- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

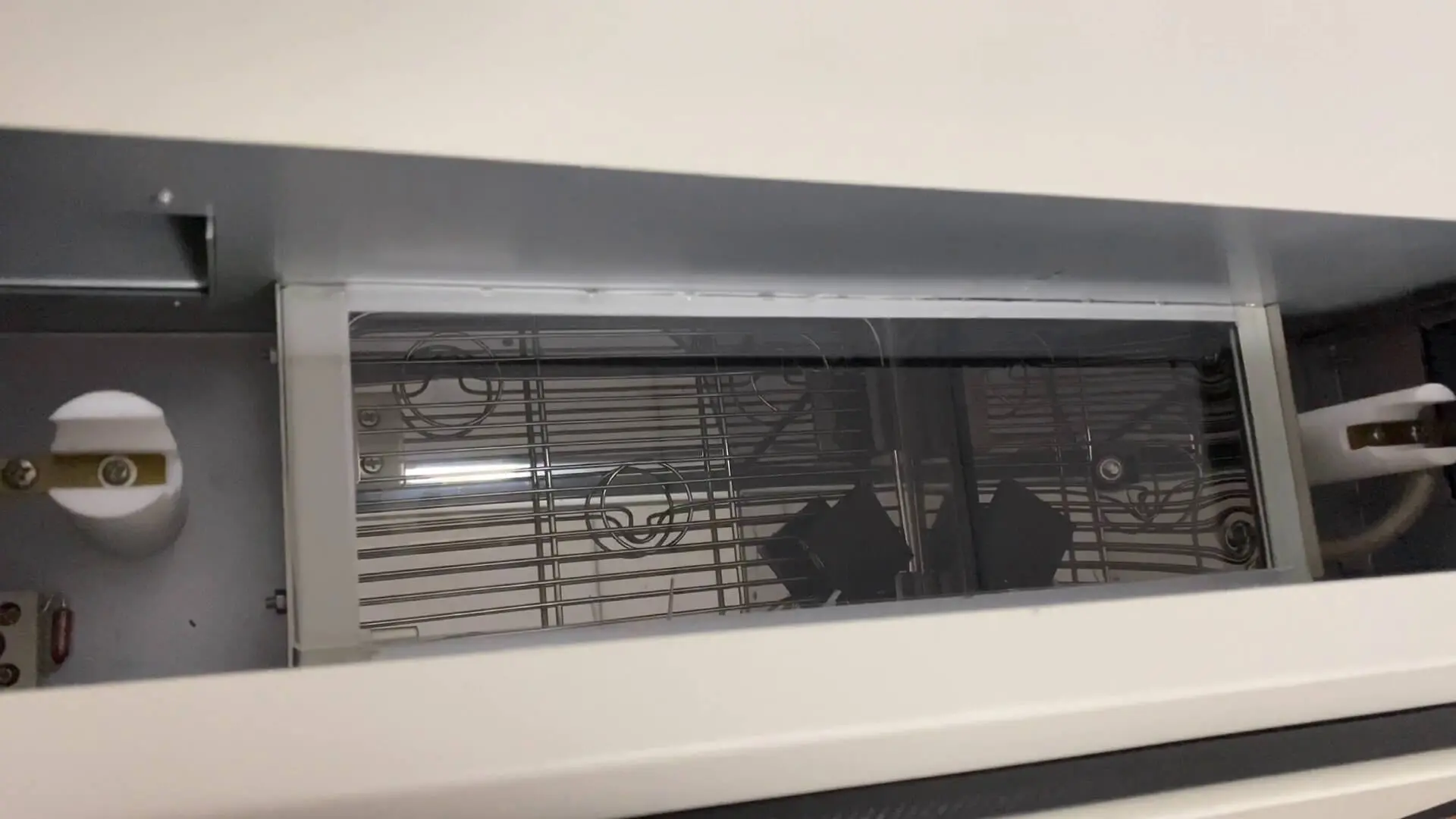

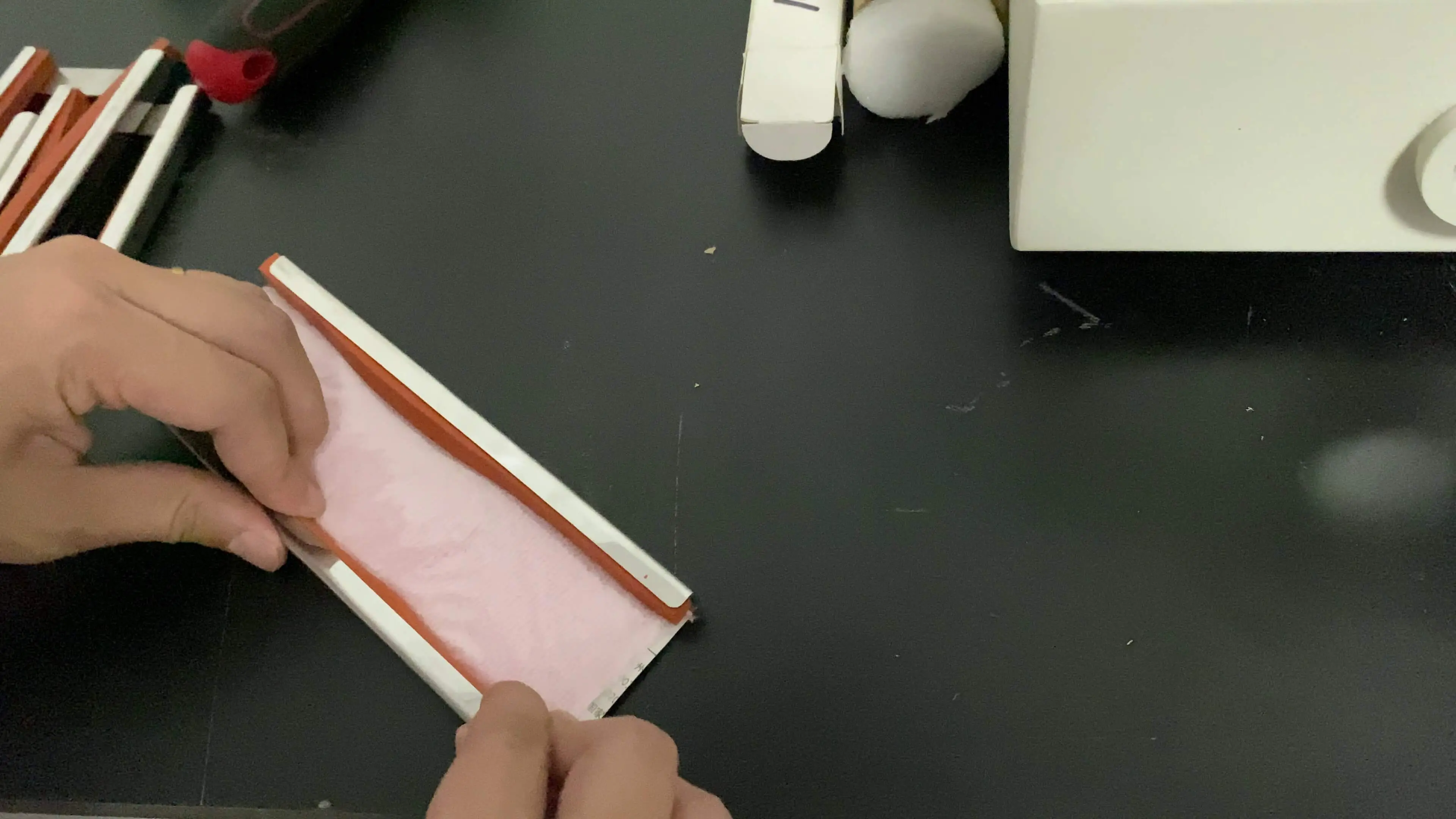

Yarn Sliver and Roving Evenness Tester (Without Hairiness Function) Y010E

Overview

Application

Standards

Key Parameters

|

Model |

Y010E |

|

Test Slot |

4 |

|

Test range |

4tex~12k tex |

|

Evenness test speed |

4, 8, 25, 50, 100, 200, 400, 800m/min |

|

Test time |

Freely setting between 10Sec~20min |

|

CV%, U% value range |

0.2%-100% |

|

Variation - Length curve |

Cutting length 1cm-1500m |

|

Defect value |

Simultaneously output 12 grades’ defect value Thin: -30%, -40%, -50%, -60% Thick: +35%, +50%, +70%, +100% Nep: +140%, +200%, +280%, +400% |

|

Wave spectrogram |

170 channels, wavelength 1cm-2950m |

|

The frequency distribution of the linear density |

-100~+100%, +100%~+400% |

|

Drift rate (DR%) value |

Output DR(1m, +5%), DR. (1m, -5%), DR(20cm, +35%) DR(20cm, -30%), 4 DR % Value |

|

A single group of measurement times |

≦20, can simultaneously measure two varieties Same type: Maximum 10 groups including 200 tubes data statistic |

|

Power supply |

220V±10% 50Hz±5Hz ≤500VA |

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Home

Home