- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

Water Impact Penetration Testing Machine Rainproof Clothing Impact Performance Tester M127

Overview

Application

Standards

Key Parameters

|

Model |

M127 |

|

Height of round bathtub from the ground |

≥5000mm; |

|

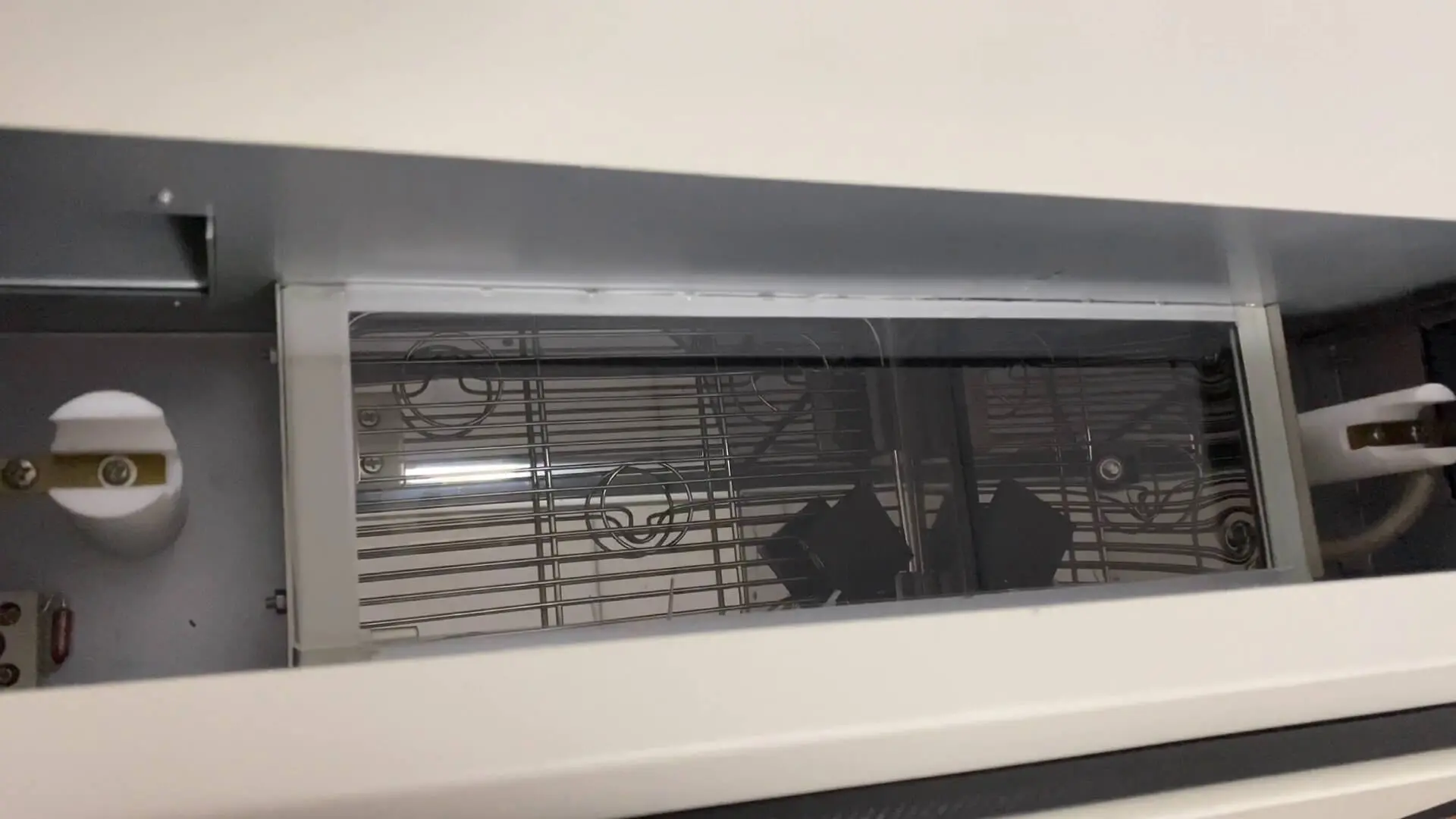

There are nozzles installed at the bottom of the circular bathtub |

682 (1000/m2), the hole diameter is 0.6mm, and the center distance between the nozzles is 34mm; |

|

The water level height of the circular bathtub is |

(45±5) mm. If it is higher than 45mm, there is an overflow port; |

|

Water droplet diameter |

about 5mm; water flow rate: (450±50)L/(m2×h); |

|

Temperature sensor measurement range |

≤100℃, resolution 0.1℃, accuracy: ±0.5℃; |

|

Human body model: |

Height: (1820±40)mm;Chest circumference: (1000±60) mm;Back tilt angle: (0~10)°;The angle between the arm and the true vertical direction: (20~30)°;Includes: head, torso, abdomen, buttocks, arms, hands, straight legs and feet, arms are movable; |

|

Humidity sensor |

Quantity: 25 lines;Measuring range: (20~99)%RH; |

|

Test time |

<100 hours; |

|

Overall dimensions (L×W×H) |

1300mm×1300mm×5500mm; |

|

Weight |

about 300Kg; |

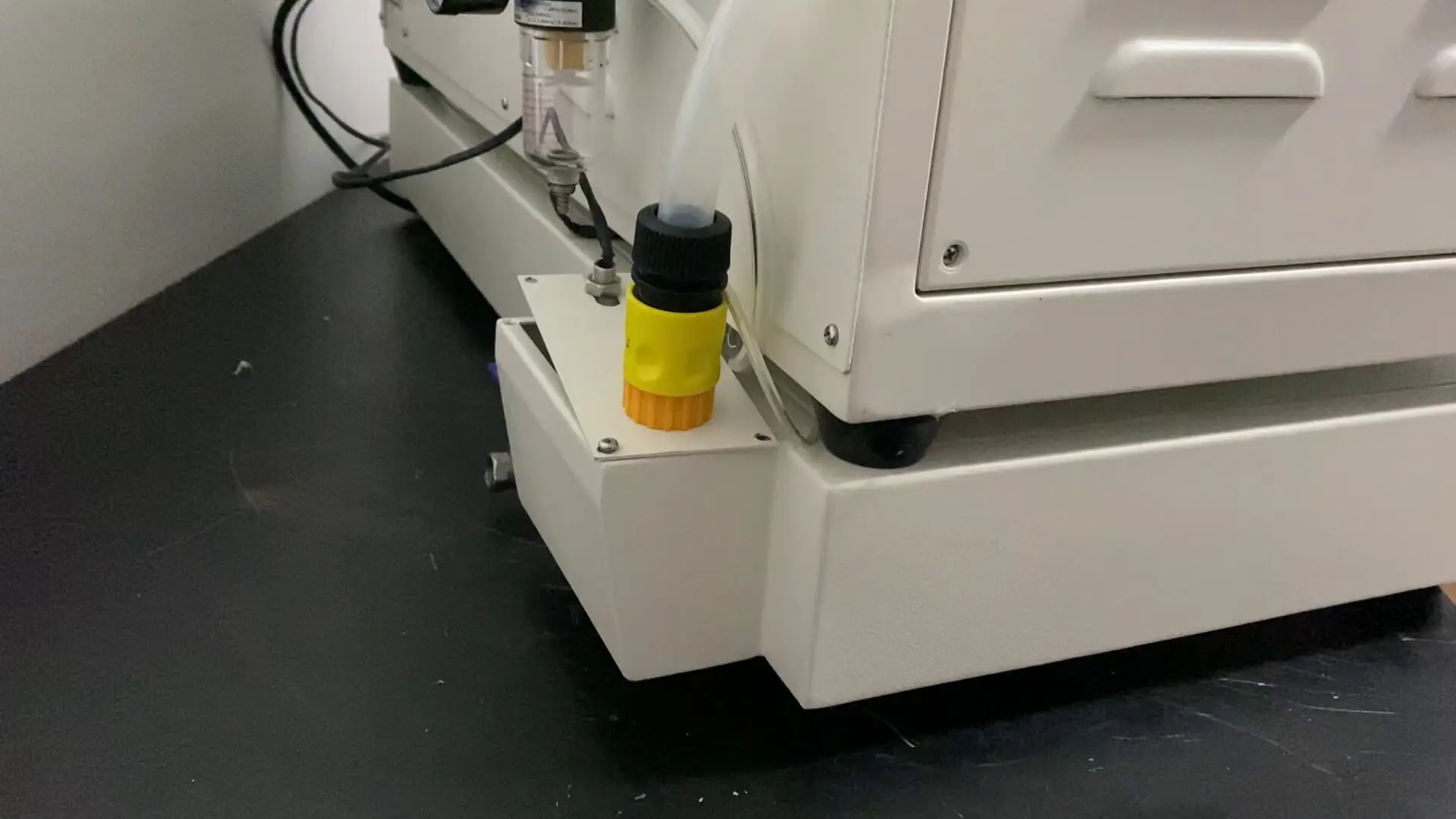

Product Details

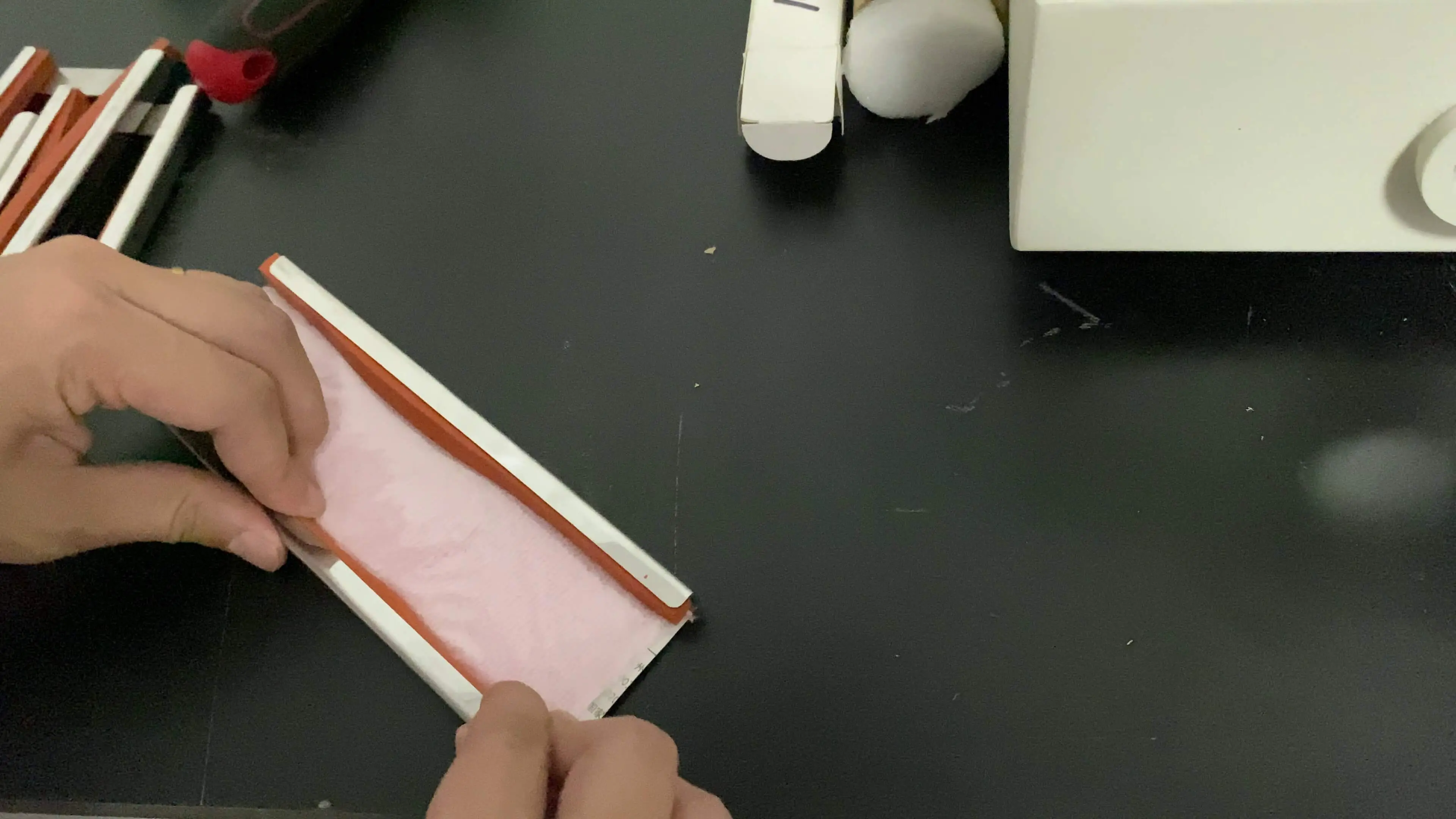

Production Processes

Scenarios of Use

Operation

Transportation

Home

Home