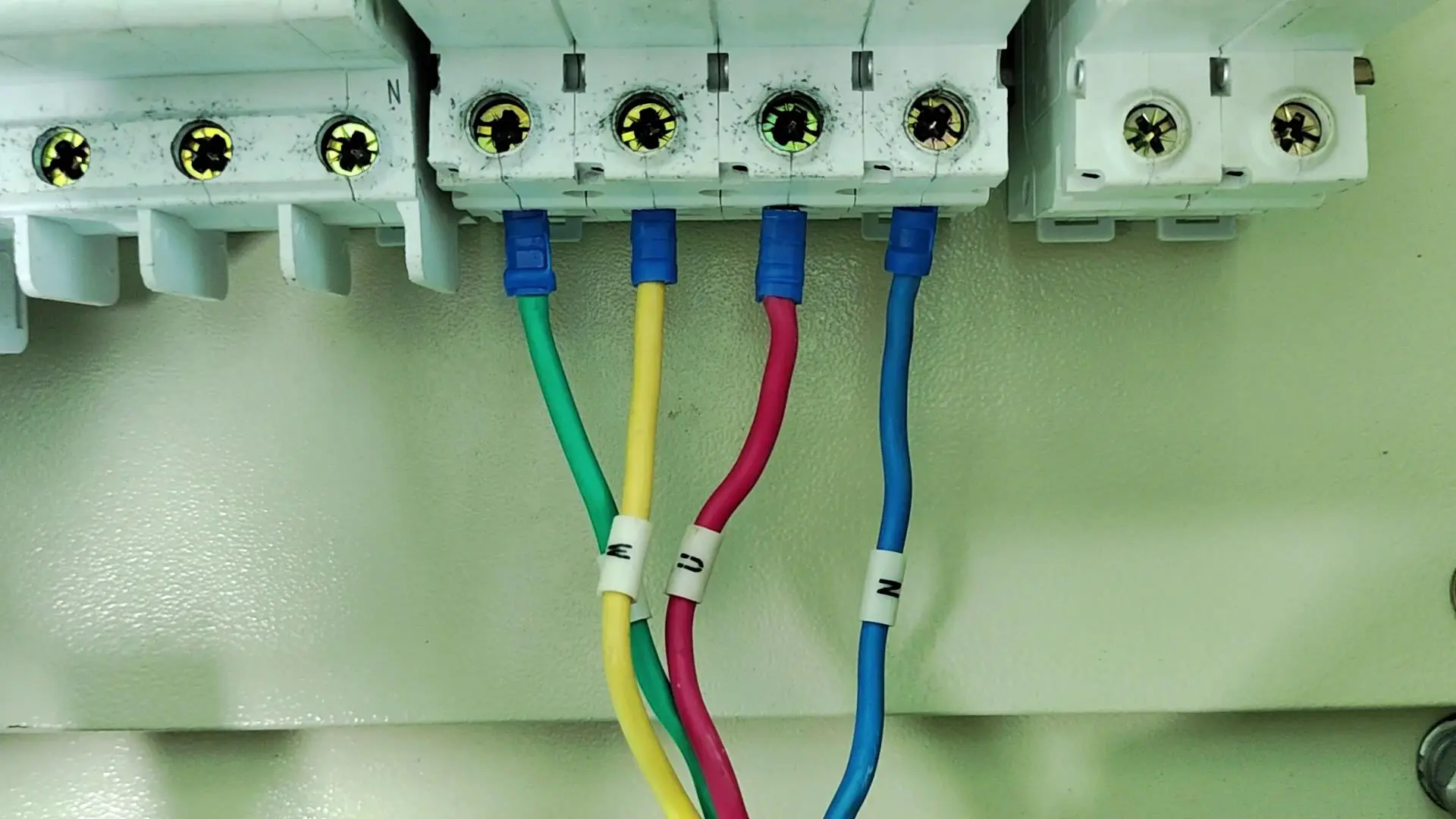

The power supply connection

The power supply of the instrument is required to be AC380V/50HZ (three-phase five-wire system).

Must connect ground wire.

Turn on the power switch

Check without error before starting test. Check whether the N cable connection is correct before powering on the device.

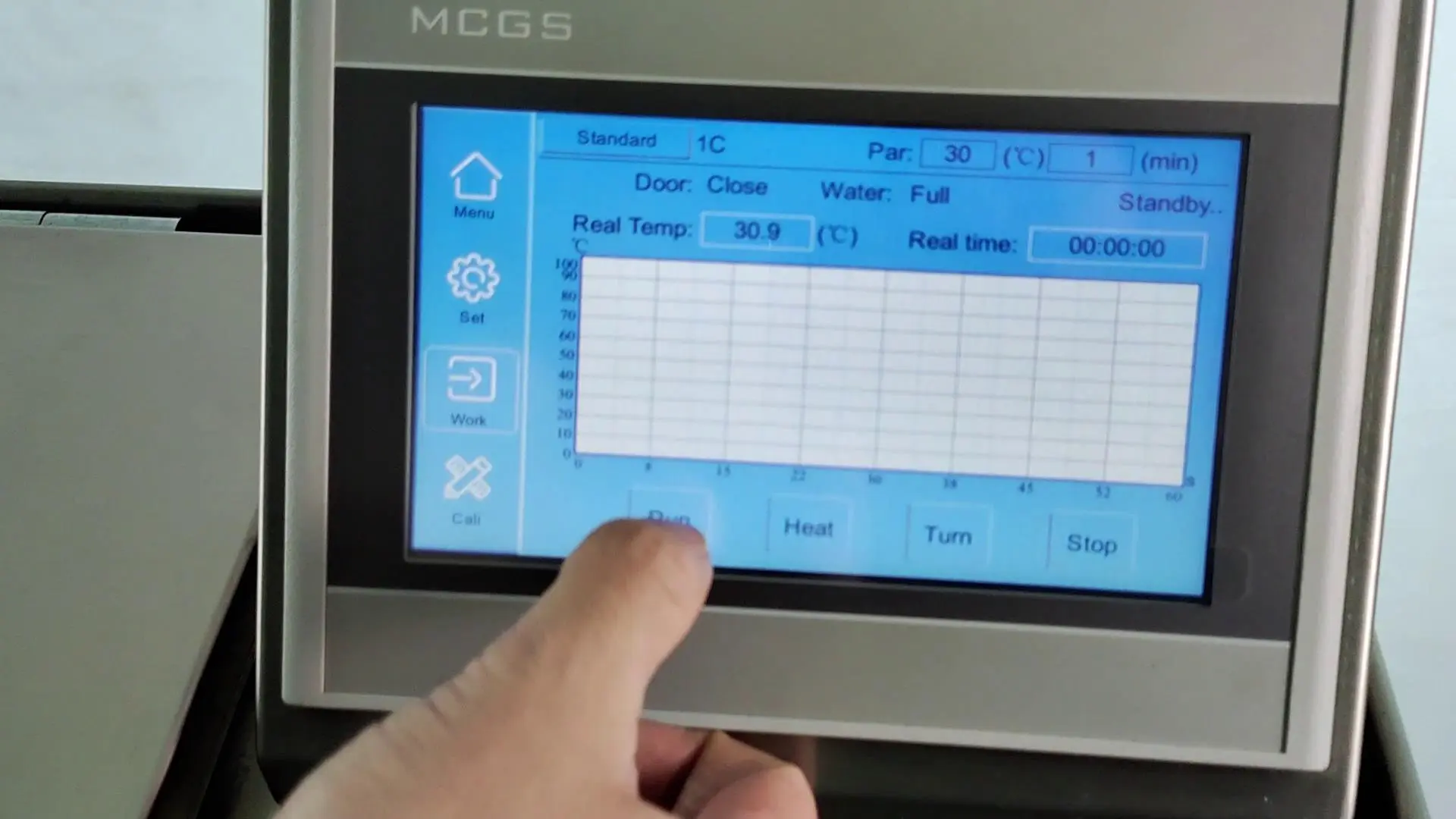

Setting parameters

click the button [GB/T 3921. a1-e5], [AATCC61.1 a-5a] to switch the corresponding parameters of the standard, 1C to 3C for customers to set items freely.

Open the bin cover switch

When the bin cover is opened, the left pole slides backwards until it slides into the card slot, i.e.

Add water

The water added into the test chamber, water level should be below the bearing to protect bearing.

Heat water

Press the heating button to heat the water until the water temperature reaches the preset temperature to stop heating.

Prepare sample

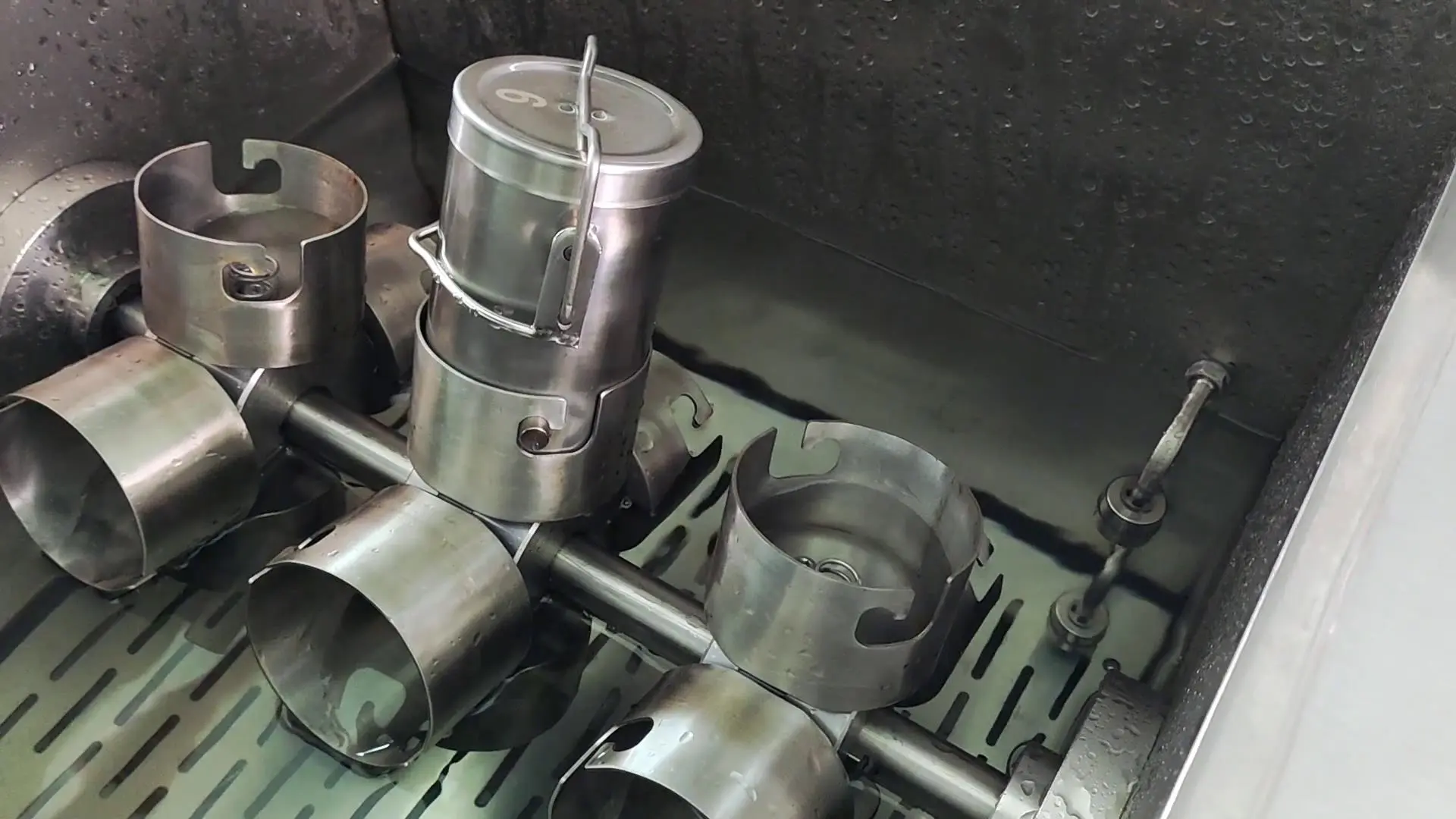

Pour the prepared solution into the cup according to the specified volume.Put the sample into the sample cup, cover the lid, press the sample cup with the pressure ring.

Test cup installation

put the sample cup into the cup holder, press the sample cup, and then rotate the test cup clockwise to complete the installation of the sample cup.

Dawing a curve

The instrument motor rotates, the heating tube heats up, and the temperature/time curve begins to be drawn.

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home