- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Yarn Lab Equipment Dyeing Test Braiding Machine Y027

Overview

Dyeing test knitting machine is the latest generation of high efficiency knitting machine carefully developed by our factory, which has the advanced international level in the new century. The mechanical properties of this machine are stable and reliable. The storage part of this machine is the most advanced single row wire storage device, and the control system is computerized. The preferred dyeing test equipment for weaving mills.

Application

Standards

Standards

Number of needles used in the machine

|

Raw material denier(dtex) |

Number of knitting needles |

|

Below 20 |

320 |

|

25~40 |

300 |

|

35-65 |

280 |

|

50-100 |

260 |

|

75- 150 |

240 |

|

150 - 350 |

176 |

|

Above 300 |

144 |

Key Parameters

|

Model |

Y027 |

|

Machine caliber |

89mm(3.1/2’') |

|

Rotary speed |

300 rpm |

|

Production capacity |

In continuous weaving mode, it takes only 11 seconds to weave a 5 cm section and 325 sections per hour. In continuous weaving mode, it takes 230 sections per hour. |

|

Size |

360x720x1450mm(L x W x H) |

|

Weight |

85kg |

|

Power |

300W |

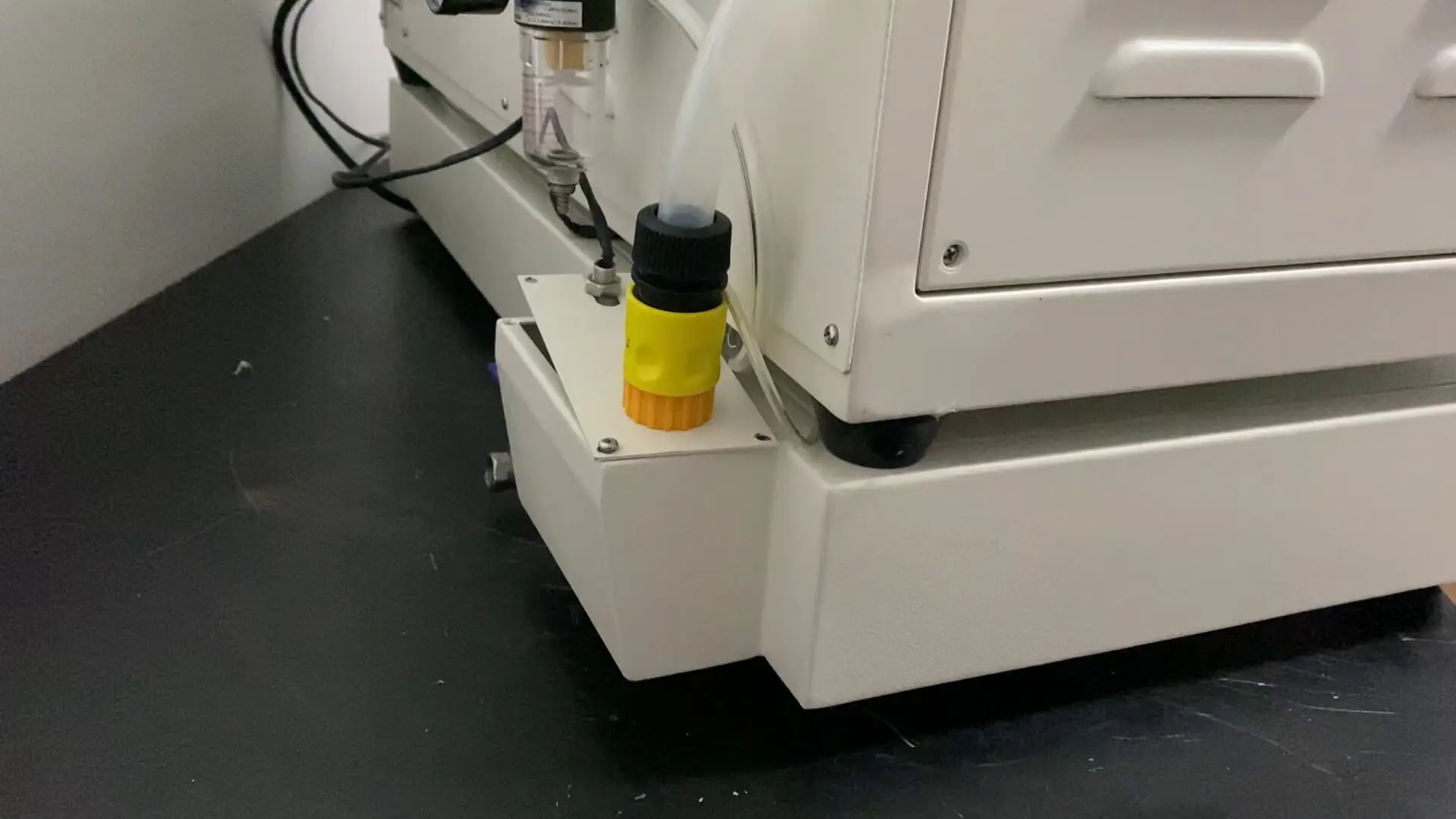

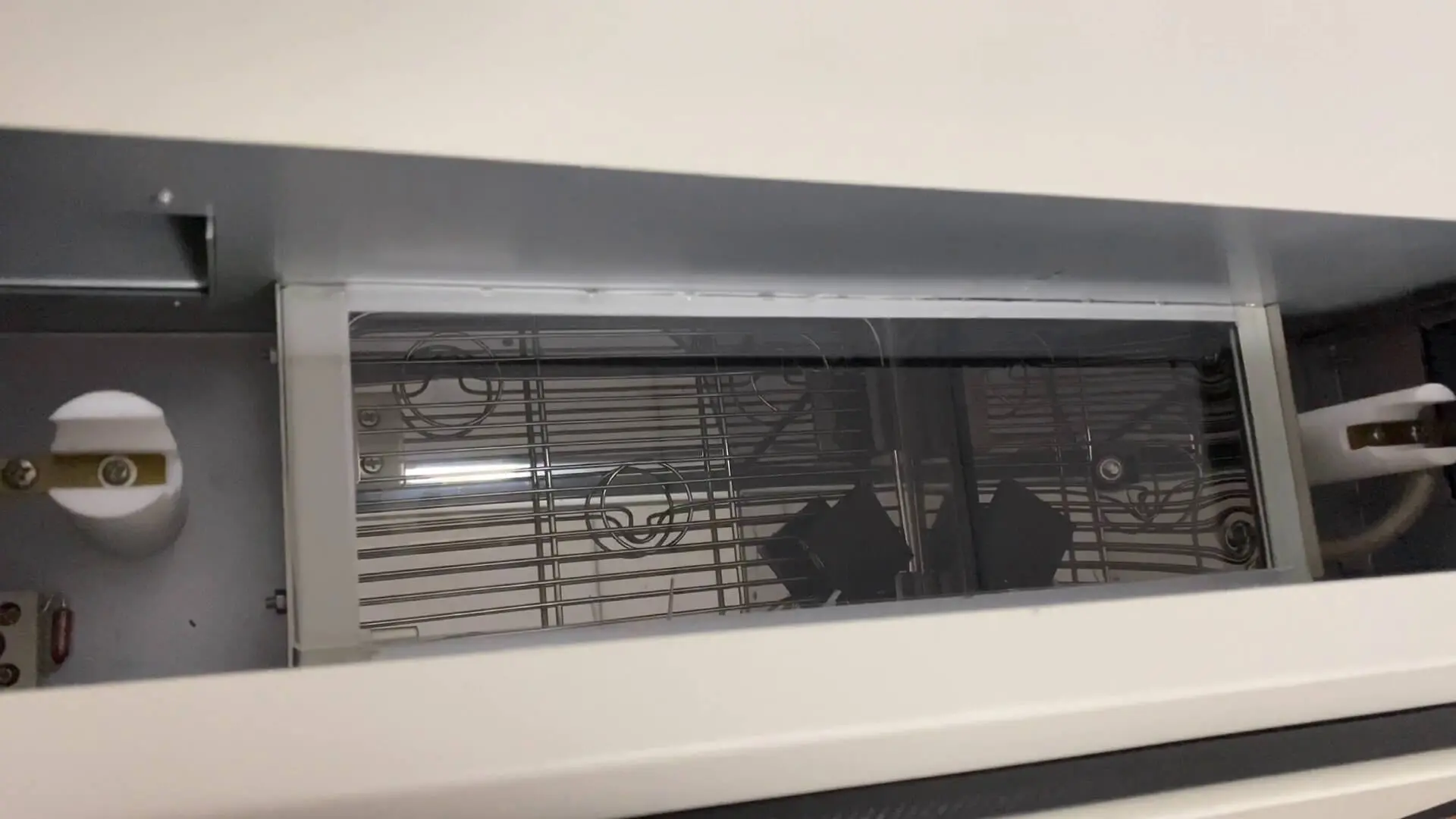

Product Details

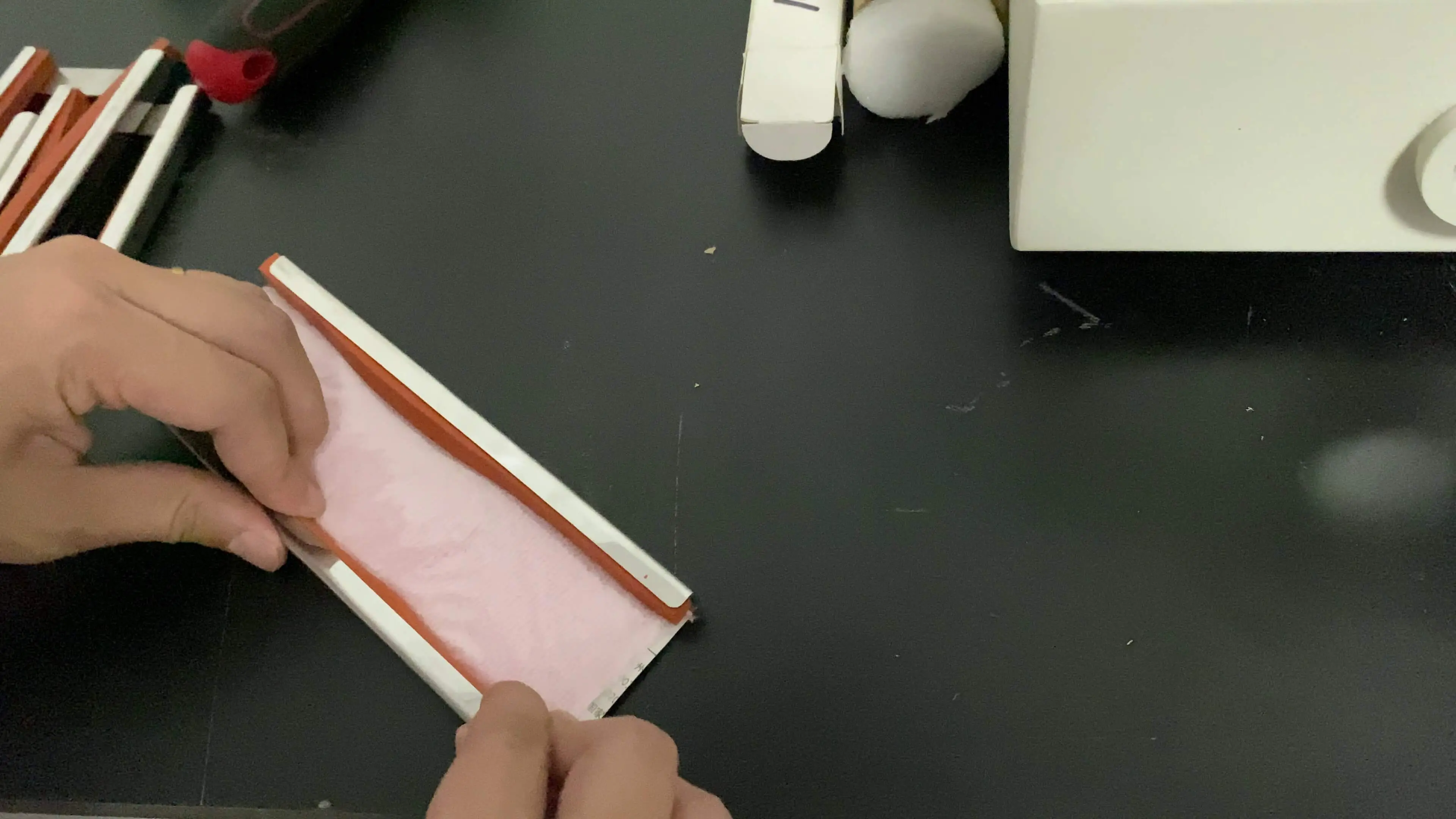

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home